Destructive Testing

Mechanical Testing Services

Mechanical testing plays a crucial role in assessing the suitability of materials for their intended applications, ensuring quality control, and aiding research and development efforts.

Explore Mechanical Testing

Interested? Let’s talk.

Send us an enquiry

Who we’ve partnered with...

A snapshot of our Mechanical Testing Services

Mechanical Testing involves evaluating the mechanical properties of materials, such as strength, hardness, ductility, toughness, and elasticity, through various testing methods. It helps assess how materials respond to applied forces and loads. By subjecting materials to various tests such as tensile, hardness, impact, and fatigue testing, manufacturers can ensure their products meet the necessary standards and specifications.

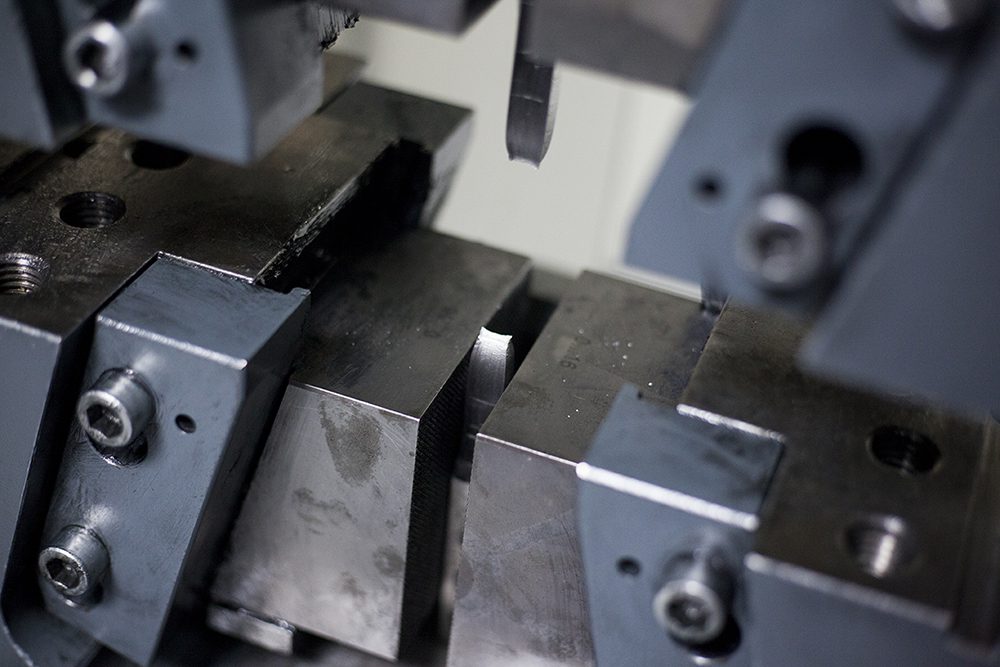

Impact Testing

Impact Testing quantifies the amount of energy absorbed when a sample fractures at high velocity.

