Hardness Testing

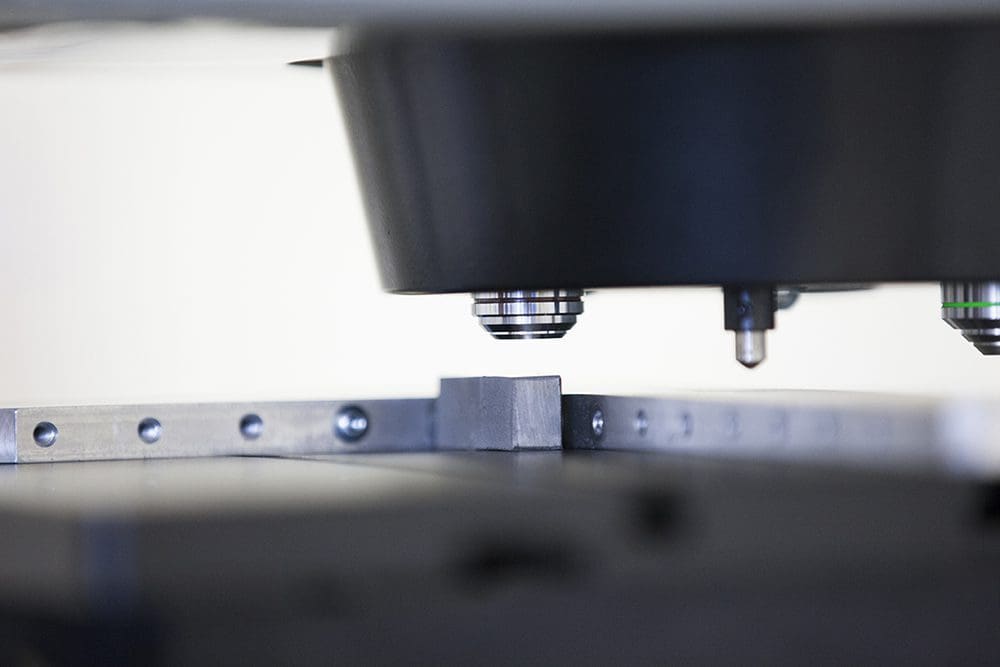

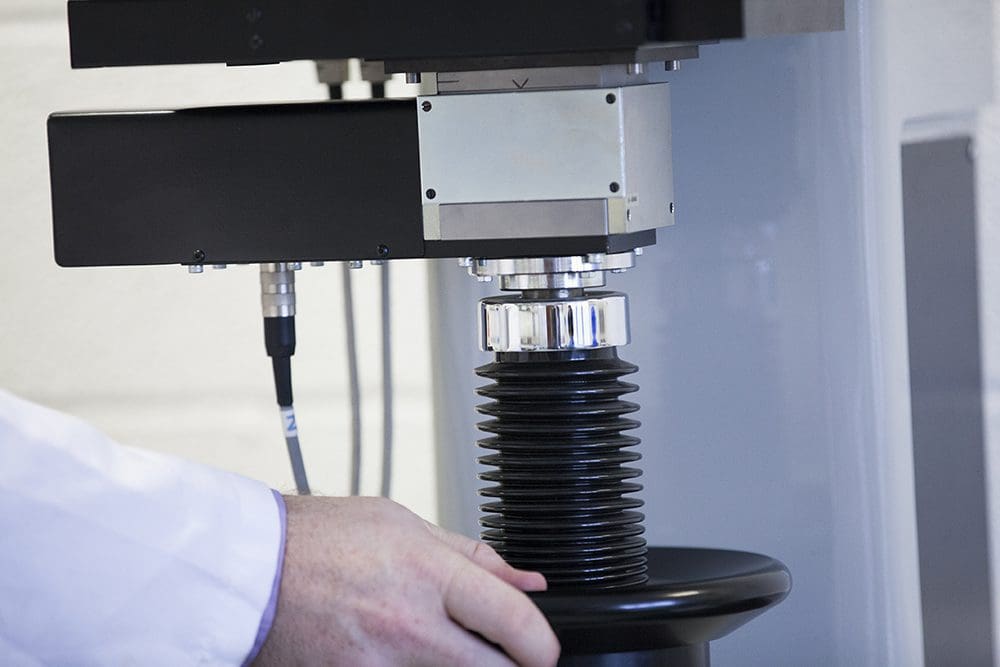

Microhardness Testing

Microhardness tests offer precise and accurate insights into materials characterised by fine microstructures, typically for thin metals using extremely light loads.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Microhardness Testing?

Microhardness Testing is a specialised technique used to determine the hardness of small-scale specimens or thin sections with exceptional precision.

This allows for a more detailed and localised analysis compared to standard hardness tests, leading to a deeper understanding of how materials behave under different conditions and environments.

The meticulous nature of Microhardness Testing enables practitioners to identify subtle differences in hardness distribution, helping to pinpoint potential weak points, defects, or variations within the material’s structure.

