Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

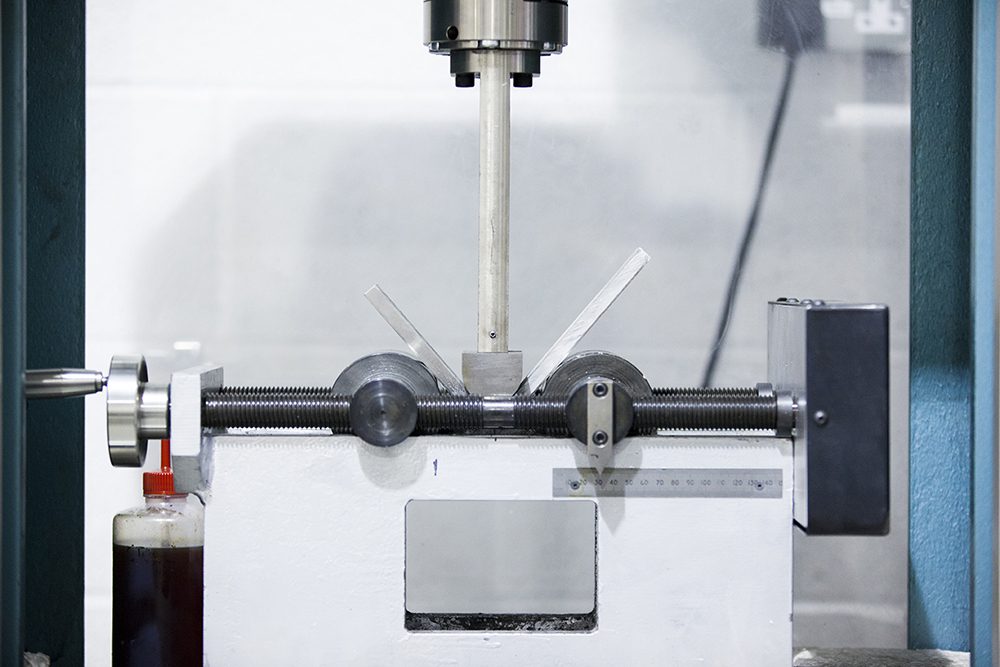

Fracture Analysis

Our expert team specialises in providing comprehensive fracture analysis solutions to industries ranging from aerospace and automotive to manufacturing and materials research

Fractures can happen when a material experiences excessive loading, fatigue, or stress during service. Examining fractures and investigating why it happened is an essential step in fracture analysis, as it offers important insights into the reasons behind the breakage.

To determine the root cause of the fracture and identify any material defects or imperfections within the structure, we employ various testing techniques such as fracture analysis, fractography, and other in-depth examinations.

Unravel the mysteries of fractures in metal components with our expert fracture analysis services!

Get in touch today! Get in touch today! Get in touch today!Our Fracture Analysis techniques

Failure Investigations

Fracture analysis uses failure investigation to determine the circumstances surrounding a fracture, including the conditions under which it occurred and the history of the component. It also involves gathering information about the operating conditions leading up to the failure.

By examining the fracture surface, the specific mechanism of failure can be determined. Different fracture mechanisms in metals can be analysed through fracture analysis, and may include:

- Ductile fracture

- Brittle fracture

- Fatigue failure

- Stress corrosion cracking

- Hydrogen embrittlement

The main goal of fracture analysis is to identify the root cause or causes of the failure. This requires considering factors such as design flaws, material defects, manufacturing processes, and environmental and operational conditions.

Get in touch!Fractography

Fractography testing techniques aim to identify the fracture morphology of a component and gain insights into the fracture mechanism.

Fractography plays a crucial role in analysing the fracture surface for damage and cracks. When a material is fractured or broken, it exhibits certain characteristics on the surface that indicate signs of failure. These characteristics may include

- Ductile dimples

- intergranular cracking,

- fatigue-induced scratches or grooves,

- cleavage of the material.

Fractography allows us to uncover any underlying imperfections, defects, or flaws within the material. Identifying these flaws is essential as they can have implications for future manufacturing processes and may lead to further failures in real-service conditions. By analysing and addressing these underlying imperfections, we assist our customers in enhancing the design, safety, and longevity of their products.

Get in touch!Material Characterisation

Fracture analysis often involves conducting chemical analysis and mechanical tests to identify the grade and composition of the material and assess the mechanical and physical properties of the metal.

Through chemical analysis testing, we can identify the elemental composition of the material, which helps us to determine if the material being used is appropriate for the service conditions, and that it meets the required standards or regulations for use.

Get in touch!Strength Testing

Testing the durability of a material is an essential aspect of examining fractures. When a material possesses great strength, the chances of it fracturing or breaking during use are significantly reduced.

However if a material is weak or brittle, it is highly susceptible to breaking under stress or fatigue. Brittle fractures can occur suddenly and without warning, potentially leading to catastrophic consequences upon failure.

By analysing the strength and toughness of the material, we gain insights into its limitations and points of vulnerability. This valuable information helps determine whether the material is suitable for a specific application or service condition.

We use a variety of mechanical test methods to assess the material’s strength and durability, such as tensile testing, hardness and microhardness testing, impact testing, and bend testing.

Get in touch!

What causes fractures in metals?

Fractures can occur in metals due to a variety of reasons, ranging from material defects and environmental conditions to applied stresses and operational factors.

Here are some common reasons why fractures happen in metals:

- Overloading or prolonged stress that exceeds the material’s strength

- Material defects such as inclusions or impurities caused by manufacturing processes

- Fatigue failures from repeated cyclic loading below the material’s ultimate strength

- Brittle fractures caused by low temperatures, high strain rates, or the presence of hydrogen

- Environmental conditions, such as temperature, humidity, chemical exposure, and corrosion,

- Processing Defects such as improper heat treatment, forging defects, casting porosity, or insufficient material thickness.

- Poor design choices, such as sharp corners, abrupt changes in geometry, or inadequate fillets, can create stress concentrations that promote crack initiation and propagation. 8.

- Metals can fracture under sudden impact or shock loading, especially if they are not designed to withstand such loading conditions.

Understanding the underlying mechanisms and factors contributing to fractures in metals is crucial for implementing preventive measures and ensuring the reliability and safety of metal components and structures in various applications.