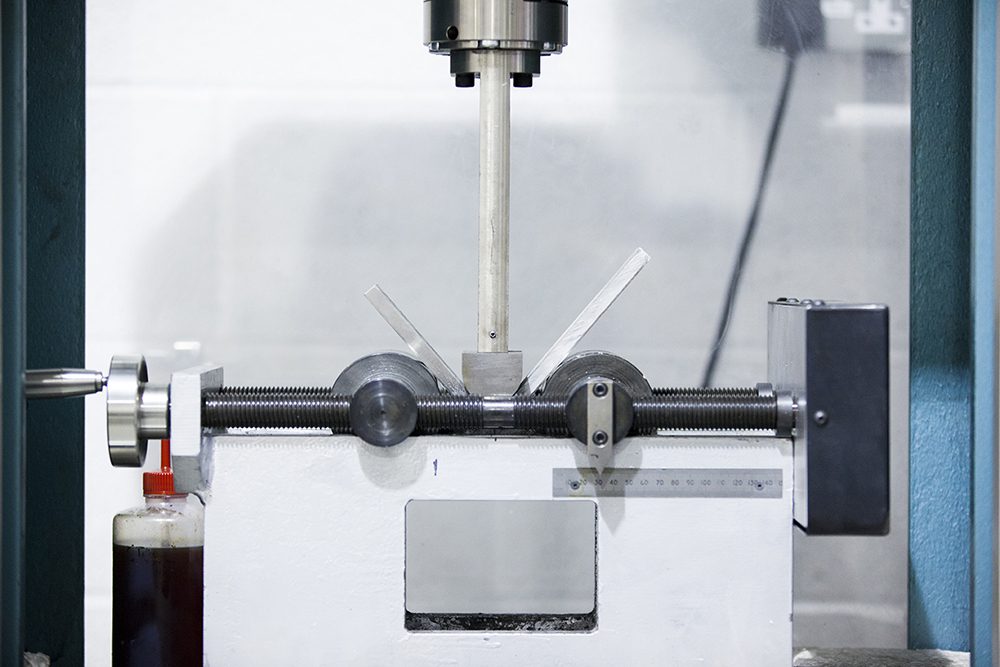

Tensile Testing

Tensile Testing is a fundamental method for understanding how materials respond to applied forces.

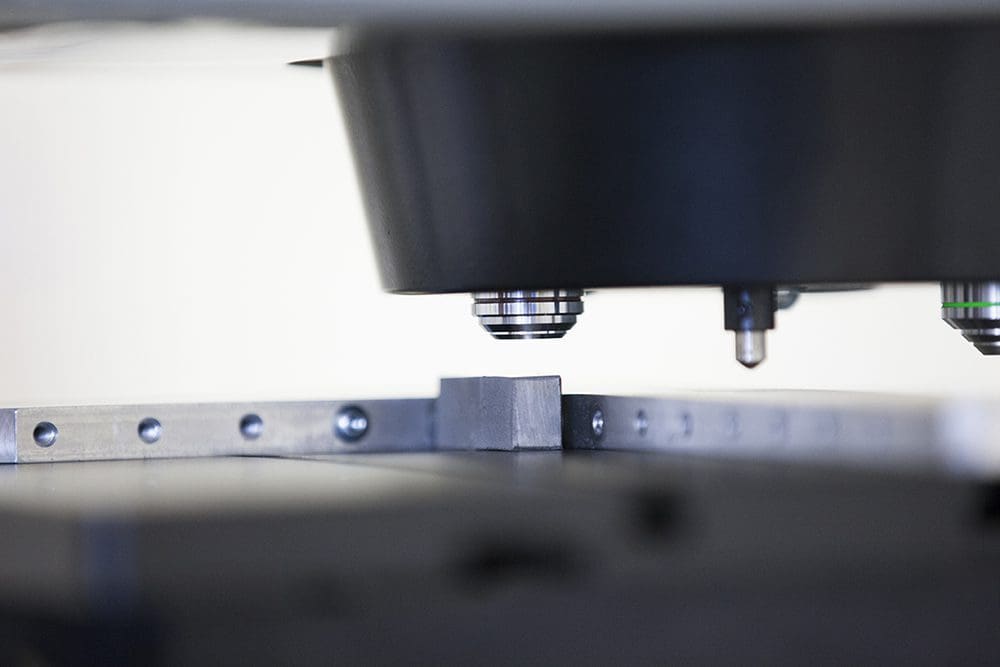

Hardness Testing

Hardness testing on metals is used to evaluate the resistance of a metal to deformation or permanent damage.

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Mechanical Testing at BES Group

Explore all sub-services- What is Mechanical Testing?

- Why is Mechanical Testing important?

- How is Mechanical Testing conducted?

- Key benefits of Mechanical Testing

Mechanical testing is essential for a variety of reasons across different industries, but the most important reason for Mechanical Testing is to ensure quality control.

By subjecting materials to various tests such as tensile, hardness, impact, and fatigue testing, manufacturers can ensure their products meet the necessary standards and specifications.

Mechanical Testing is crucial for research and development purposes. Engineers and scientists rely on mechanical testing to understand the behaviour of materials in different conditions and environments, which is vital for designing and improving new products. By analysing the data gathered from Mechanical Tests, researchers can make informed decisions about material selection, design modifications, and performance enhancements.

Mechanical testing is a valuable tool that contributes to product quality, innovation, and safety in various industries.

