Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

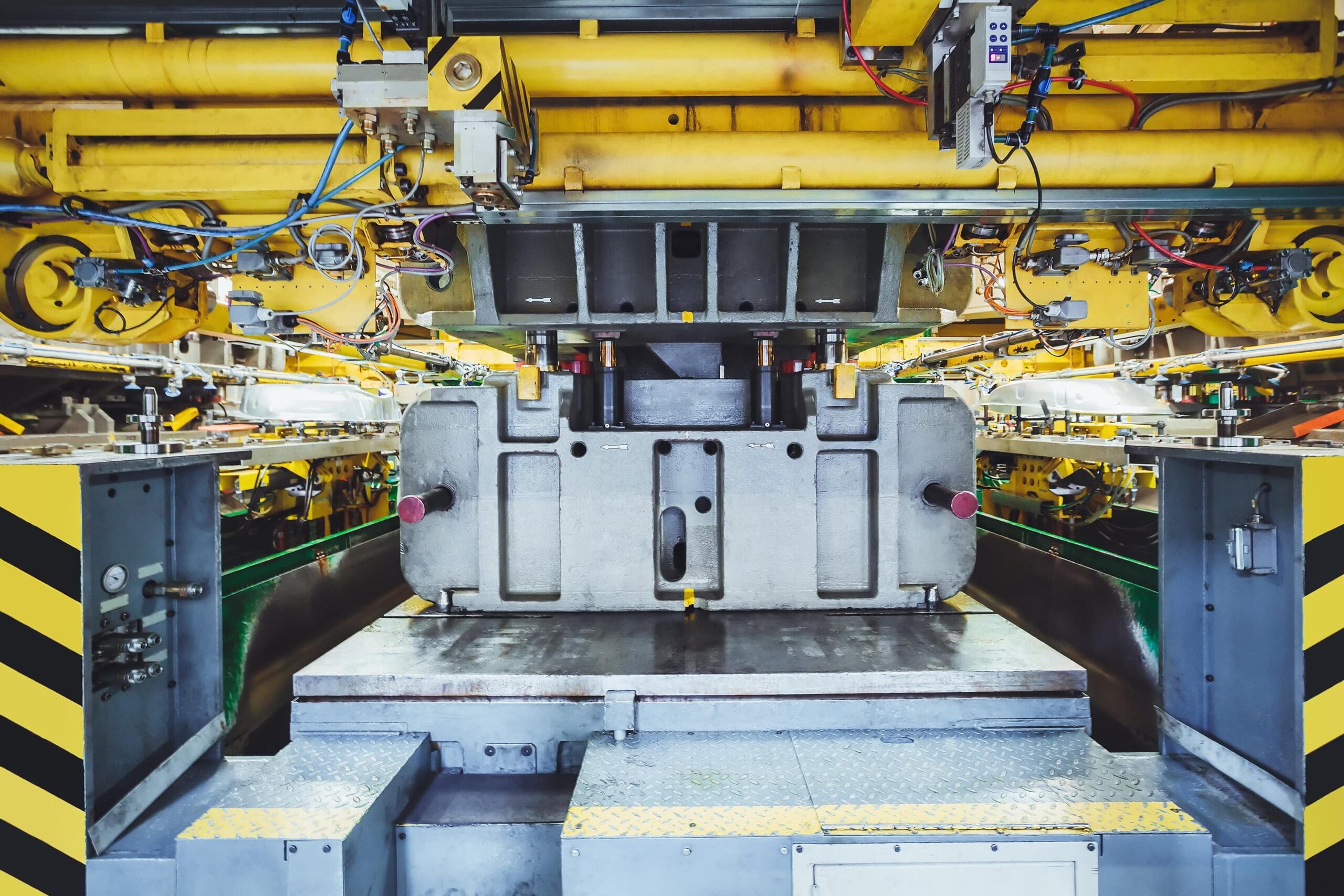

Provision and Use of Work Equipment Regulations (PUWER)

As an employer or employee, it is important that you are aware of any regulations that may apply to your workplace.

The Provision and Use of Work Equipment Regulations, also known as PUWER, are a set of regulations used in the United Kingdom to make sure work equipment is being used safely. They’re designed to protect the health and safety of employees, as well as anyone who may be affected by using work equipment, including customers.

Helping our customers to achieve compliance

PUWER applies to a wide range of equipment from all industries in the UK, including anything from machinery and tools to vehicles, appliances, and systems used in the workplace.

These regulations place duties on employers, employees, and the self-employed who work with or around such equipment to take the necessary precautions to keep themselves, and their team, safe. Some of these duties include:

- Conducting risk assessments to identify potential hazards

- Making sure equipment is properly maintained and inspected

- Providing adequate training and information to employees

- Implementing measures to control risks

- Also, as part of this, employees are expected to cooperate with their employers, follow safe work practices, and report any equipment defects or hazards that they may find while working.

Ensure complete PUWER compliance and protect your workforce and property with our specialised Equipment Inspections

Schedule a call with an inspection expert Schedule a call with an inspection expert Schedule a call with an inspection expert

How we work with you

Our process at BES Group for an inspection under the Provision and Use of Work Equipment Regulations (PUWER) involves:

- Identifying the work equipment that needs to be inspected. This step will depend on the specific hazards associated with the work equipment and the activities that are carried out using it.

- Creating the plan of inspection. This plan will take into account the scope, the inspection methods, and how frequently the equipment needs to be inspected.

