Destructive Testing

Metallography & Metal Testing

At BES Group, we carry out a wide range of Metallography Testing Services to help you understand the microstructure, characteristics, and properties of your metals.

Explore our process

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with...

A Snapshot of our Metallography Services

Metallography is the study of the structure and composition of metals and alloys, crucial for understanding their microscopic features, chemical properties, and mechanical behaviour. Through detailed analysis, Metallography helps evaluate the effectiveness of heat treatments, predict material performance, and ensure quality control. It plays a key role in product development and enhancing metal longevity for various industrial applications.

Cleanliness Testing

Cleanliness Testing ensures metals are contamination-free in compliance with NADCAP standards.

Corrosion Testing

Corrosion Testing assesses metal resistance, predicting longevity and ensuring durability in harsh conditions.

Failure Investigations

Failure Investigations identify root causes of failures, offering insights to improve design processes.

Fracture Analysis

Fracture Analysis identifies causes of material fractures, preventing failures, enhancing reliability, and aids quality.

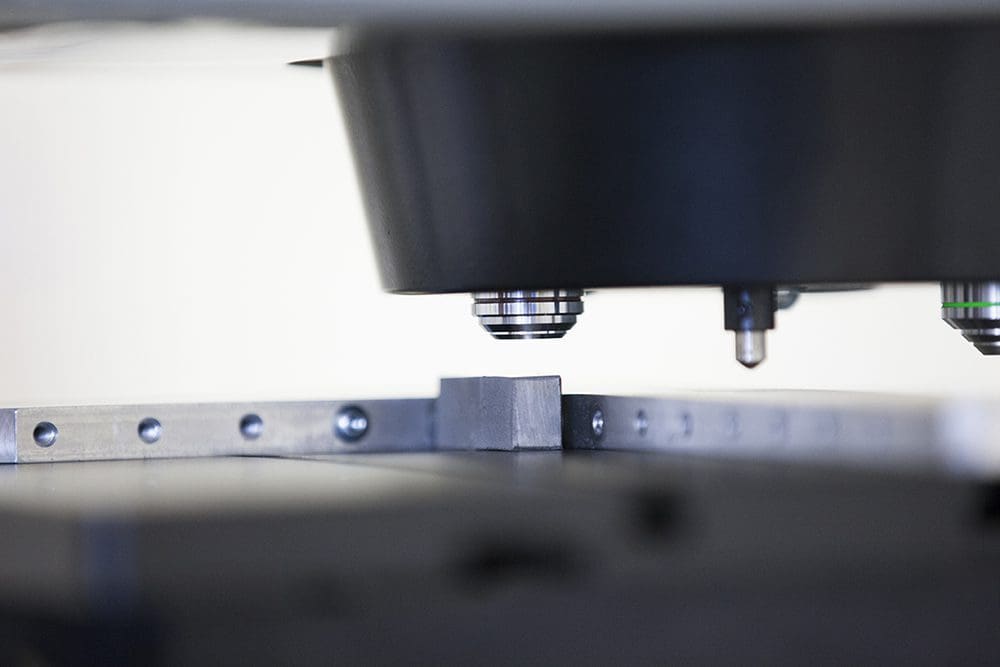

SEM & EDX Analysis

SEM and EDX provide high-resolution imaging and detailed elemental analysis for precise material characterisation.

Weld Testing

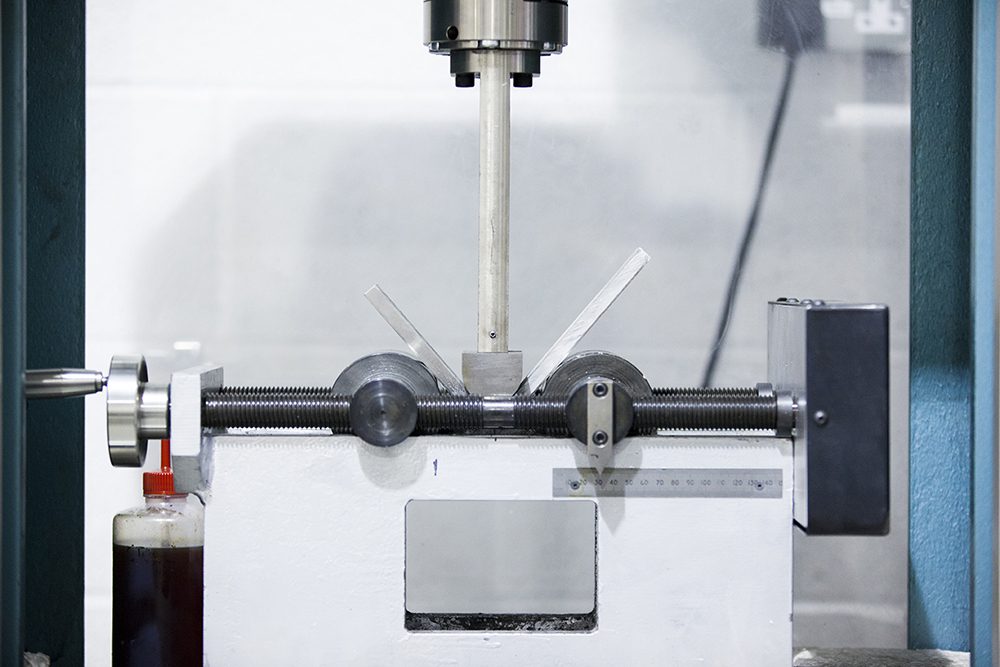

Destructive Weld Testing evaluates joint strength and integrity by applying stress to the weld until failure.