Mechanical Testing is crucial for ensuring the quality, reliability, and safety of materials and products. It helps in material selection, design optimisation, quality control, and compliance with industry standards. Mechanical testing plays a key role in Failure Analysis. When a component or structure fails unexpectedly, mechanical testing can help in identifying the root cause of the failure. By conducting tests to determine factors such as material properties, stress concentrations, and environmental effects, engineers can prevent similar failures in the future and enhance the overall reliability of the systems.

Depending on your requirements materials may be subjected to various tests to provide valuable insights and data.

Mechanical Testing is usually carried out using specialised equipment such as:

- Universal testing machines

- Hardness testers

- Impact testers

- Fatigue testing machines

Samples are prepared according to specific standards, and then subjected to controlled conditions to measure their mechanical properties accurately.

Quality Control

Mechanical Testing can help you understand the strength, hardness, and ductility of your material, giving you confidence in the quality and compliance of your product.

Product Development

In the research and development phase, Mechanical Testing aids in the evaluation of new materials or modifications to existing materials. It helps in optimizing designs and ensuring that products meet performance expectations.

Cost Reduction

Carrying out routine mechanical testing will help to identify flaws and defects in materials during early development processes, which can help to prevent costly failures and product recalls.

Material Selection

Mechanical Testing can help to compare the performance and properties of different materials, so that you can choose the most suitable material for product development.

-

What is Mechanical Testing?

Mechanical testing is essential for a variety of reasons across different industries, but the most important reason for Mechanical Testing is to ensure quality control.

By subjecting materials to various tests such as tensile, hardness, impact, and fatigue testing, manufacturers can ensure their products meet the necessary standards and specifications.

Mechanical Testing is crucial for research and development purposes. Engineers and scientists rely on mechanical testing to understand the behaviour of materials in different conditions and environments, which is vital for designing and improving new products. By analysing the data gathered from Mechanical Tests, researchers can make informed decisions about material selection, design modifications, and performance enhancements.

-

Why is Mechanical Testing important?

Mechanical testing is a valuable tool that contributes to product quality, innovation, and safety in various industries.

Mechanical Testing is crucial for ensuring the quality, reliability, and safety of materials and products. It helps in material selection, design optimisation, quality control, and compliance with industry standards. Mechanical testing plays a key role in Failure Analysis. When a component or structure fails unexpectedly, mechanical testing can help in identifying the root cause of the failure. By conducting tests to determine factors such as material properties, stress concentrations, and environmental effects, engineers can prevent similar failures in the future and enhance the overall reliability of the systems.

-

How is Mechanical Testing conducted?

Depending on your requirements materials may be subjected to various tests to provide valuable insights and data.

Mechanical Testing is usually carried out using specialised equipment such as:

- Universal testing machines

- Hardness testers

- Impact testers

- Fatigue testing machines

Samples are prepared according to specific standards, and then subjected to controlled conditions to measure their mechanical properties accurately.

-

Key benefits of Mechanical Testing

Quality Control

Mechanical Testing can help you understand the strength, hardness, and ductility of your material, giving you confidence in the quality and compliance of your product.

Product Development

In the research and development phase, Mechanical Testing aids in the evaluation of new materials or modifications to existing materials. It helps in optimizing designs and ensuring that products meet performance expectations.

Cost Reduction

Carrying out routine mechanical testing will help to identify flaws and defects in materials during early development processes, which can help to prevent costly failures and product recalls.

Material Selection

Mechanical Testing can help to compare the performance and properties of different materials, so that you can choose the most suitable material for product development.

Frequently asked questions

What are some common Mechanical Testing methods?

Common Mechanical Testing methods include tensile testing, hardness testing, impact testing, fatigue testing, and bending tests. Each method assesses specific mechanical properties of materials.

How is Mechanical Testing used in material selection?

Mechanical Testing provides data on a material’s properties and how they behave under certain conditions. This information helps engineers and designers select materials based on factors such as strength, ductility, hardness, and other mechanical characteristics.

How is Mechanical Testing used in quality control?

Mechanical Testing is an integral part of quality control processes to ensure that materials and products meet specified standards. It helps identify defects, variations, or inconsistencies in material properties.

Can Mechanical Testing predict the performance of a product in real-world conditions?

Yes, Mechanical Testing provides valuable data that can be used to predict how materials and products will perform under various loads, stresses, and environmental conditions.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team