Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

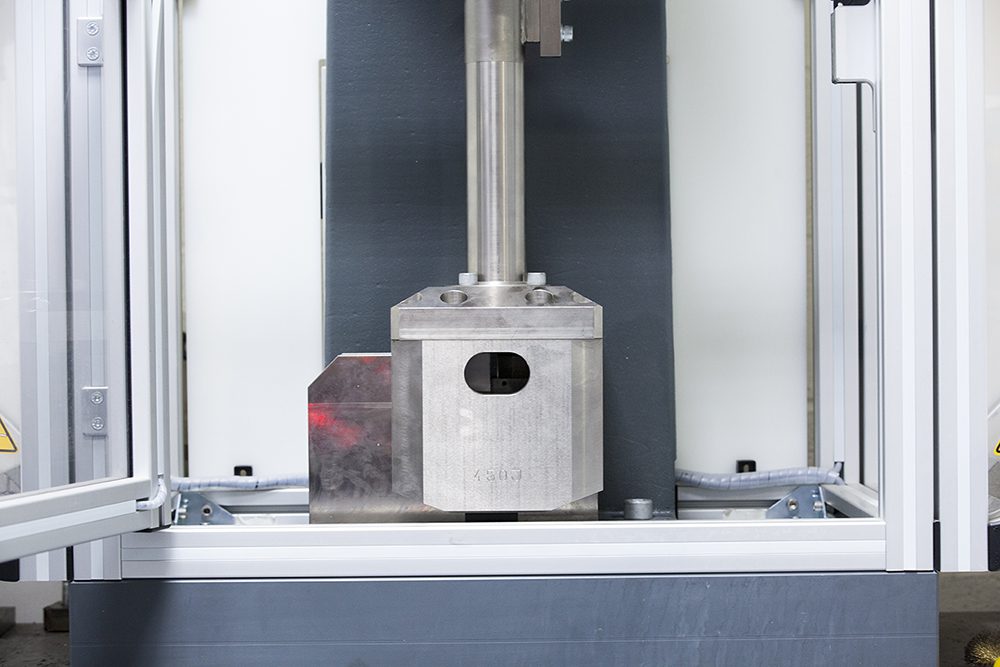

Impact Testing

Understand how your materials behave to sudden loading conditions with impact testing

Impact testing plays a crucial role in material science, engineering and product development by providing insights into a material’s response to sudden loads. By measuring a material’s resistance to impact and facture behaviour, our tests can support you in designing safer, more reliable products. Whether it’s ensuring the structural integrity of construction, or the safety of automotive components, impact testing helps to build a safer and more resilient world.

Are your materials strong enough? Find out with our Impact Testing services!

Get in touch today! Get in touch today! Get in touch today!Our Impact Tests

Charpy Impact Test

The Charpy Impact test is a high strain-rate method used to assess the impact toughness of metals and alloys.

It involves striking a notched specimen with a pendulum and measuring the energy absorbed during fracture. This is held by a set of support anvils and located using verified tongs, in a central horizontal positive to receive a controlled weight pendulum from a set height.

This test is commonly used to assess metals that are susceptible to sudden shock, and is especially useful in industries such as construction and automotive to evaluate the strength of materials used in machinery and equipment. It helps determine if steels, stainless steel and related alloys meet the specified mechanical properties and identify any production issues that need to be addressed.

We carry out Charpy Impact testing to the following standards (-196°C and -120°C to ambient) BS EN ISO 148-1: ASTM A370, ASTM E23.

Send us your Impact Testing requirementsIzod Impact Test

Similar to the Charpy Impact test, the Izod Impact test is a method used to measure the energy absorbed by a notched specimen when it is struck by a pendulum. It is commonly employed to test the impact strength of materials, especially plastics and polymers.

During the Izod test, the sample is impacted in a vertical orientation at room temperature. A pivoting arm is raised to a specific height and then released, causing the arm to swing down and strike the notched sample, resulting in its breakage.

This test is highly valuable in determining the relative toughness or impact toughness of materials, as it is both fast and cost-effective, making it ideal for quality control purposes.

We carry out Izod Impact testing to BS 131:Part 1.

Send us your Impact Testing requirements

Impact Testing on Metals

A wide range of metals can be impact tested to assess their toughness, resilience, and suitability for various applications. Some of the commonly impact-tested metals include:

- Steel is subjected to extensive impact testing because it is widely used in structural components, machinery, and construction materials. Different types of steel, including carbon steel, alloy steel, and stainless steel, undergo impact testing to assess their toughness and fracture behaviour.

- Aluminium alloys are commonly employed in industries like aerospace, automotive, and structural applications. Impact testing plays a crucial role in evaluating the strength and durability of aluminium alloys when exposed to sudden loading conditions and impacts. By conducting impact tests, we can ensure that these alloys perform reliably and meet the required standards in various service environments.

- Copper and its alloys, such as brass and bronze, may undergo impact testing to evaluate their suitability for various applications, including electrical components, plumbing fixtures, and architectural elements. Impact testing helps assess the ductility and toughness of copper-based materials.

- Titanium alloys are commonly used in aerospace, medical, and marine applications due to their excellent strength-to-weight ratio and corrosion resistance. Impact testing is essential for evaluating the impact toughness of titanium alloys, particularly in critical components subjected to dynamic loading conditions.

- Nickel-based alloys, such as Inconel and Monel, find wide usage in high-temperature and corrosive environments, such as chemical processing, aerospace, and marine applications. Impact testing helps assess the fracture resistance and durability of nickel-based alloys under extreme conditions.

- Various types of cast iron may undergo impact testing to evaluate their fracture behaviour and shock resistance. Impact testing is particularly important for assessing the suitability of cast iron components in machinery and structural applications.

- High-strength alloys, such as maraging steel, superalloys, and advanced composites, are frequently subjected to impact testing to evaluate their performance and durability.

Benefits of Impact Testing

Material strength Assessment

Impact testing can help to determine the ability of a material to withstand sudden loading or shock. It provides information on the material's resistance to fracture or deformation under stressful conditions.

Material Selection

Engineers and designers use impact test results to choose materials that will withstand specific service conditions, such as those encountered in structural components or machinery subjected to dynamic forces.

Quality Control

Industries use impact testing as a quality control measure to ensure that materials meet specified standards and requirements. It helps identify any defects or inconsistencies in the manufacturing process that could compromise the material's performance.

Structural Integrity Assessment

For structures and components subject to impact or dynamic loading, impact testing is essential to assess their ability to withstand these conditions without catastrophic failure.