Mechanical Testing

Impact Testing Services

Impact Testing plays a crucial role in material science, engineering and product development by providing insights into a material’s response to sudden loads.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Impact Testing?

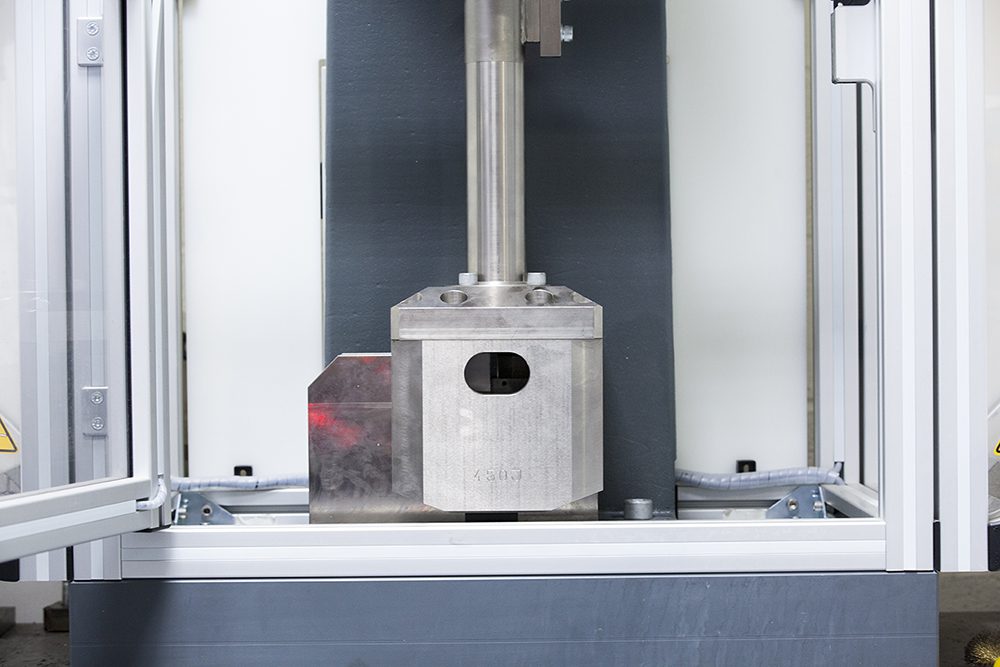

Impact Testing replicates sudden loading or impact events that materials may encounter in real-life situations.

Impact testing quantifies the amount of energy absorbed when a sample fractures at high velocity. By subjecting materials to dynamic loading conditions, impact testing offers valuable insights into their behaviour, while other tests concentrate on static or quasi-static loading.

Whether it involves evaluating the strength of metals in structural components or the durability of polymers in consumer products, impact testing offers valuable insights into a material’s resilience, toughness, and overall performance. It serves as a quality control measure to determine the toughness of different materials.

Who we’ve partnered with...

Key benefits of Impact Testing

Material strength assessment

Impact testing can help to determine the ability of a material to withstand sudden loading or shock. It provides information on the material's resistance to fracture or deformation under stressful conditions.

Material selection

Engineers and designers use impact test results to choose materials that will withstand specific service conditions, such as those encountered in structural components or machinery subjected to dynamic forces.

Quality control

Industries use Impact Testing as a quality control measure to ensure that materials meet specified standards and requirements. It helps identify any defects or inconsistencies in the manufacturing process that could compromise the material's performance.

Structural Integrity Assessment

For structures and components subject to impact or dynamic loading, impact testing is essential to assess their ability to withstand these conditions without catastrophic failure.

Let's talk about Impact Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

What can Impact Testing be used for?

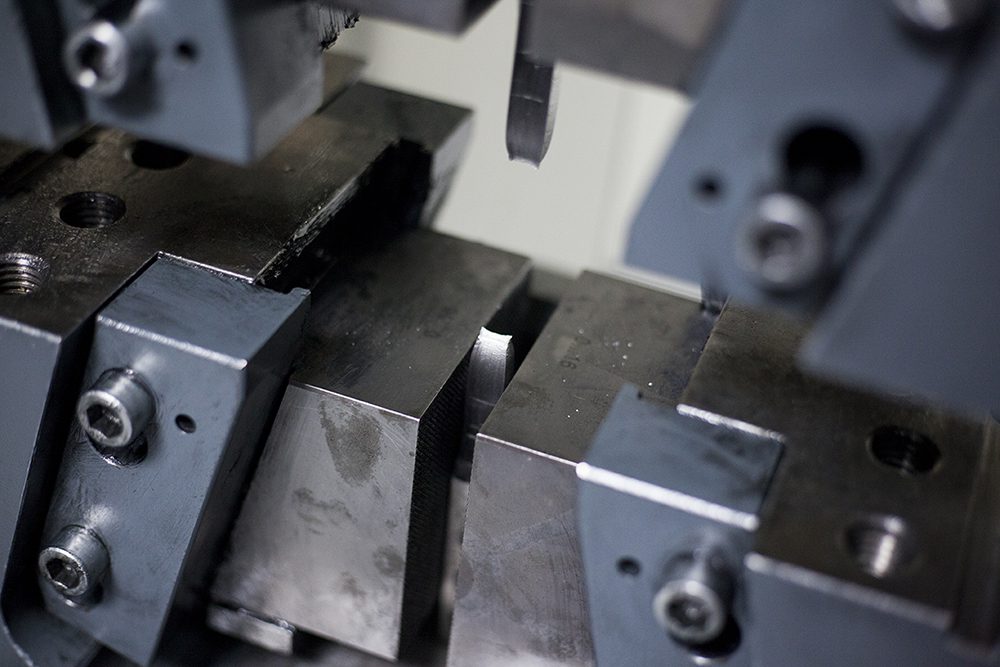

A wide range of metals can be impact tested to assess their toughness, resilience, and suitability for various applications. Impact Testing may involve a Charpy or Izod test.