- Then, our team of expert engineer surveyors will carry out the inspection in a systematic manner, focusing on hazardous areas in particular.

- After each inspection, our engineers will comprise a detailed report of our findings and recommendations in a way that’s simple and clear to understand.

- Following this, we’ll work with you to decide on an action plan for rectifying any hazards or faulty equipment found during the inspection. Whether that’s replacing work equipment or implementing new safety measures, no matter what, you’ll be kept up to date at each stage of the process.

With our stringent equipment safety inspections, we can help to ensure that your work equipment is safe to use, your workers are protected from harm, and your business is legally compliant.

FAQs

What are the key provisions of PUWER?

+

The Provision and Use of Work Equipment Regulations includes several key provisions to ensure the safe use of work equipment in the workplace. Here are the primary provisions of PUWER:

Risk Assessment: PUWER requires employers to conduct a comprehensive risk assessment of work equipment to identify potential hazards, assess risk and determine appropriate control measures to mitigate risks.

Safe Equipment Selection and Design: Employers must ensure that work equipment is suitable for its intended use, considering factors like the nature of the work, foreseeable hazards, and the capabilities of the users.

Maintenance, Inspection, and Repair: PUWER mandates that work equipment is maintained in a safe working condition with regular inspections, maintenance procedures, and repair processes.

Employee Training and Competence: Employers are responsible for providing adequate training and instruction to employees who use or operate work equipment. Training should cover safe working practices, equipment operation, emergency procedures, and any specific risks associated with the equipment.

Information, Instruction, and Supervision: Employers must provide employees with clear information and instructions regarding the safe use of work equipment. This includes any specific operating procedures, safety precautions, and potential risks.

Emergency Procedures and Safety Measures: PUWER requires employers to establish and communicate emergency procedures, such as evacuation plans, equipment shutdown protocols, and first aid arrangements, and to supply suitable personal protective equipment (PPE).

Control of Substances Hazardous to Health (COSHH): When work equipment involves the use of hazardous substances, employers must comply with the Control of Substances Hazardous to Health Regulations (COSHH), which includes conducting risk assessments, implementing control measures, and providing suitable PPE and training.

Specific Requirements for Mobile Work Equipment, Lifting Equipment, and Power Presses: PUWER also includes additional provisions specific to certain types of work equipment, such as mobile work equipment (e.g., forklift trucks), lifting equipment (e.g., cranes, hoists), and power presses. These requirements outline specific safety measures and inspections for these types of equipment.

It’s important for employers and employees to make sure they’re aware of the detailed provisions of PUWER that apply to their workplace and equipment, to make sure they have a safe working environment and are compliant with the relevant regulations.

What work equipment is covered by PUWER?

+

Machinery

Storage Racking

Roller Shutter Doors

Appliances

Apparatus

Tools

Installations

Personal protective equipment (PPE)

What are the requirements for PUWER inspections?

+

The inspections must be carried out by a competent person. A competent person is someone who has the necessary knowledge, skills, and experience to carry out the inspections safely and effectively.

The inspections must be recorded. The records should include the date of the inspection, the findings of the inspection, and any action taken as a result of the inspection.

The inspections must be carried out at suitable intervals. The frequency of inspections will depend on the type of equipment and the level of risk associated with it.

The inspections must be thorough. The inspections should cover all aspects of the work equipment, including the condition of the equipment, the safety features, and the operating instructions.

How often should work equipment be inspected?

+

The frequency of work equipment inspections depends on the type of equipment and the level of risk associated with it. The following are some general guidelines for how often work equipment should be inspected:

High-risk equipment: This includes equipment that is used in hazardous environments or that has the potential to cause serious injury or death if it is not properly maintained. This type of equipment should be inspected at least every 6 months.

Medium-risk equipment: This includes equipment that is used in less hazardous environments or that has the potential to cause minor injury or damage if it is not properly maintained. This type of equipment should be inspected at least annually.

Low-risk equipment: This includes equipment that is used in safe environments or that has the potential to cause only minor inconvenience if it is not properly maintained. This type of equipment should be inspected at least every 2 years.

Who can carry out PUWER inspections?

+

A competent person can carry out PUWER inspections. A competent person is someone who has the necessary knowledge, skills, and experience to carry out equipment safety inspections safely and effectively.

Key benefits of PUWER compliance

Avoid penalties

by following the regulations and implementing best practices, employers can ensure the safety of their employees, reduce the risk of accidents, and avoid legal penalties.

Correct hazards

Inspections under the Provision and Use of Work Equipment regulation can help to identify and correct any hazards associated with work equipment, such as loose guards, sharp edges, or missing safety features.

Equipment maintenance

Equipment safety inspections under PUWER help to keep equipment in a safe condition, by checking for wear and tear and replacing any damaged parts.

Improve staff awareness

PUWER inspections can help to raise employee awareness of the importance of safety, as employees can learn about the hazards associated with work equipment and how to operate them safely.

Protect your business

By achieving PUWER compliance, businesses can help to protect themselves from liability in the event of an accident, by being able to prove that they have taken steps to reduce the risk of accidents.

Did you know?

37

fatal injuries involving work equipment in the UK took place in 2021/22, according to the HSE

£1.5 million

was charged in fines to a customer by the HSE in 2021/22 for a breach of health and safety regulations.

1,332

enforcement notices were issued to companies for breaches of health and safety regulations by the HSE in 2021/22.

Why choose us

Hear what our customers have to say

We care about the journey we take our customers on, but it’s not our word you should be taking, see what our customers think of the service we provided!