Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

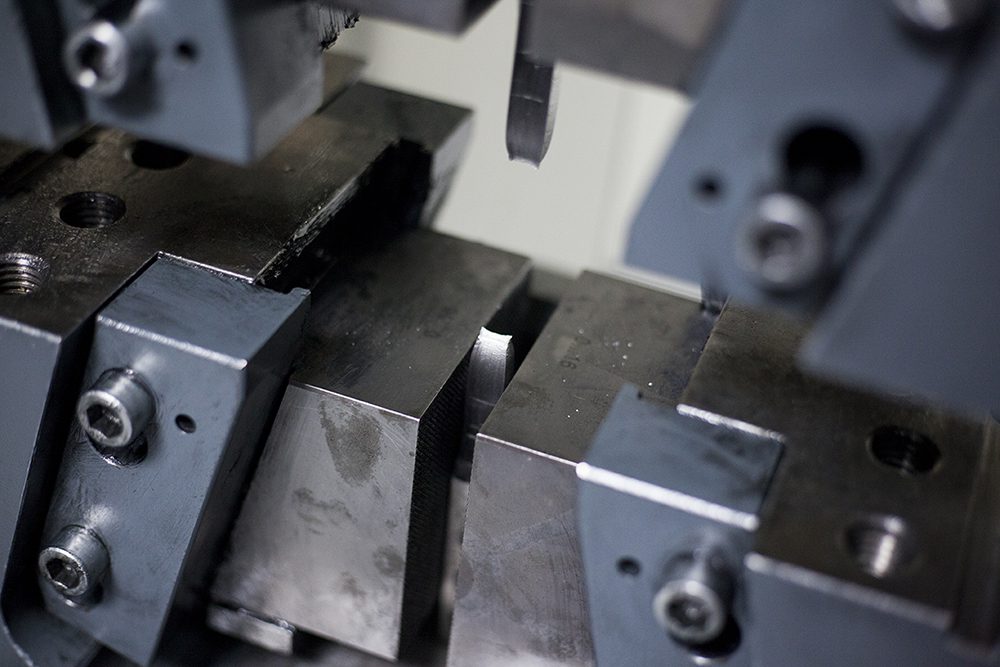

Tensile Testing

Tensile testing is a fundamental method for understanding how materials respond to applied forces, providing crucial insights into their mechanical properties.

At BES Group, we offer comprehensive tensile testing services to meet your material characterisation needs and help you understand more about the performance of your materials. Our tests provide valuable information that can help verify quality standards and ensure quality assurance. By determining the material’s exact tensile strength, we can help prevent potential product failures in the future.

Whether you’re in aerospace, automotive, manufacturing, or any other industry, our testing services can help ensure the quality, reliability, and performance of your materials and products.

We're here to help you understand your product's strength and durability with Tensile Testing.

Get in touch today! Get in touch today! Get in touch today!Our Services

Tensile Testing

Tensile testing is a crucial method for evaluating the mechanical properties of materials. It provides valuable insights into their strength, ductility, and performance under tension.

During a tensile test, a controlled pulling force is applied to a standardized specimen until it breaks. This allows us to measure various parameters such as:

- Yield Strength

- Ultimate Tensile Strength (UTS)

- Elongation

- Youngs Modulus

We can test samples for tensile testing at ambient temperature, with forces from 2kN up to 600kN. We carry out tensile testing to the following standards:

- BS EN ISO 6892-1 Methods A & B

- ASTM E8/8M

- ASTM A370

- BS EN 2002-1

Elevated Temperature Tensile Testing

Our elevated temperature tensile testing services aim to evaluate the mechanical behaviour of materials when exposed to high temperatures. By simulating high-temperature environments, we can assess properties like creep resistance, thermal expansion, and strength retention.

This information is crucial for industries such as aerospace, automotive, power generation, and manufacturing processes that involve high-temperature environments. With our testing, engineers can make informed decisions about material selection and design to ensure the safety, reliability, and performance of components and structures in real-world applications.

We can test samples for elevated temperature tensile testing from ambient up to 600°C, with forces from 2kN up to 100kN. We carry out elevated temperature tensile testing to BS EN ISO 6892-2 Method A ASTM E21.

Schedule a call with our experts

How can Tensile Testing support your business?

Quality Assurance: Tensile testing is vital for ensuring the quality and consistency of materials used in manufacturing processes. By establishing material properties, manufacturers can verify compliance with industry standards and specifications.

Material Selection: Engineers rely on tensile testing data to select appropriate materials for specific applications. Understanding a material’s strength and ductility allows for informed decisions regarding its suitability for a particular environment or load condition.

Product Design and Optimisation: Tensile testing data serves as a crucial input for product design and optimization. By knowing the mechanical behaviour of materials, engineers can design products that meet performance requirements while minimizing the risk of failure.

Research and Development: Tensile testing plays a significant role in materials research and development, enabling scientists and engineers to explore new materials, assess their properties, and innovate in various fields.