Charpy tests are generally preferred for brittle materials, and are prevalent in the metallurgical industry for metals and alloys. Izod tests are more suited for ductile materials and finds extensive use in evaluating the impact resistance of non-metallic materials.

While both tests are widely used in Impact Testing, there are some differences in their applications and interpretations.

Understanding the differences between these two Impact Testing methods can help ensure accurate and reliable evaluation of material toughness for various applications.

Impact Testing on metals

By conducting Impact Tests, we can ensure that metals perform reliably and meet the required standards in various service environments.

Some of the commonly tested metals include:

Steel

Different types of steel, including carbon steel, alloy steel, and stainless steel, undergo Impact Testing to assess their toughness and fracture behaviour. Widely used in structural components, machinery, and construction materials.

Aluminium alloys

Impact Testing plays a crucial role in evaluating the strength and durability of aluminium alloys when exposed to sudden loading conditions and impacts. Used in industries like aerospace, automotive, and structural applications.

Copper

This includes copper alloys such as brass and bronze. Utilised within electrical components, plumbing fixtures, and architectural elements. Impact testing helps assess the ductility and toughness of copper-based materials.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What's the difference between Charpy and Izod Impact Testing?

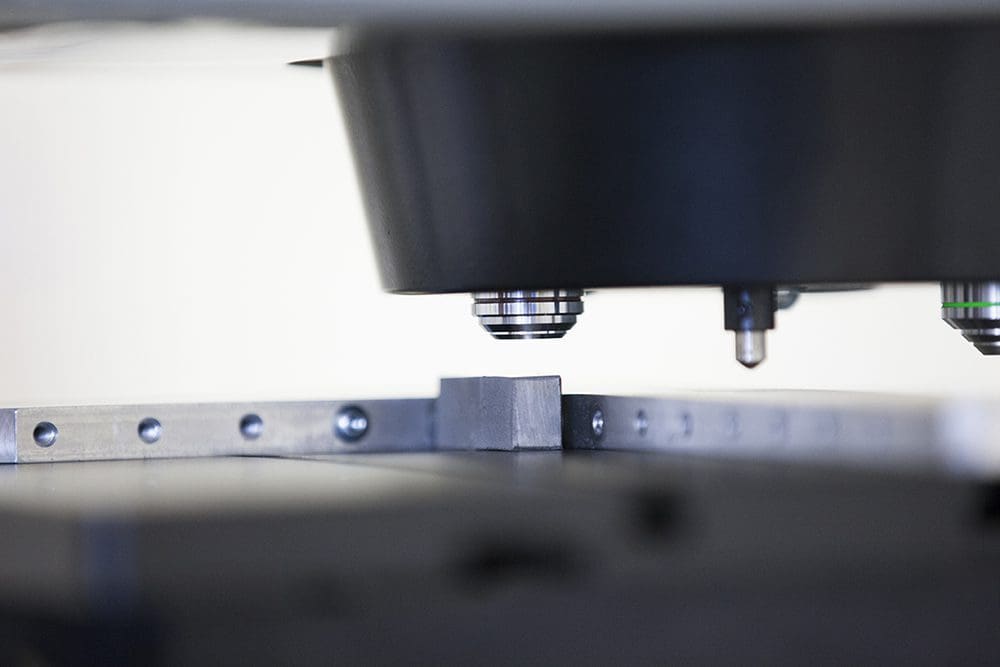

Impact testing, whether through the Charpy or Izod method, is essential for evaluating the toughness and resilience of materials under sudden loading conditions. While both tests assess the impact strength of materials, they differ in their test setups.

- Charpy testing: the specimen is placed horizontally into the test machine and supported at both ends.

- Impact testing: the specimen is placed vertically into the test machine and clamped at one end.

When a pendulum strikes the notched part of the specimen, it breaks and the energy absorbed by the specimen is measured. This energy absorption indicates the material’s resistance to impact loading.

What other types of metals can Impact Testing be applied to?

- Titanium alloys have excellent strength-to-weight ratio and corrosion resistance and are commonly used in aerospace, medical, and marine industries. Impact testing is essential for evaluating the impact toughness of titanium alloys, particularly in critical components subjected to dynamic loading conditions.

- Nickel-based alloys, such as Inconel and Monel, find wide usage in high-temperature and corrosive environments, such as chemical processing, aerospace, and marine applications. Impact testing helps assess the fracture resistance and durability of nickel-based alloys under extreme conditions.

- Various types of cast iron may undergo impact testing to evaluate their fracture behaviour and shock resistance. Impact testing is particularly important for assessing the suitability of cast iron components in machinery and structural applications.

- High-strength alloys, such as maraging steel, superalloys, and advanced composites, are frequently subjected to impact testing to evaluate their performance and durability.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team