As a result, this level of detail enhances the precision of material characterisation and enables more informed decision-making in areas such as material selection, process optimisation, and quality control.

Who we've partnered with...

Key benefits

Precision

Microhardness testing enables accurate measurement in small or delicate samples.

Versatility

Suitable for thin coatings, small samples, and in-depth microstructural analysis.

Non-Destructive

Testing does not damage the sample, ensuring that it can still be used after testing.

Comprehensive Analysis

Microstructural examinations means that you can gain detailed insights into your metal's properties.

Let's talk about Microhardness Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

We work closely with you to understand your specific testing needs, create a customized testing plan, prepare your samples, perform precise microhardness tests, and deliver detailed reports with actionable insights.

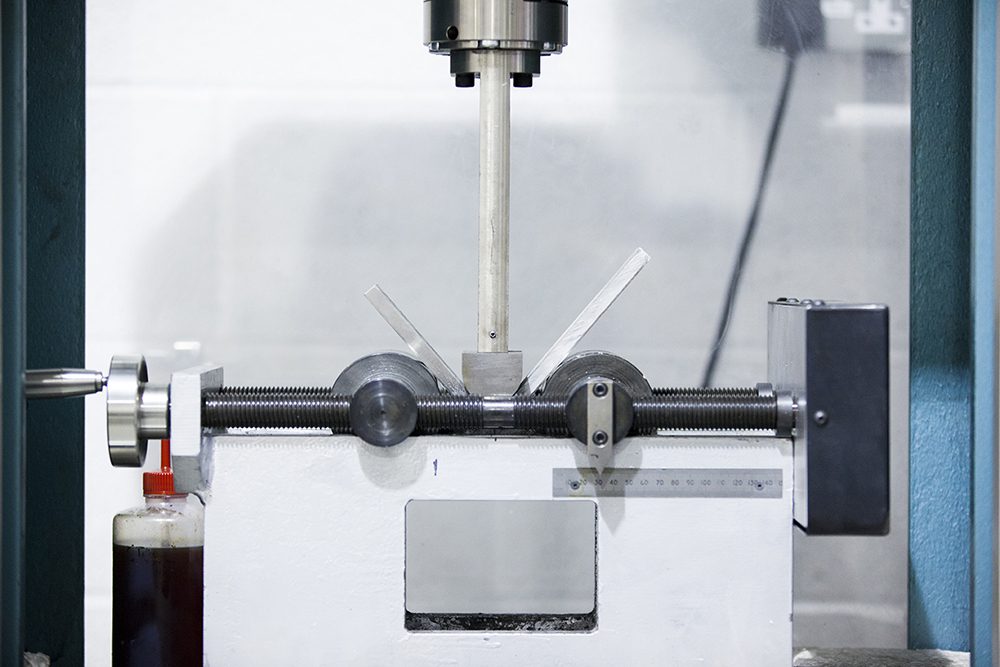

Combine Microhardness Testing with our range of Destructive Tests.

Microhardness Testing can also be combined with other tests, such as Tensile and Impact Testing, to give you a complete understanding of your material’s mechanical properties.

For a thorough, comprehensive analysis, we can integrate Microhardness Testing with our Metallurgical Tests and microscopic examinations, providing you with peace of mind regarding the performance and durability of your metals.

Knoop & Vickers Microhardness Tests

We offer both Knoop and Vickers Microhardness Testing methods.

