Asset Reliability

Condition Monitoring Solutions

We provide industry leading Condition Monitoring services to help you find asset problems before they cause critical issues – whether that’s unscheduled downtime or complete asset failure.

Explore our Condition Monitoring Solutions

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with...

Our Condition Monitoring Solutions

Condition Monitoring is a predictive maintenance approach that involves identifying underlying problems. Our specialist engineers collect and analyse data from the asset, including temperature, vibration, and oil condition to identify any irregularities. If an anomaly is detected within the data, it could indicate repair or replacement is needed.

Oil Analysis

Oil Analysis focuses on oil machinery, asset health and monitoring lubricating oils.

Ultrasonic Condition Monitoring

Ultrasonic Condition Monitoring identifies ultrasonic frequencies that could indicate mechanical faults.

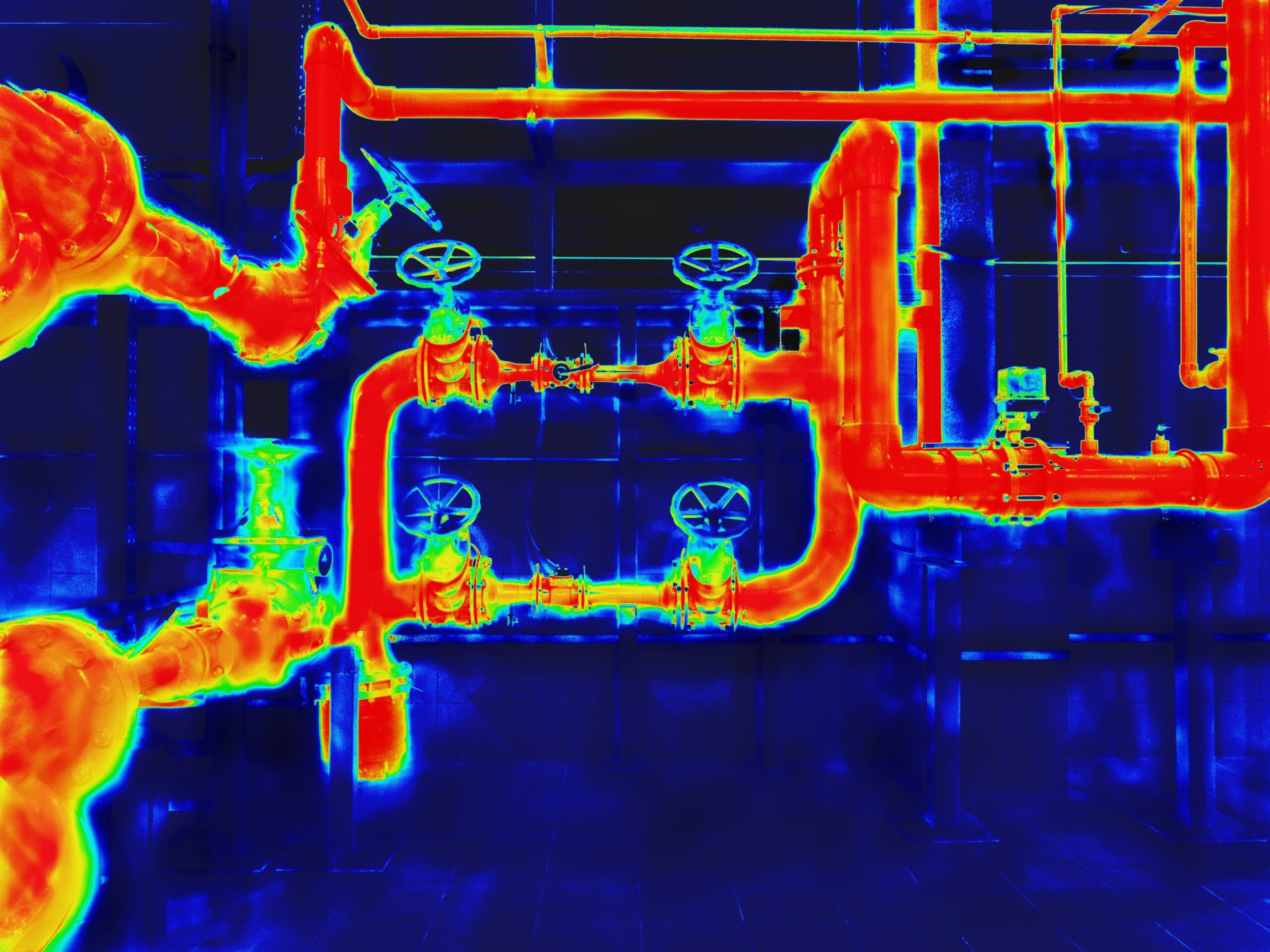

Thermographic Surveys

Thermographic Surveys use thermal imaging technology to identify potential heat problems within your assets.

Video Deflection and ODS

Video Deflection and ODS captures issues within your equipment, such as structural defects.

Vibration Analysis

Vibration Analysis reviews excessive vibrations, unusual noises, and other signs of damage.

Motor and Current Analysis

Motor and Current Analysis uses currents from an electric motor to help you detect asset issues early.

Let's talk about Condition Monitoring Solutions

Send us an enquiry

Not seeing what you expected?

Try using our search

Explore what our clients say

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Power and Utilities

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Rail

Explore sector

Retail

Explore sector

Renewables

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Condition Monitoring at BES Group

Explore all sub-services- What can Condition Monitoring be applied to?

