Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

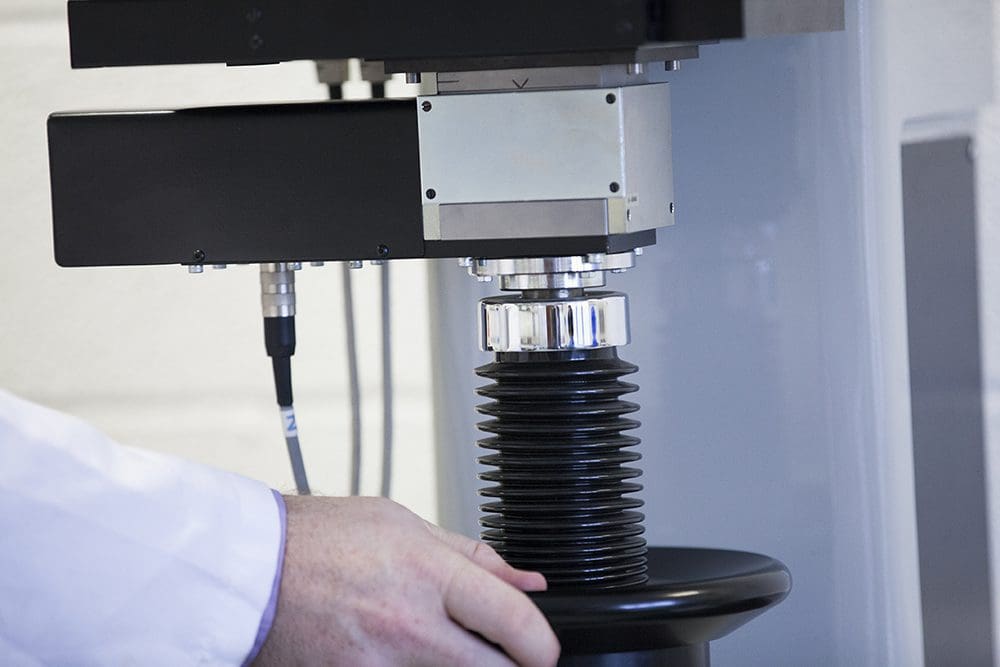

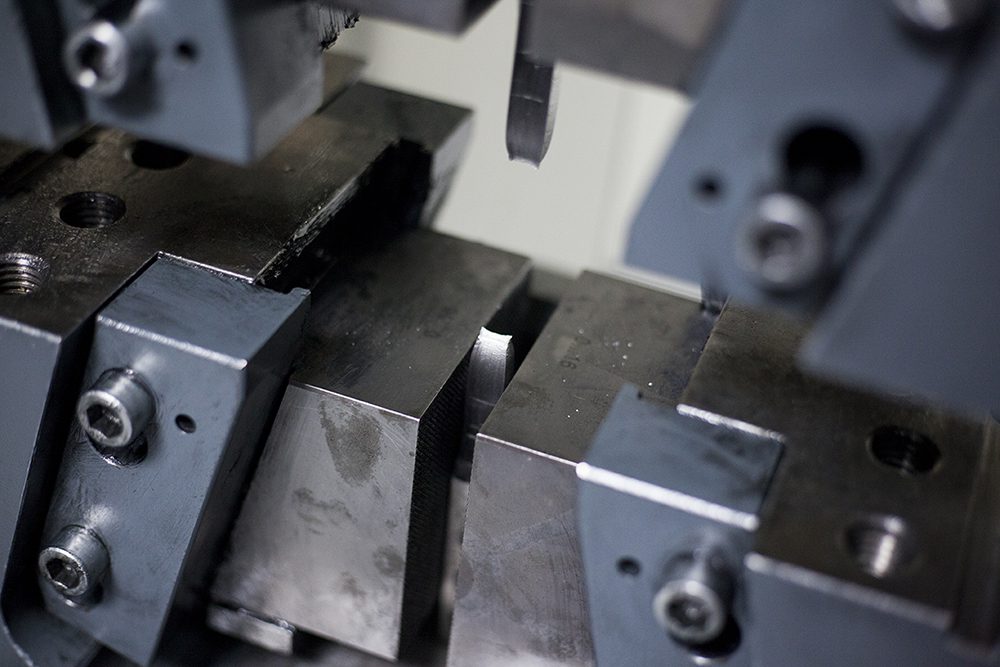

Destructive Testing (DT) Services

Assess the durability and quality of your materials and assets

Destructive testing (DT) assesses the mechanical properties, performance, and safety of your materials, products, and components by subjecting them to stress until they fail. It gives you insights into the durability and reliability of your items. It also ensures they meet industry standards and regulatory requirements, helping you avoid product failures and reduced lifespans.

Destructive Testing services from BES Group

At BES Group, we offer a variety of destructive testing methods to ensure the quality, safety, and reliability of your materials and products. We provide UKAS and NADCAP-accredited tests to help a variety of clients across industries such as aerospace, manufacturing, and healthcare use safe, reliable assets.

Our in-house capabilities provide quick and accurate testing results, which helps minimise downtime and ensure you get the critical data you need.

Below is a summary of our destructive testing services:

Schedule a call to learn more about our Destructive Testing services

Get in touch today Get in touch today Get in touch today

All your Destructive Testing needs in one place

We know sending samples to multiple labs for different testing methods can be frustrating. Not only is it expensive to machine and send multiple samples, but inconsistent results can occur if the labs use samples from different heat-treated batches. At BES Group, we handle all your metals testing in one place to make things easier and more efficient.

Our unique benefits include:

- Comprehensive testing suite: We offer a full suite of tests to thoroughly examine your sample’s properties, structure, and behaviour.

