Destructive Testing

Hardness Testing

We take pride in our varied range of hardness testing services, offering precise and reliable assessments using industry-standard methodologies.

Explore our process

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with...

A snapshot of our Hardness Testing services

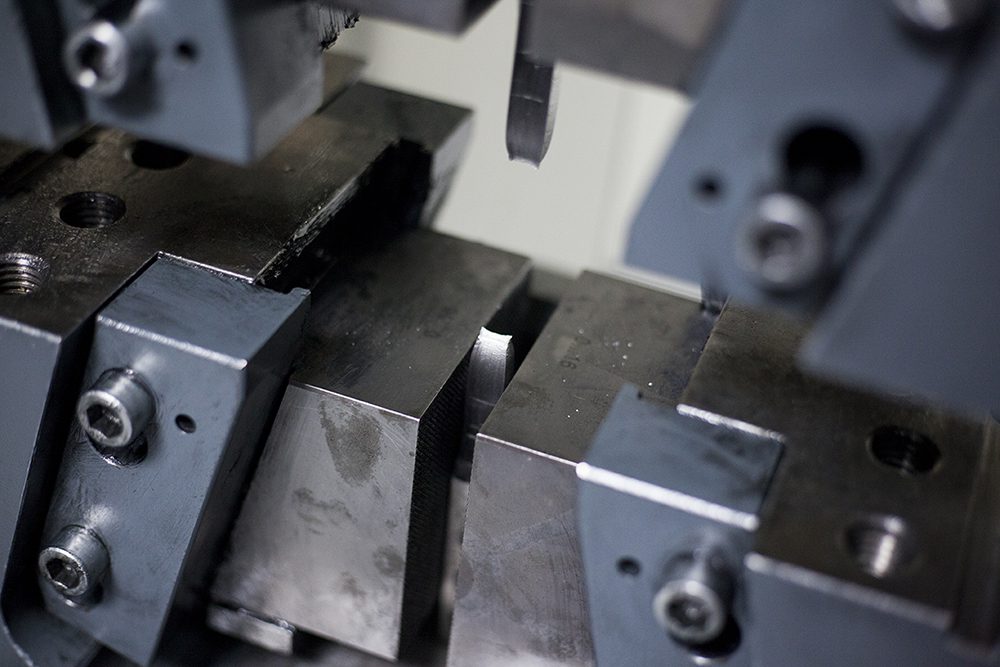

Hardness Testing on metals is used to evaluate the resistance of a metal to deformation or permanent damage, specifically in terms of indentations or scratching. It involves applying a consistent force using a rounded or pointed object under controlled conditions to create a small dent on the surface of a metal. The size of the dent is then measured to determine the hardness of the material.

Brinell Hardness Testing

Ideal for testing coarse materials like forgings and castings to measure resistance to deformation.

Rockwell Hardness Testing

Quick and efficient hardness testing for metals and alloys, offering different scales for a wide range of applications.

Vickers Hardness Testing

Precise hardness testing using a diamond pyramid indenter, perfect for small or thin samples.

Microhardness Testing

Highly accurate testing for small-scale or delicate samples, ideal for coatings and microstructural analysis.

Let's talk about Hardness Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Hardness Testing at BES Group

Explore all sub-services- On-site NDT Hardness Testing

- All your Destructive Metals Testing needs, under one roof.

- Key benefits of Hardness Testing

Non-Destructive Hardness Testing for precise measurements in hard to reach areas

In addition to our Destructive Hardness Testing services, we also offer convenient on-site NDT Hardness Testing using industry-leading equipment.

We offer Non-Destructive Hardness Testing to NACE MR-01-75 (ISO 15156) using portable Krautkramer MIC10-DL hardness testers. The small arrow probes allow our technicians to take precise measurements even in hard-to-reach areas.

This advanced technology is suitable for:

- Heavy, fixed components

- Difficult to access locations

- Series parts during production

- Material identification

- A range of materials including solid, coarse-grained objects, forged parts with homogeneous surface structures, and cast items

We also carry out Barcol Hardness Testing to determine the hardness of reinforced and non-reinforced plastics. Our NDT testing team is equipped with various types of portable hardness testing machines, ensuring flexibility and accuracy in different scenarios.

We’re here to take care of all your metals testing needs, under one roof.

We understand the frustration of sending samples to multiple labs for different tests, which can be costly and lead to inconsistent results.

We aim to complete our full suite of destructive tests within a 3-day turnaround, which includes:

- Full machining and preparation of samples

- Tensile, Impact and Hardness Testing

- Chemical Analysis

- Metallurgical Examinations

- Corrosion Analysis

- Optional services include Salt Spray Testing, Weld Assessments and Coating Finish Testing.