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Metallography at BES Group

Explore all sub-services- Comprehensive Metallography services for in-depth metal analysis

- Combine Metallography with mechanical testing for a complete analysis

- Key benefits of Metallography

Unlock the secrets of metal structures with expert Metallography

Metallography is an essential tool for understanding the internal structures of metals and alloys, providing vital information for material characterisation, quality control, research, and troubleshooting across industries like manufacturing, engineering, and materials science.

Our service starts with preparing metal samples for microscopic examination. This process involves cutting, mounting, grinding, polishing, and etching the specimens to reveal their internal structures for analysis.

Once the samples are prepared, we perform a range of investigative tests for a thorough analysis:

- Microstructure evaluation, phase distribution, and defect assessments

- Inclusion content, grain size determinations

- Graphite type, size, distributions in cast irons

- Macro and Micro Examinations for the determination of heat treatment condition, case depth, and material cleanliness

- Decarburisation tests

- Ferrite counts, volume fraction, determinations by image analysis

- Corrosion Testing

- Failure Investigations, SEM/EDX Analysis, and Fracture Analysis

All your metals testing needs, under one roof.

Sending samples to multiple labs can be frustrating, costly, and may lead to inconsistent results. At our laboratory, we offer a complete range of destructive testing services, all in one place.

Our in-house team prepares your samples and conducts a thorough analysis, including tensile, impact, hardness testing, and more, all in our UKAS-accredited lab. This streamlined process ensures consistent and reliable results without the hassle of using multiple labs.

We aim to complete all tests within a 3-day turnaround, including:

- Sample preparation and machining

- Tensile, Impact, and Hardness testing

- Chemical Analysis

- Metallurgical Examinations

- Corrosion Analysis

Optional services include Salt Spray Testing, Weld Assessments, and Coating Finish Testing. We’re here to simplify your testing needs, providing a comprehensive service from start to finish.

In-Depth Material Analysis

Metallography provides a detailed examination of a material’s microstructure, allowing for a better understanding of its composition, grain size, and phase transformations, which are critical for predicting performance.

Improved Quality Control

By identifying defects, inclusions, and other irregularities, metallography ensures the material meets the required standards for strength, durability, and corrosion resistance, enhancing the quality of your products.

Enhanced Durability and Reliability

Through microstructure evaluations and failure investigations, metallography enables better material selection, increasing the longevity and performance of metals in harsh environments.

-

Comprehensive Metallography services for in-depth metal analysis

Unlock the secrets of metal structures with expert Metallography

Metallography is an essential tool for understanding the internal structures of metals and alloys, providing vital information for material characterisation, quality control, research, and troubleshooting across industries like manufacturing, engineering, and materials science.

Our service starts with preparing metal samples for microscopic examination. This process involves cutting, mounting, grinding, polishing, and etching the specimens to reveal their internal structures for analysis.

Once the samples are prepared, we perform a range of investigative tests for a thorough analysis:

- Microstructure evaluation, phase distribution, and defect assessments

- Inclusion content, grain size determinations

- Graphite type, size, distributions in cast irons

- Macro and Micro Examinations for the determination of heat treatment condition, case depth, and material cleanliness

- Decarburisation tests

- Ferrite counts, volume fraction, determinations by image analysis

- Corrosion Testing

- Failure Investigations, SEM/EDX Analysis, and Fracture Analysis

-

Combine Metallography with mechanical testing for a complete analysis

All your metals testing needs, under one roof.

Sending samples to multiple labs can be frustrating, costly, and may lead to inconsistent results. At our laboratory, we offer a complete range of destructive testing services, all in one place.

Our in-house team prepares your samples and conducts a thorough analysis, including tensile, impact, hardness testing, and more, all in our UKAS-accredited lab. This streamlined process ensures consistent and reliable results without the hassle of using multiple labs.

We aim to complete all tests within a 3-day turnaround, including:

- Sample preparation and machining

- Tensile, Impact, and Hardness testing

- Chemical Analysis

- Metallurgical Examinations

- Corrosion Analysis

Optional services include Salt Spray Testing, Weld Assessments, and Coating Finish Testing. We’re here to simplify your testing needs, providing a comprehensive service from start to finish.

-

Key benefits of Metallography

In-Depth Material Analysis

Metallography provides a detailed examination of a material’s microstructure, allowing for a better understanding of its composition, grain size, and phase transformations, which are critical for predicting performance.

Improved Quality Control

By identifying defects, inclusions, and other irregularities, metallography ensures the material meets the required standards for strength, durability, and corrosion resistance, enhancing the quality of your products.

Enhanced Durability and Reliability

Through microstructure evaluations and failure investigations, metallography enables better material selection, increasing the longevity and performance of metals in harsh environments.

Frequently asked questions

What industries benefit from Metallography Testing?

Metallography is essential in industries like manufacturing, engineering, aerospace, automotive, and materials science. It helps ensure the durability, strength, and reliability of materials used in critical applications such as machinery, infrastructure, and components.

What types of defects can Metallography detect?

Metallography can identify a wide range of defects such as cracks, voids, inclusions, porosity, and other irregularities in the microstructure. These insights are crucial for assessing material integrity and preventing failures in products and components.

Can Metallography be used to assess heat treatment processes?

Yes, Metallography is particularly useful in evaluating the effectiveness of heat treatments like annealing, quenching, and tempering. It helps analyse changes in grain size, phase distribution, and other microstructural features that influence material properties.

How long does Metallography Testing take?

The duration of Metallography Testing depends on the complexity of the sample and the tests required. Typically, we aim to complete the process within a few days, but the timeline may vary based on the specifics of the project.

Is Metallography Testing suitable for all types of metals?

Yes, Metallography is applicable to a wide variety of metals and alloys, including ferrous and non-ferrous materials, castings, forgings, and welded components. It provides valuable insights into the properties and performance of almost any material.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team