Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

Ultrasonic Condition Monitoring

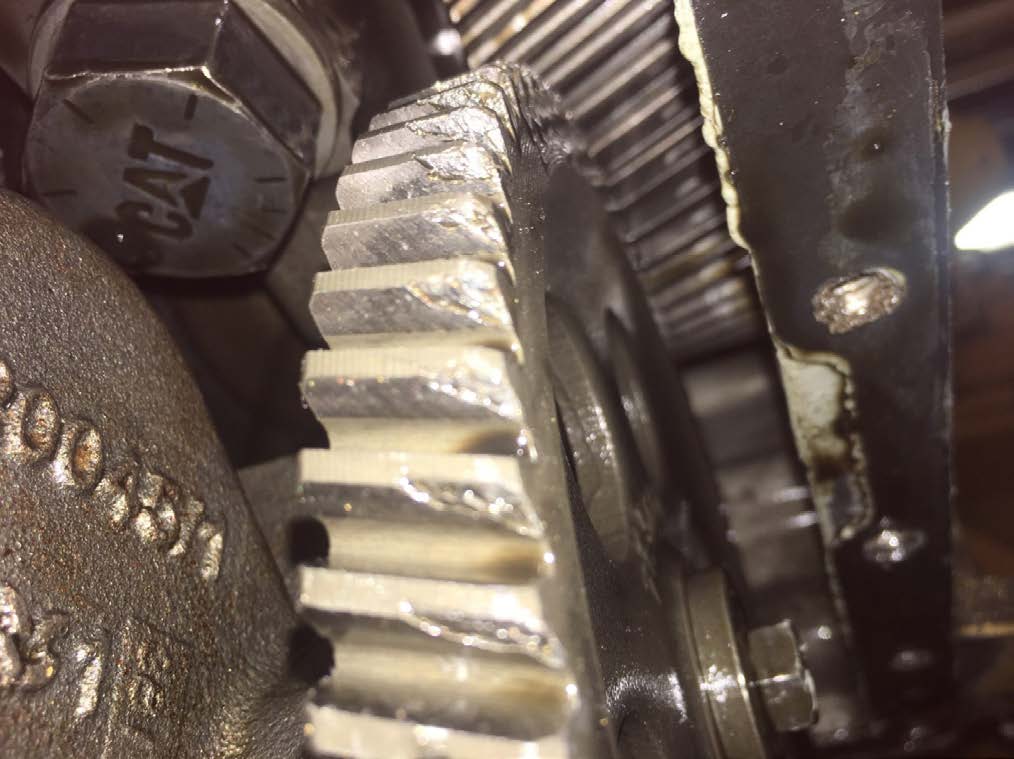

Precisely detecting ultrasonic frequencies associated with mechanical anomalies,

Experience enhanced equipment reliability with BES Group’s Ultrasonic Condition Monitoring. When grappling with issues such as bearing, gear, or rotating machinery defects, our advanced ultrasonic technology becomes your solution.

By precisely detecting ultrasonic frequencies associated with mechanical anomalies, we pinpoint the root causes of problems that may disrupt smooth operations. Whether it’s identifying bearing wear, gear misalignment, or issues within rotating machinery, BES Group offers unparalleled insights.

Our proactive approach allows for targeted interventions, preventing potential breakdowns and optimising the overall performance of your machinery. Trust BES Group to elevate your maintenance strategy with Ultrasonic Condition Monitoring, ensuring operational excellence and minimising the risk of unplanned, costly downtime.

Uncover hidden defects and optimise machinery performance with BES Group's Ultrasonic Condition Monitoring!

Contact us to elevate your machinery's health for peak reliability! Contact us to elevate your machinery's health for peak reliability! Contact us to elevate your machinery's health for peak reliability!

How we'll work with you

From initial planning to results that matter, BES Group will be with you at every step

Planning – We will work with you to identify the assets and frequency of the testing. From this, we will select the appropriate techniques required.

Preparation – The assets may need to be cleaned and access to the assets is required to undertake the inspection.

Inspection – This will be done using Ultrasonic Transducers. These emit high-frequency soundwaves that are reflected from defects. These soundwaves are then analysed to identify the severity, location and size of the defects.

Interpretation – The results will then be analysed by one of our expert analysts who will determine what defects may have been identified during the inspection.

Results – You will be provided with clear and concise reports, along with detailed recommendations of actions that will need to be carried out to rectify any defects.

The benefits of our Ultrasonic Condition Monitoring service

Early detection

Ultrasound provides early warning indications of failure conditions.

Solve problems

Ultrasound will detect lack of lubrication and prevent over lubrication.

Flexible technology

Ultrasound instruments support other technologies.

Why choose us?

The impact of Ultrasonic Condition Monitoring can be

40%

improvement to the reliability of bearings when using Ultrasonic condition monitoring, according to the University of Manchester.

30%

reduction in maintenance costs with the application of Ultrasonic Condition Monitoring, according to the National Physical Laboratory.

20%

extended lifespan of assets, according to the British Institute of Non-Destructive Testing (BINDT) when Ultrasonic Condition Monitoring is implemented.

Hear what our customers have to say

We care about the journey we take our customers on, but it’s not our word you should be taking, see what our customers think of the service we provided!