Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

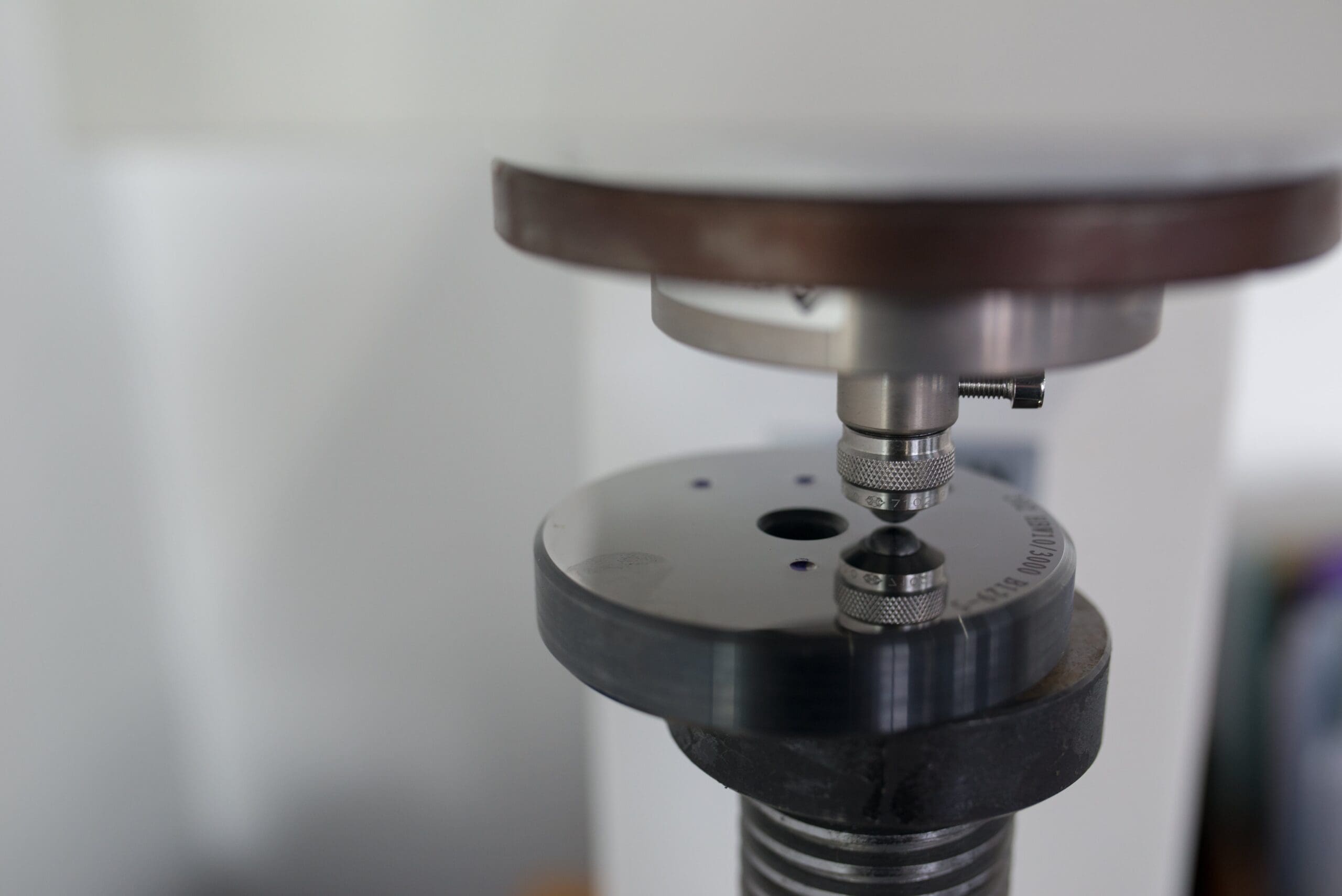

Brinell Hardness Testing

The Brinell technique is considered one of the oldest methods for measuring hardness and is especially useful for analysing forgings, castings, and larger, rough samples of materials.

By using a larger indenter, Brinell testing effectively reduces the impact of localized structural differences and surface irregularities.

The Brinell Hardness test is a commonly used procedure for materials with a rough structure, like cast irons or forged metal samples. It involves using a 5mm or 10mm round carbide ball to create an indentation in the material, applying a high test load (usually 750kg and 3000kg). The indentation is then measured and analysed using a microscope to determine the average result on the Brinell Hardness Number scale.

Brinell Hardness Testing standards and specifications we work with:

- 5mm ball diameter and 750kg load

- 10mm ball diameter and 3000kg load

- BS EN ISO 6506-1:2014

- ASTM E10:18

Do you need accurate and reliable hardness test results?

Get in touch today! Get in touch today! Get in touch today!

Common uses for Brinell Hardness Testing

Brinell hardness testing is used in various industries, including manufacturing, metallurgy, and quality control, to evaluate the hardness of metallic materials, especially in scenarios involving larger samples, forgings, castings, and bulk metal assessments.

- Forgings and Castings: Brinell hardness testing is ideal for testing forgings, castings, and larger coarse samples of materials. The method’s ability to accommodate larger sample sizes makes it suitable for assessing the hardness of components produced through forging and casting processes.

- Bulk Metal Hardness Determinations: Brinell testing is often employed for bulk metal hardness determinations. It provides a measure of the overall hardness of a material, making it useful in quality control and material selection.

- Non-ferrous Metals: Brinell hardness testing is applicable to a wide range of metals, including non-ferrous metals. It allows for the evaluation of hardness in materials such as aluminium, copper, and brass.

- Pre-heat Treated Steel: The Brinell method is frequently used to assess the hardness of pre-heat treated steel. This is important in industries where heat treatment is a critical step in the manufacturing process to achieve desired mechanical properties.

- Comparative Hardness Testing: When consistency in hardness readings is crucial, Brinell testing is preferred over some other hardness testing methods. It helps minimise the influence of localised structural differences and surface irregularities on the test results.

- Average Hardness Assessment: Brinell hardness testing makes a relatively deep and wide indentation in the material, providing an average hardness measurement over a larger surface area. This can be advantageous when seeking an overall understanding of the material’s hardness.