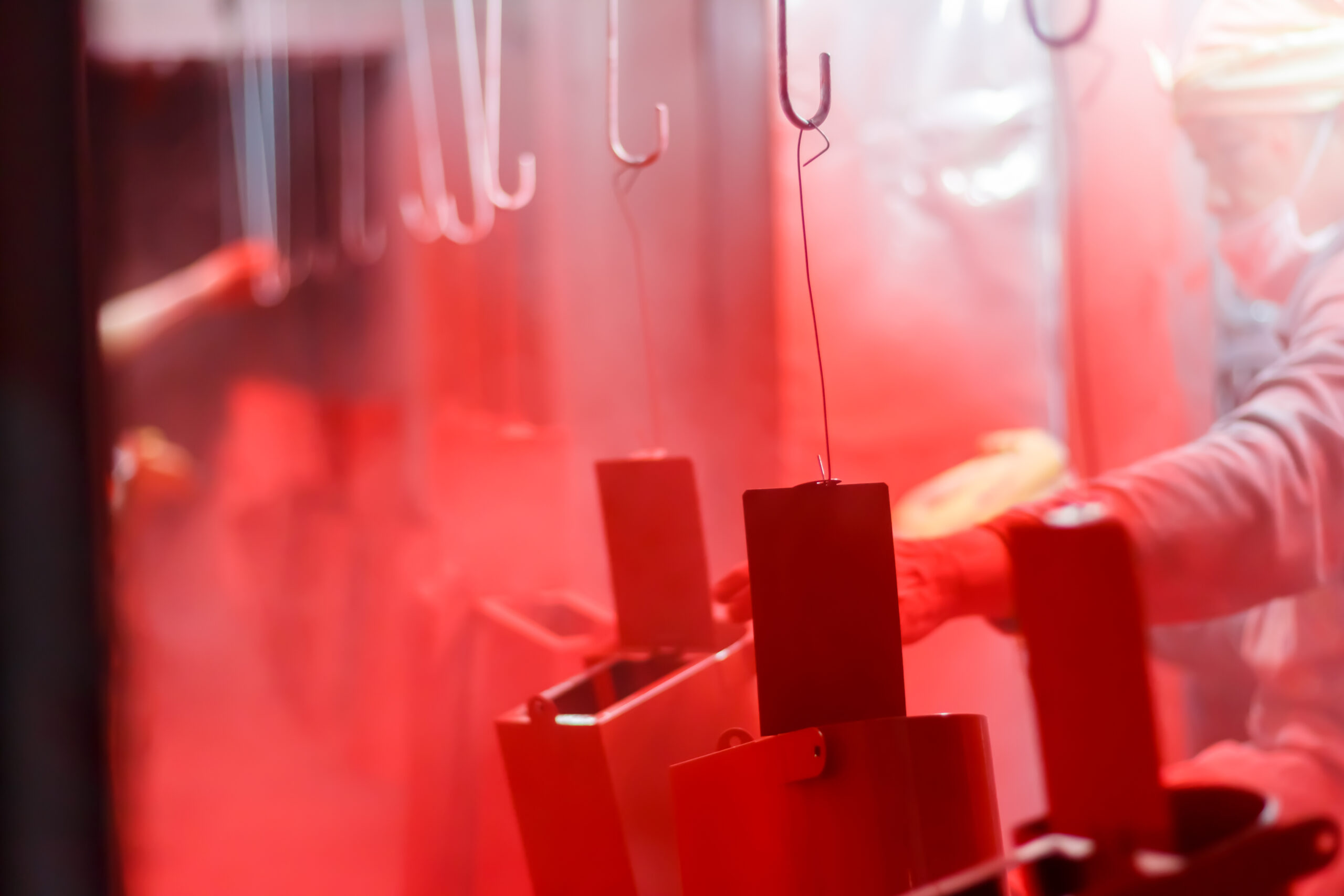

Finish Testing

Salt Spray Testing

Salt Spray Testing, also known as Salt Fog Testing or Salt Corrosion Testing, is a method to assess how well coatings and surface treatments can withstand corrosion.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Salt Spray Testing?

Coatings and finishes serve as a shield to protect materials, and the salt spray test helps determine the effectiveness of these protective layers. It also provides insights into the product’s resistance or susceptibility to corrosion in real-world conditions.

This involves exposing samples to a controlled saline (saltwater) environment to simulate the corrosive conditions that materials may face in real-world settings, such as coastal or marine environments.

Various international standards provide guidelines for conducting salt spray testing. We work to the following Salt Spray Testing standards:

- ASTM B117 – Standard practice for operating salt spray (fog) apparatus.

- BS EN ISO 9227 – Method for salt spray corrosion tests in artificial atmospheres.

Who we've partnered with...

Key benefits

Expert Corrosion Assessment

By exposing samples to a controlled saline environment, Salt Spray Testing simulates corrosive conditions, providing rapid insights into how materials will perform over time.

Quality Assurance

Salt Spray Testing helps verify the effectiveness of protective coatings, ensuring they meet industry standards and perform as intended in real-world environments.

Comparative Analysis

Salt Spray Testing allows for the comparison of different coatings and materials, aiding in the selection of the most suitable protective finish for specific applications.

Cost-Effective Evaluation

As an inexpensive, standardised method, Salt Spray Testing provides valuable data on corrosion resistance without prolonged field exposure, saving time and resources.

Let's talk about Salt Spray Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

At BES Group, we pride ourselves on delivering a collaborative and transparent testing experience that ensures the highest standards and the most relevant results for your project.

Assessing accelerated corrosion in a controlled environment.

Salt Spray Testing is conducted under controlled conditions, ensuring consistency and reliability. You can expect a clear understanding of how your product will hold up to corrosive environments based on established standards such as ASTM B117 or ISO 9227.

We’re your trusted advisor for Salt Spray Testing.

By partnering with BES Group, you can count on a thorough, precise, and customised approach to salt spray testing that delivers the information you need to make critical decisions about your materials and coatings.

Our process

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

Why should I choose Salt Spray Testing for my product?

Salt Spray Testing helps determine how well your products or materials will withstand corrosion over time.

It’s particularly useful for industries like automotive, aerospace, marine, and manufacturing, where long-term durability in harsh environments is essential.

What standards are used in Salt Spray Testing?

We follow recognised industry standards for Salt Spray Testing, including ASTM B117 and ISO 9227.

These standards ensure consistent, reliable results that can be used for quality control, regulatory compliance, or material selection.

How long does Salt Spray Testing take?

The duration of Salt Spray Testing can vary depending on the material and the severity of testing conditions.

Typically, tests range from 24 hours to several weeks. We’ll work with you to determine the appropriate test duration based on your needs.

What types of materials can be tested?

Salt Spray Testing is suitable for a wide range of materials, including metals (e.g., steel, aluminium, brass), coatings, paints, and finishes. If you’re unsure whether your material is suitable for testing, feel free to reach out to our team, and we’ll guide you.

Let's talk about Salt Spray Testing

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team