- In-house sample preparation: Our in-house workshop prepares the samples tested in our UKAS-accredited laboratory for consistent and reliable results.

- Efficient sample tracking: Each sample is assigned a unique barcode so we can monitor its progress from arrival to testing completion.

- Rapid turnaround: To minimise downtime and delays, we aim to complete our full suite of destructive tests within three days.

Our services include:

- Full machining and preparation of samples

- Tensile, impact, and hardness testing

- Chemical analysis

- Metallurgical examinations

- Corrosion analysis

- Optional services include salt spray testing, weld assessments, and coating finish testing.

Industries that can benefit from destructive testing services

- Aerospace: Ensures the integrity and performance of aircraft components subject to extreme conditions and stresses.

- Automotive: Validates the durability and safety of vehicle parts, helping manufacturers meet stringent safety standards.

- Construction: Testing the strength and durability of building materials like concrete and steel ensures structures are safe and compliant with regulations.

- Manufacturing: Verifies the properties and performance of manufactured goods, ensuring they meet required specifications and quality standards.

- Healthcare: This department ensures the safety and functionality of medical devices and implants, which is critical for patient health and safety.

- Oil and gas: Assesses the reliability of pipelines, drilling equipment, and other components to prevent failures and ensure safe operations.

Check out our case studies to see how our destructive testing services have benefited some of our clients across these industries.

Benefits of our destructive testing services

Material verification

Confirms that materials meet required specifications and industry standards, ensuring reliability and performance.

Weld quality determination

Assesses the quality and integrity of welded joints, which is critical for structural applications.

Defining asset limitations

Helps identify the limits of materials and components, enabling the creation of plans to reduce failures, accidents, and costs.

Impact resistance assessment

Determining how well materials can withstand impacts and shocks is essential for safety-critical applications.

Failure analysis

Provides detailed insights into how and why materials fail, leading to improved product design and manufacturing processes.

Regulatory compliance

Ensures that products meet industry-specific regulations and standards, which is crucial for market approval and safety certifications.

Destructive Testing FAQs

What is Destructive Testing?

+

Destructive testing subjects a material or component to stress or conditions that cause damage to the point of failure. This type of testing is used to determine the mechanical properties, performance, and durability of materials and structures.

Why is Destructive Testing necessary?

+

Destructive Testing is vital for several reasons:

- Material verification: Confirms that materials meet required specifications and standards.

- Safety assurance: Ensures that components can withstand expected loads and stresses, reducing the risk of failure in critical applications.

- Quality control: Helps identify manufacturing defects and inconsistencies, leading to improved product quality.

- Performance evaluation: Provides detailed information about material properties, such as tensile strength, impact resistance, and fatigue life.

- Regulatory compliance: Ensures products meet industry-specific regulations and standards, which is essential for market approval and safety certifications.

What is the purpose of Destructive Testing?

+

Destructive testing aims to understand how a material will react to extreme stress or loads. Knowing how much stress a material can withstand before complete failure is critical when planning to use that material for a key engineering design, manufacturing process, or product design. Destructive testing is usually carried out according to International Standards or bespoke test methods that align with customer requirements.

What are some standard methods of Destructive Testing?

+

Common destructive testing methods include hardness testing, impact testing, tensile testing, fatigue testing, bend testing, and torsional testing.

Find the right destructive testing method for your premises

What is the difference between Destructive and Non-destructive Testing?

+

Destructive testing of materials (DT) involves examining its properties and performance by subjecting it to stress, strain, or other conditions until it fails. This process provides detailed insights into the material’s strength, durability, and failure modes but results in the destruction of the sample.

On the other hand, non-destructive testing (NDT) evaluates the properties of a material or component without causing any damage, allowing the item to remain in service. NDT methods include ultrasonic, radiographic, and magnetic particle testing, which help detect internal or surface defects without altering the material.

Why do I need Destructive Testing?

+

Destructive testing is crucial in designing, manufacturing, and ensuring product quality across various industries. It provides insight into how much stress a sample can withstand within its intended environment, making this information crucial when deciding whether a particular material or product is suitable.

Learn more about destructive testing

Can Destructive and Non-Destructive Testing be used alongside each other?

+

Destructive and Non-Destructive Testing can be used together to assess materials and components comprehensively. NDT methods can initially screen materials for defects and irregularities, allowing for non-invasive evaluation. Following NDT, DT can be performed on selected samples to get deeper insights into the material’s performance under stress. Both methods allow for a thorough evaluation and ensure the highest safety and quality standards.

What industries or products often require Destructive Testing?

+

Destructive testing is crucial for industries and products where material integrity and performance are critical.

Common industries include:

- Aerospace: To ensure the safety and reliability of aircraft components.

- Automotive: To validate the strength and durability of vehicle parts.

- Construction: To test the quality and safety of building materials like concrete and steel.

- Manufacturing: To verify the properties and performance of manufactured goods.

- Healthcare: To ensure the safety and functionality of medical devices and implants.

- Oil and gas: To assess the reliability of pipelines and drilling equipment.

How would I know what type of Destructive Testing method I need?

+

The material’s standard or specification usually advises the type of destructive test. Our customers then instruct us on what type of destructive test they require. An unknown material must be identified before a destructive test can occur.

Our technologists will conduct chemical analysis tests to identify chemical properties within the material and determine what the material is. We will then provide this information to our customer, and if further testing is required, we will carry out destructive tests to identify the grade of the material. We work with our customers to develop a testing plan to identify the material composition and grade for destructive testing.

Why choose us

Hear what our customers have to say

We care about the journey we take our customers on, but it’s not our word you should be taking, see what our customers think of the service we provided!