Hardness Testing

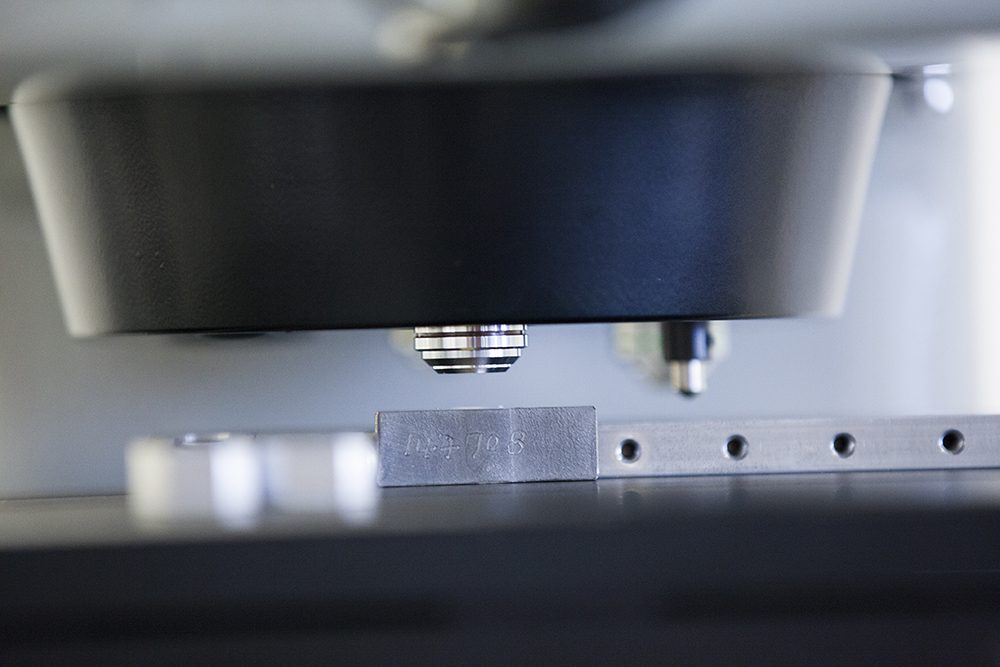

Rockwell Hardness Testing

Rockwell Hardness Testing is a simple and effective way to measure the strength and durability of your samples.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Rockwell Hardness Testing?

The Rockwell Hardness Test is a popular and easy way to measure the hardness of metals. The test measures how resistant a material is to mechanical forces such as scratching, cutting, or compressing.

The Rockwell Hardness Test is ideal for determining the hardness of bulk metals because it uses heavy loads and is cost-effective. It is known for its speed, simplicity and non-destructive nature, as it only leaves a small indentation on the material.

With the Rockwell Hardness scale, you can directly read the hardness level without the need for extra measurements or calculations required by other hardness tests.

Who we've partnered with...

Key benefits

Speed and Efficiency

Rockwell testing provides rapid results, making it ideal for high-throughput environments.

Versatility

Applicable to a wide range of materials, including metals, polymers, and composites.

Non-Destructive

The test does not significantly alter the material, allowing for continued use of the sample.

Cost-Effective

Generally less expensive to perform compared to other hardness tests like Brinell or Vickers.

Let's talk about Rockwell Hardness Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we’ll work with you

We focus on providing personalised and reliable Rockwell Hardness Testing services to meet your specific needs. We begin by discussing your material testing requirements, understanding your goals, and identifying any industry standards that may apply.

Combine Rockwell Hardness Testing with our range of Destructive Tests.

We can perform Rockwell Hardness Testing alongside other Mechanical Tests, such as Tensile Testing or Impact Testing, to give you a complete mechanical overview of your material’s performance. This comprehensive approach ensures a thorough evaluation of your metal’s strength, toughness, and overall durability.

Our process

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What Rockwell Hardness scales do you work to?

There are multiple versions of Rockwell Hardness Scales available, which vary depending on the material being tested. Each scale utilizes different loads or indenters, enabling us to test materials of varying hardness:

- HRB scale is specifically designed for testing aluminium, brass, and soft steels, with minor loads of 10kgf and major loads of 100kgf applied.

- HRC is used for hard steels, hard cast irons, and deep case hardened steel, with minor loads of 10kgf and major loads of 150kgf applied.

What materials can be tested using the Rockwell method?

The Rockwell Hardness Test is suitable for a wide range of metals, such as aluminium, copper alloys, brass, soft steels, and hard carbon steels.

How does the Rockwell Test compare to other Hardness Tests?

The Rockwell Test is generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the test, reducing wastage during the testing process.

Let's talk about Rockwell Hardness Testing

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team