Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

Sector

Manufacturing

Location

Port Talbot, Wales

Services

Condition Monitoring

Lubrication Services

Our partnership with Tata Steel Ltd.

Overview

TATA Steel UK is one of Europe’s leading strip steel manufacturers with steelmaking facilities located at Port Talbot, Wales, which can produce nearly 5 million tonnes of steel slab per annum. We provided an asset management programme to reduce overall maintenance costs.

We currently provide TATA Steel UK with a condition monitoring service to monitor, analyse and report on the condition of all rotational equipment at TATA Steel, Port Talbot, Morfa Coke Ovens (MCO).

The challenge

The solution

The result

During the contract period, the following results were achieved:

- Condition Monitoring (CM) routes increased from 100 to 400 assets by utilising the same labour

- Alignments carried out when new assets are fitted

- Identified and addressed oil blending issues across site

- Equipment downtime decreased

- Routine lubrication of all motor bearings

- Lubrication survey carried out on all conveyor drum cooper bearings

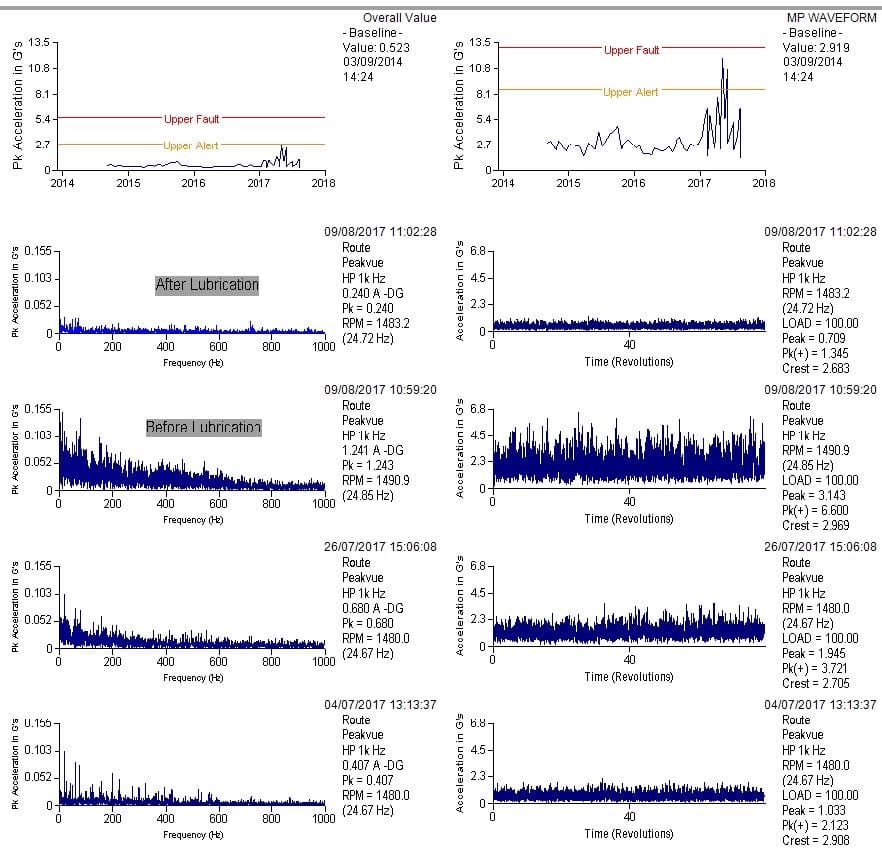

- Manual lubrication of rotating components vibration data shows excessive levels due to insufficient grease (see figure 1)

- MCO planning improved due to accurate our weekly reporting

- Safety critical failures prevented due to routine condition monitoring, accurate trending and asset knowledge

- Asset installation testing – reduction in start-up failures/damage

- Entry of SAP maintenance requests when oil changes required as dictated by oil analysis results

- IMAD proposal for ‘Critical’ Turbine and Booster online monitoring tendered

- IMAD proposal for fixed/wireless sensors for assets

- Production of KPI figures to track the number of healthy/critical assets

Figure 1: Excessive vibration levels caused by insufficient grease.

Key outcomes

Condition monitoring routes increased from 100 to 400 assets.

Equipment downtime decreased.

MCO planning improved due to accurate weekly reporting.

Safety critical failures prevented.

Asset installation testing reduced start-up failures/damage.

Contact us to find out more about our Condition Monitoring and Lubrication Services

Related Case Studies

View All Case Studies

Preserving History and Ensuring Safety with Structural Monitoring During The Jenners Building Re-development

Read more.

Vessel Downtime Avoided for UK Ferries Operator

Read more.