- How can Condition Monitoring maintain your assets?

- Key benefits of Condition Monitoring

Asset Condition Monitoring can be used to monitor a wide range of equipment, including rotating machinery, static machinery, and process assets.

At BES Group, our engineers are here to find the right service for your assets and the unique requirements of your industry. Our Condition Monitoring services rely heavily on data. This allows us to predict problems early, ensuring you have a clearer picture of when assets might fail – even before they do. A fully comprehensive Condition Monitoring report is provided with each service.

Condition Monitoring is relevant across various industries such as:

- Manufacturing

- Hospitality

- Agriculture

- Pharmaceutical

- Marine and Offshore

- Oil and Gas

- Aerospace

Equipment can fail for many reasons, one of the most common issues is general wear and tear over time.

If your assets are demonstrating unusual vibrations and noises, unexplained high temperatures, or inefficiencies with production and quality, this indicates that your assets need to be examined.

Condition Monitoring can detect and diagnose problems before they cause issues for your business. It could be a singular part of a machine close to failure, but this can have a drastic effect on your overall operations. One part could lead to the entire machine shutting down, creating unplanned downtime and disrupted operations. Condition Monitoring involves proactive maintenance, so you can correct these issues early and prevent unnecessary losses.

Reduce cost

Identify problems early so you can schedule cost-effective repairs, rather than full asset replacement when it fails.

Minimise downtime

Diagnose problems before they turn into critical issues like equipment failure, so you can keep operations running seamlessly.

Improve efficiency

Detect issues that could affect the efficiency of your assets and avoid operational issues affecting business productivity or output.

-

What can Condition Monitoring be applied to?

Asset Condition Monitoring can be used to monitor a wide range of equipment, including rotating machinery, static machinery, and process assets.

At BES Group, our engineers are here to find the right service for your assets and the unique requirements of your industry. Our Condition Monitoring services rely heavily on data. This allows us to predict problems early, ensuring you have a clearer picture of when assets might fail – even before they do. A fully comprehensive Condition Monitoring report is provided with each service.

Condition Monitoring is relevant across various industries such as:

- Manufacturing

- Hospitality

- Agriculture

- Pharmaceutical

- Marine and Offshore

- Oil and Gas

- Aerospace

-

How can Condition Monitoring maintain your assets?

Equipment can fail for many reasons, one of the most common issues is general wear and tear over time.

If your assets are demonstrating unusual vibrations and noises, unexplained high temperatures, or inefficiencies with production and quality, this indicates that your assets need to be examined.

Condition Monitoring can detect and diagnose problems before they cause issues for your business. It could be a singular part of a machine close to failure, but this can have a drastic effect on your overall operations. One part could lead to the entire machine shutting down, creating unplanned downtime and disrupted operations. Condition Monitoring involves proactive maintenance, so you can correct these issues early and prevent unnecessary losses.

-

Key benefits of Condition Monitoring

Reduce cost

Identify problems early so you can schedule cost-effective repairs, rather than full asset replacement when it fails.

Minimise downtime

Diagnose problems before they turn into critical issues like equipment failure, so you can keep operations running seamlessly.

Improve efficiency

Detect issues that could affect the efficiency of your assets and avoid operational issues affecting business productivity or output.

Frequently asked questions

How often should you carry out Condition Monitoring?

The frequency of Condition Monitoring depends on several factors, including the type of asset, operating environment, and level of risk tolerance.

Generally, important assets need monitoring weekly or monthly. Critical assets for safety, production, or in harsh conditions should undergo Condition Monitoring more frequently, potentially hourly or daily.

They can be monitored continuously through a permanently installed wireless or online vibration sensor to ensure a reduction in potential financial losses. All other assets can be assessed quarterly or annually.

What are the different types of Condition Monitoring?

BES Group offers many types of Condition Monitoring, including:

- Vibration Analysis

- Oil Analysis

- Thermography

- Ultrasonic Condition Monitoring

- Video Deflection

- ODS Motor and Current Analysis

What can affect the accuracy of Condition Monitoring?

The most important feature for accuracy is the condition of the asset. Assets in good condition are easier to monitor than those in poor condition, so it’s advisable to set up monitoring at the beginning of an asset’s lifespan.

The type of Condition Monitoring you choose is also important, as these services are specialised to your industry and equipment. You need an expert to conduct Condition Monitoring too. The engineer must be suitably qualified to perform tests, so they know exactly what they’re looking for.

Which industries can Condition Monitoring be used for?

Condition Monitoring is used across many industries, including:

- Food and Beverage

- Marine and Offshore

- Manufacturing

- Oil and Gas

- Power and Utilities

- Rail

- Renewables

- Retail

- Aerospace and Defence

- Agriculture

- Automotive

- Healthcare

- Hospitality and Leisure

- Insurance

At BES Group, we’ll work with you to create a bespoke condition monitoring plan that aligns with your industry and asset needs. That way, we ensure you receive the most accurate insights into your equipment’s health.

Read our UK ferry operator case study and testing subsea airbags case study to learn more about our applications in various industries.

What are the advantages of Condition Monitoring?

The biggest benefit of Condition Monitoring is that it allows for proactive and predictive maintenance. Using trackable data from Condition Monitoring reports, it gives you insights into which assets aren’t performing optimally and where issues may arise.

This allows you to schedule maintenance early. In doing so, it helps prevent unscheduled downtime, equipment failure, expensive repair works and reduce energy inefficiency.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team