Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

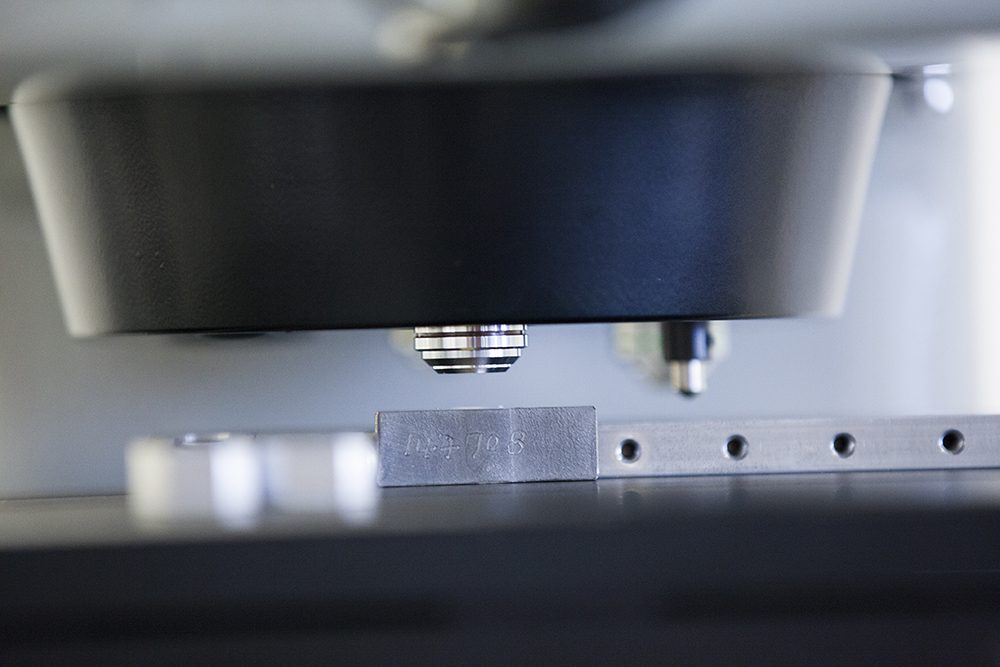

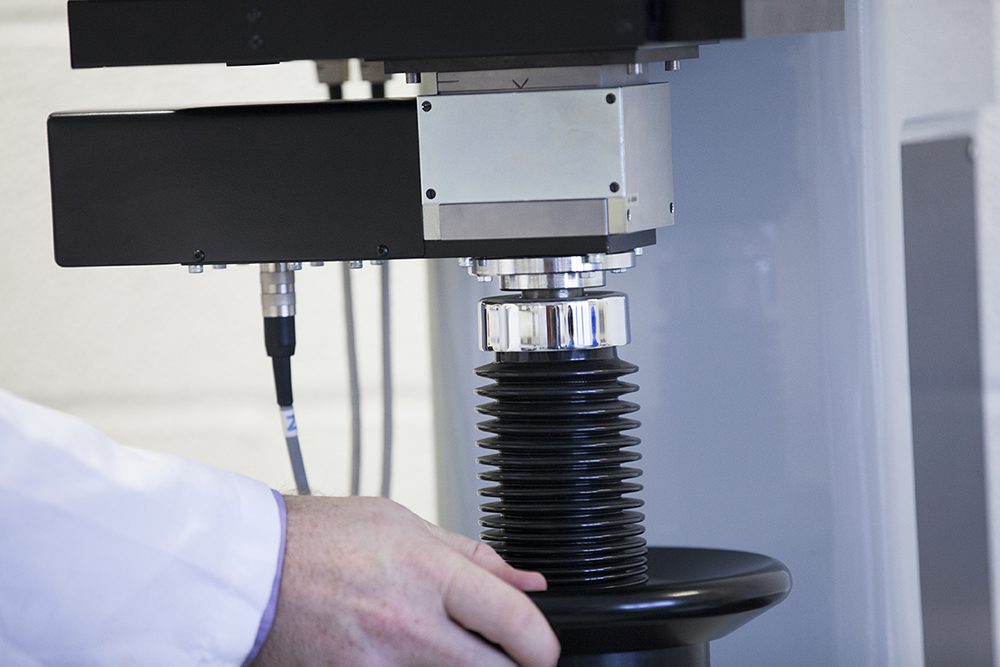

Vickers Hardness Testing

The Vickers hardness test is known for its ability to provide precise and accurate hardness measurements, making it suitable for a wide range of materials, including metals, ceramics, and some polymers.

Vickers hardness testing is particularly useful for softer materials and thin sections. The test is widely used in quality control, material research, and engineering applications to assess a material’s resistance to deformation and wear. The Vickers hardness scale covers a broad range, making it applicable to various materials with different hardness levels.

Vickers Testing Specifications

- BS EN ISO 6507-1:2018 (HV1, HV5, HV10)

- ASTM E92-17 (HV1, HV5, HV10)

- Low force Vickers Hardness tests (HV0.3, 0.5, and 1)

Find out how we can help with your hardness testing requirements

Get in touch today! Get in touch today! Get in touch today!

Common uses for Vickers Hardness Testing

The Vickers hardness test provides precise and reliable measurements, making it a valuable tool in industries such as manufacturing, aerospace, automotive, and materials science. Its ability to cover a broad hardness range and accommodate various materials makes it a popular choice in different applications.

- Metals and Alloys: Vickers hardness testing is widely employed in the assessment of the hardness of metals and alloys. It is applicable to a broad range of materials, including ferrous and non-ferrous metals.

- Quality Control: The Vickers hardness test is commonly used in quality control processes to ensure that materials meet specified hardness requirements. It helps manufacturers maintain consistency and adherence to standards.

- Material Research and Development: Researchers and material scientists use Vickers hardness testing to study the mechanical properties of new materials, alloys, and composites. This helps in understanding how materials respond to various loads and conditions.

- Thin Sections and Small Components: Vickers hardness testing is particularly useful for evaluating the hardness of thin sections and small components. Its ability to use lighter loads makes it suitable for delicate materials and small sample sizes.

- Coatings and Surface Treatments: The method is applied to assess the hardness of coatings and surface treatments, providing insights into the effectiveness of processes like heat treatment, plating, or deposition.

- Hard Materials: Vickers hardness testing is suitable for assessing the hardness of hard metals and materials with high hardness values. It is capable of producing accurate results for a wide range of hardness levels.

- Comparative Hardness Testing: When a standardized and widely applicable hardness testing method is required, Vickers hardness testing is often chosen due to its versatility and suitability for a diverse range of materials.