Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

Condition Monitoring

Detect and diagnose potential problems before they arise with multi-tech surveys and condition monitoring services

At BES Group, we offer a variety of multi-tech surveys and condition monitoring services that can help you detect and diagnose problems early on, before they cause major damage. We also provide cost-effective solutions, including hand-held portable data collectors, wireless sensors, and permanently mounted online monitoring systems.

From Oil Analysis to Ultrasonic Condition Monitoring, Thermography Surveys to Vibration Analysis, our team of industry experienced reliability engineers will tailor our service offering to suit your unique requirements.

Explore our Condition Monitoring services

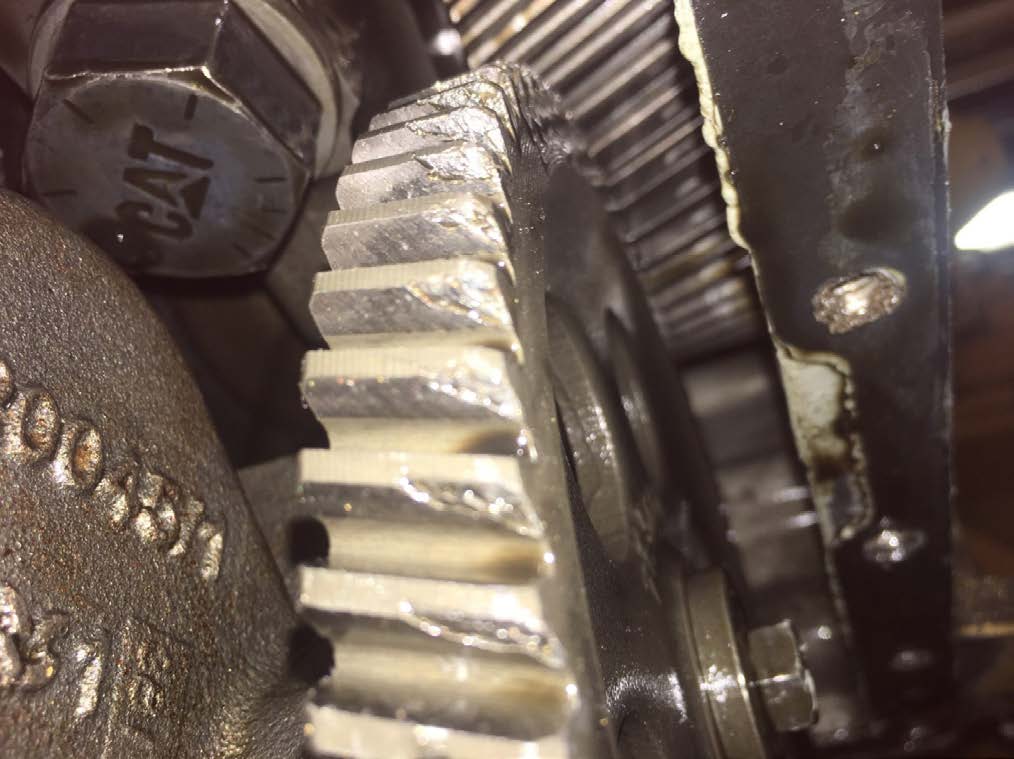

Oil Analysis

Vibration Analysis

Thermographic Surveys

Ultrasonic Condition Monitoring

Video Deflection and ODS

Motor and Current Analysis

Transform your reliability strategy with our cutting-edge Condition Monitoring Services.

Click here to contact a Condition Monitoring expert Click here to contact a Condition Monitoring expert Click here to contact a Condition Monitoring expert

How we'll work with you

Six steps to detecting and diagnosing problems before they arise

- Identify the assets – We will work with you to determine which assets require monitoring through a site scope.

- Choosing the right solution – We offer a variety of services and solutions, and we will determine which is the right type for each asset.

- Installation of solutions – It if is determined through the site scope that you require monitoring solutions to be installed at your site, our engineers will expertly take action to enable data collection.

- Collect data – Depending on the service, data can be collected from the systems installed onsite or by an engineer attending.

- Data analysis – Our Remote Diagnostics Team will analyse the data gathered from your assets and create a full, in-depth report that includes recommendations.

- Reports – You will receive your report through our online reporting platform, Asset Insight 365, allowing you to take any necessary corrective action.

Why choose us?

Industry statistics

70%

reduction in unplanned downtime according to the American Society of Mechanical Engineers when Condition Monitoring is used.

15%

saving on maintenance costs according to the National Association of Manufacturers, for companies that use Condition Monitoring.

20%

extended lifespan of assets for companies using Condition Monitoring according to the University of California, Berkeley.

How our Condition Monitoring services can benefit you!

Improve efficiency

Condition Monitoring can allow you to detect issues that may be affecting the efficiency of your assets.

Prevent unplanned downtime

Condition Monitoring allows you to detect problems before they turn in to critical issues and potentially cause a failure.

Reduce costs

Early detection of problems can help you to make cost-effective repairs, rather than having to replace the entire asset when it fails.

Hear what our customers have to say

We care about the journey we take our customers on, but it’s not our word you should be taking, see what our customers think of the service we provided!

FAQs

When should Condition Monitoring be used?

+

The frequency of Condition Monitoring depends on several factors including the type of asset, the operating environment and the level of risk tolerance.

It is advised that critical assets for safety, production or those that operate in harsh conditions should have condition monitoring performed more frequently and potentially on an hourly or daily basis.

Assets that are deemed important but non critical should be monitored on a weekly or monthly basis.

Other assets can be monitored less frequently on a quarterly or annual basis.

What are the different types of condition monitoring?

+

There are many different types of Condition Monitoring. The most common ones are:

– Vibration Analysis

– Oil Analysis

– Thermography

– Ultrasonic – Testing

– Video Deflection and ODS

– In-Situ Balancing

What can affect the accuracy of Condition Monitoring?

+

The condition of the asset will greatly affect the accuracy of Condition Monitoring. An asset that is in good condition will be easier to monitor than one in poor condition. This is why it is advisable to have condition monitoring solutions set up at the beginning of the asset lifetime.

As there are several types of condition monitoring, each can be used for different reasons and requirements. It’s important that the right solution is chosen to get the best results.

The effectiveness of condition monitoring also depends on the skills and expertise of the person performing it. Many companies believe that they are using condition monitoring solutions to their full potential, but they may not see the full benefits due to a lack of understanding and skill in condition monitoring and interpreting the data gathered.