What is Young’s Modulus?

Young’s Modulus, also known as Elastic Modulus, measures the stiffness of materials and its ability to resist deformation when subjected to tensile stress. It quantifies how much a material will stretch or compress under an applied force.

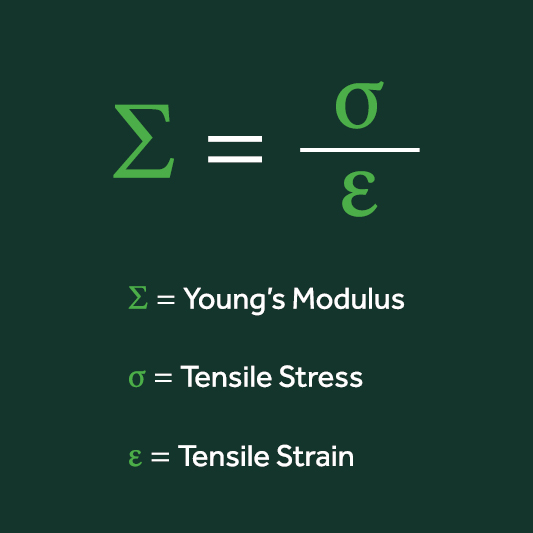

How to Calculate Young’s Modulus?

Mathematically, the definition of Young’s Modulus is the ratio of the stress (force per unit area) applied to the material and the resulting strain (deformation) in the linear elastic region of the material. For metals, Young’s Modulus is typically expressed in gigapascals (GPa) as their stiffness values are very high.

For example:

- Magnesium alloy Young’s Modulus is around 0.01 GPa which means this is a flexible and elastic metal, as it is very elastic and flexible.

- Diamond Young’s Modulus is around 1050-1220 GPa, making it the hardest natural material known.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team