Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

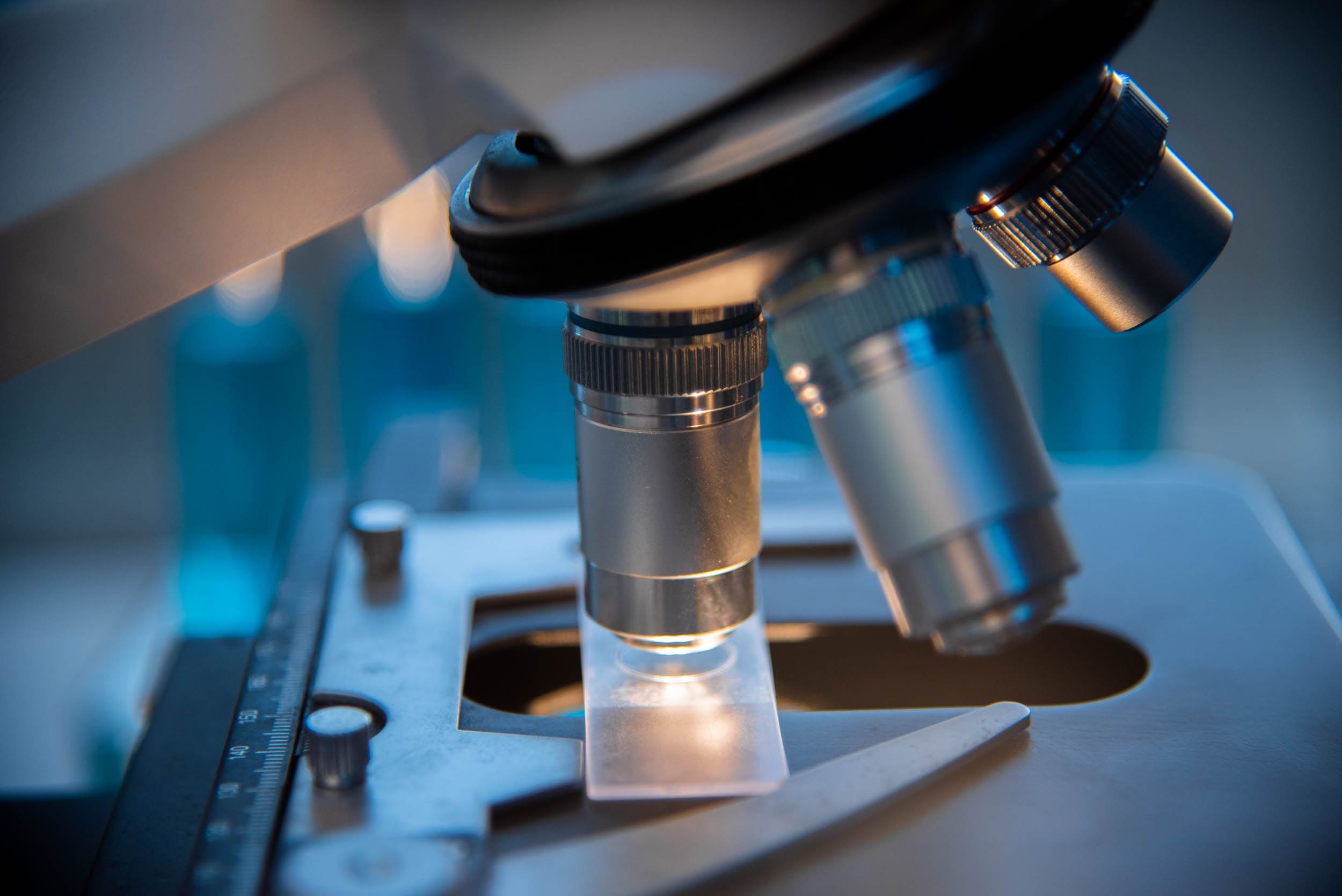

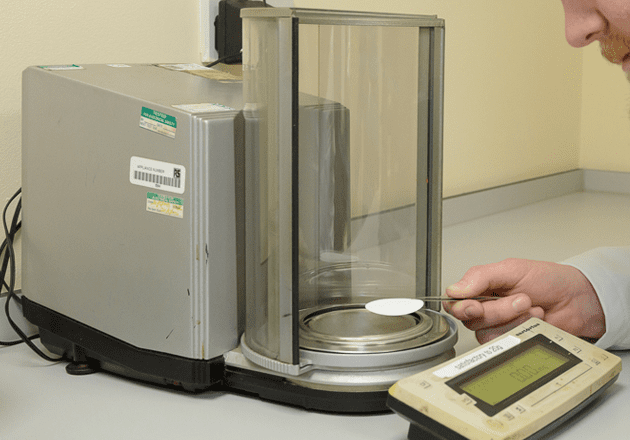

Cleanliness Testing

In industries like automotive and aerospace, precision and meticulousness are absolutely crucial. Ensuring the cleanliness and removal of contaminants from components is vital to guarantee their reliability.

Cleanliness testing is a critical aspect of quality control in various industries, ensuring that components, surfaces, and systems meet stringent cleanliness standards. Our comprehensive cleanliness testing services are designed to guarantee the highest level of quality, reliability, and compliance with industry regulations.

In the automotive and aerospace sectors, and many others, precision and attention to detail are paramount. Contamination removal and cleanliness verification of components are really important in ensuring the reliability of components. This helps reduce the likelihood of costly field failures and caters for the demand for longer warranty periods.

We offer a cleanliness testing service from our designated Nadcap accredited facility, offering a fully contained cleanliness verification process and minimising risk of contamination.

The activities identified with * are not UKAS accredited.

Let us worry about the small stuff

Our dedicated Nadcap accredited cleanliness testing laboratory means we can verify component cleanliness after manufacturing processes, where detection of levels of particulate contamination is seen as critical. Our tests cover specifications for suppliers such as Meggitt Control systems, where qualitative and quantitative detection of particulate contamination is crucial in ensuring parts are free from materials which may be harmful to the functionality of the end product.

The cleanliness laboratory is a contained, controlled environment in which we are able to carry out metal cleanliness testing and test components efficiently and effectively in accordance with Inspection Standards.