With our full suite of tests, we conduct a thorough examination of your sample’s properties, structure, and behaviour. Our in-house workshop prepares the samples, which are then tested in our UKAS accredited laboratory. This ensures that your samples receive a comprehensive and professional service from start to finish, without the hassle of using multiple laboratories.

To ensure efficient tracking, each sample is given a unique barcode to book all your samples into our laboratory. This allows us to monitor each sample from the moment it arrives, throughout the testing process, until its completion.

Material Strength Assessment

Hardness Testing provides valuable information of a material’s resistance to deformation, a gives and insight into its strength and durability. This is crucial for ensuring that materials meet the required mechanical properties for specific applications.

Quality Control

Hardness Tests are integral to quality control processes, allowing manufacturers to verify the consistency and reliability of materials. This helps ensure that products meet industry standards and specifications.

Process Optimisation

Hardness Testing is used to optimise heat treatment processes. It helps determine the effectiveness of heat treatments in achieving the desired hardness levels, leading to improved material performance.

-

On-site NDT Hardness Testing

Non-Destructive Hardness Testing for precise measurements in hard to reach areas

In addition to our Destructive Hardness Testing services, we also offer convenient on-site NDT Hardness Testing using industry-leading equipment.

We offer Non-Destructive Hardness Testing to NACE MR-01-75 (ISO 15156) using portable Krautkramer MIC10-DL hardness testers. The small arrow probes allow our technicians to take precise measurements even in hard-to-reach areas.

This advanced technology is suitable for:

- Heavy, fixed components

- Difficult to access locations

- Series parts during production

- Material identification

- A range of materials including solid, coarse-grained objects, forged parts with homogeneous surface structures, and cast items

We also carry out Barcol Hardness Testing to determine the hardness of reinforced and non-reinforced plastics. Our NDT testing team is equipped with various types of portable hardness testing machines, ensuring flexibility and accuracy in different scenarios.

-

All your Destructive Metals Testing needs, under one roof.

We’re here to take care of all your metals testing needs, under one roof.

We understand the frustration of sending samples to multiple labs for different tests, which can be costly and lead to inconsistent results.

We aim to complete our full suite of destructive tests within a 3-day turnaround, which includes:

- Full machining and preparation of samples

- Tensile, Impact and Hardness Testing

- Chemical Analysis

- Metallurgical Examinations

- Corrosion Analysis

- Optional services include Salt Spray Testing, Weld Assessments and Coating Finish Testing.

With our full suite of tests, we conduct a thorough examination of your sample’s properties, structure, and behaviour. Our in-house workshop prepares the samples, which are then tested in our UKAS accredited laboratory. This ensures that your samples receive a comprehensive and professional service from start to finish, without the hassle of using multiple laboratories.

To ensure efficient tracking, each sample is given a unique barcode to book all your samples into our laboratory. This allows us to monitor each sample from the moment it arrives, throughout the testing process, until its completion.

-

Key benefits of Hardness Testing

Material Strength Assessment

Hardness Testing provides valuable information of a material’s resistance to deformation, a gives and insight into its strength and durability. This is crucial for ensuring that materials meet the required mechanical properties for specific applications.

Quality Control

Hardness Tests are integral to quality control processes, allowing manufacturers to verify the consistency and reliability of materials. This helps ensure that products meet industry standards and specifications.

Process Optimisation

Hardness Testing is used to optimise heat treatment processes. It helps determine the effectiveness of heat treatments in achieving the desired hardness levels, leading to improved material performance.

Frequently asked questions

What types of Hardness Testing do you offer?

We offer various hardness testing methods, including Brinell, Rockwell, Vickers, and Microhardness testing. Each method is suited to different materials and sample sizes, ensuring you get the most accurate results.

How do I know which Hardness Test is right for my material?

The best test depends on your material type, sample size, and the level of precision required. Our team can help guide you to choose the appropriate test based on your needs and provide expert advice for optimal results.

What is the turnaround time for Hardness Testing?

Our typical turnaround time for a full suite of Destructive Tests is within 3 days, including sample preparation, testing, and reporting. We prioritise efficiency while maintaining the highest standards of accuracy.

Can I combine Hardness Testing with other tests?

Yes, we offer comprehensive testing packages. Hardness Testing can be combined with other Mechanical Tests, Chemical Analysis, and Metallurgical Examinations for a complete understanding of your material’s properties.

Are your Hardness Testing services accredited?

Yes, we use a UKAS-accredited laboratory to perform our Hardness Testing, ensuring that all results meet international standards for accuracy and reliability.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team