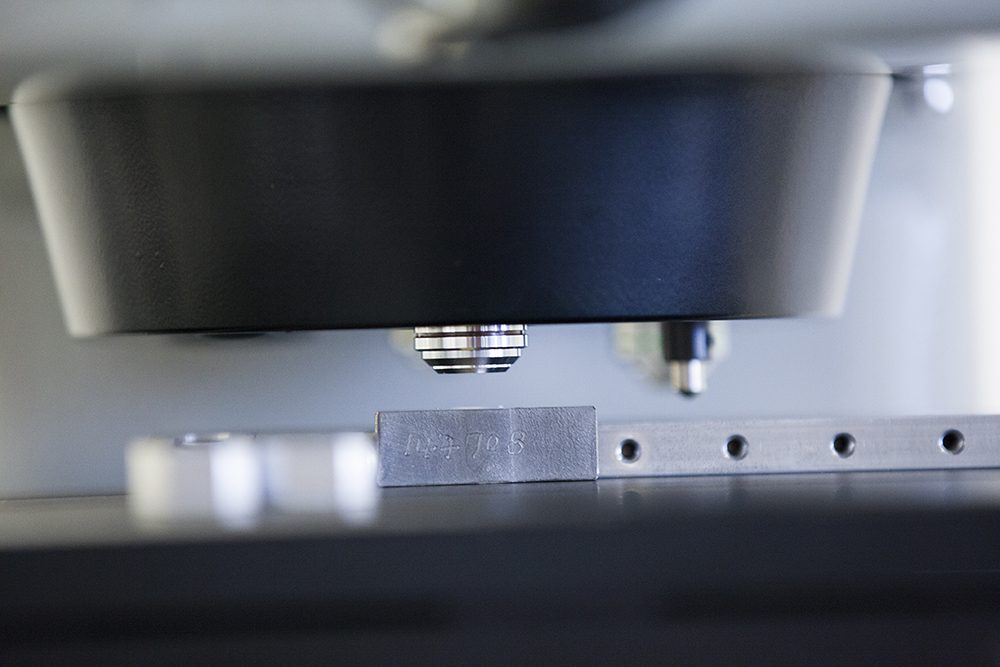

Knoop Microhardness Testing

Knoop Hardness Testing uses an elongated pyramid-shaped diamond to press into the material’s surface, creating a measurable impression that yields a specific hardness result.

It is ideal for examining various phases within a material, including Austenite/Ferrite phases in duplex materials or assessing hardness differences within banded microstructures.

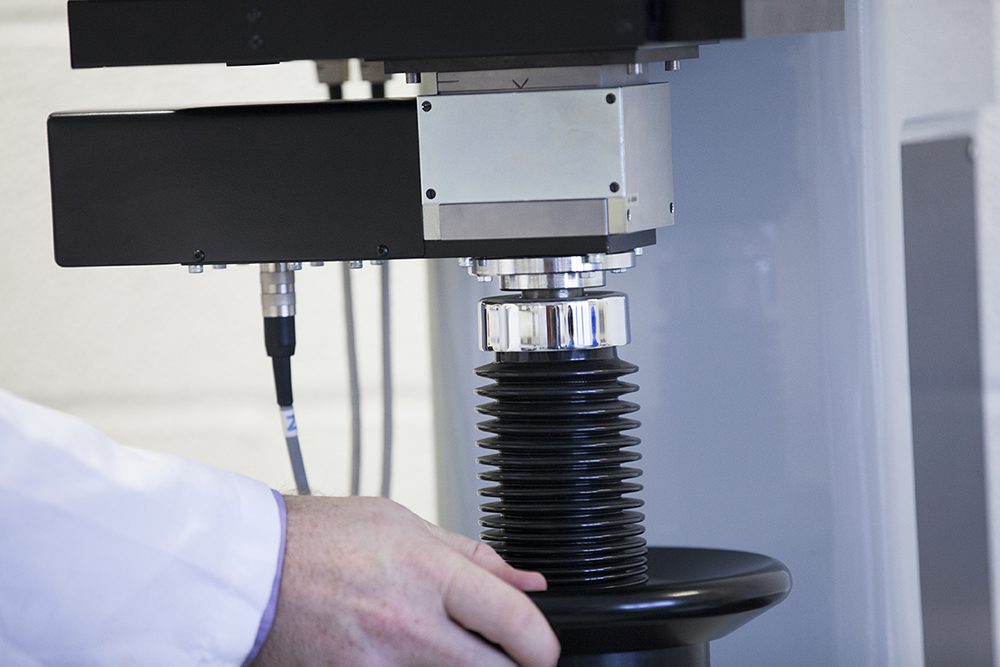

Vickers Microhardness Testing

The Vickers Microhardness Test uses a pyramid-shaped indenter applying a constant load, specifically on delicate samples.

Vickers Microhardness Testing is particularly well-suited for fragile samples that demand very low loads. It is suitable for a wide range of materials, providing reliable hardness measurements.

Our process

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What Knoop Hardness Testing standards do you work to?

We offer Knoop Hardness Testing to ISO 4545-1:2018

What Vickers Microhardness Testing standards do you work to?

We carry out Vickers Microhardness Testing to the following standards:

- BS EN ISO 6507-1:2018

- ASTM E384 Micro indentations

- Microhardness Vickers tests (HV0.1)

How does Microhardness Testing differ to hardness testing?

Unlike traditional hardness testing methods like Rockwell or Brinell, which are mainly performed on larger samples, Microhardness Testing focuses on examining tiny and specific areas of a material.

This approach is particularly beneficial when dealing with small or delicate samples, as well as when evaluating variations in hardness within a material’s different phases or structures.

What applications is Microhardness Testing ideal for?

Microhardness Testing is ideal for a variety of applications, including:

- Coating hardness

- Surface hardness

- Case depth measurement

- Hardness testing of fragile or brittle metals

- Identifying microstructural hardness variations

What is Microhardness Testing used for?

Microhardness Testing is ideal for assessing smaller or fragile materials and is commonly used for:

- Thin Film Evaluation: Measuring hardness of thin coatings.

- Phase Identification: Identifying hardness variations in different material phases.

- Heat Treatment Assessment: Evaluating heat treatment effects on localized areas.

- Microstructure Analysis: Studying specific microstructural features in metals.

- Small-Scale Sample Testing: Testing small or delicate samples where traditional methods may not work.

It provides detailed insights into the mechanical properties of materials.

Let's talk about Microhardness Testing

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team