Destructive Testing

Finish Testing

BES Group is a UKAS accredited metallurgical testing laboratory to ISO/IEC 17025 and is fully equipped to meet your specific needs and requirements for finish testing.

Explore our process

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with

What is Finish Testing?

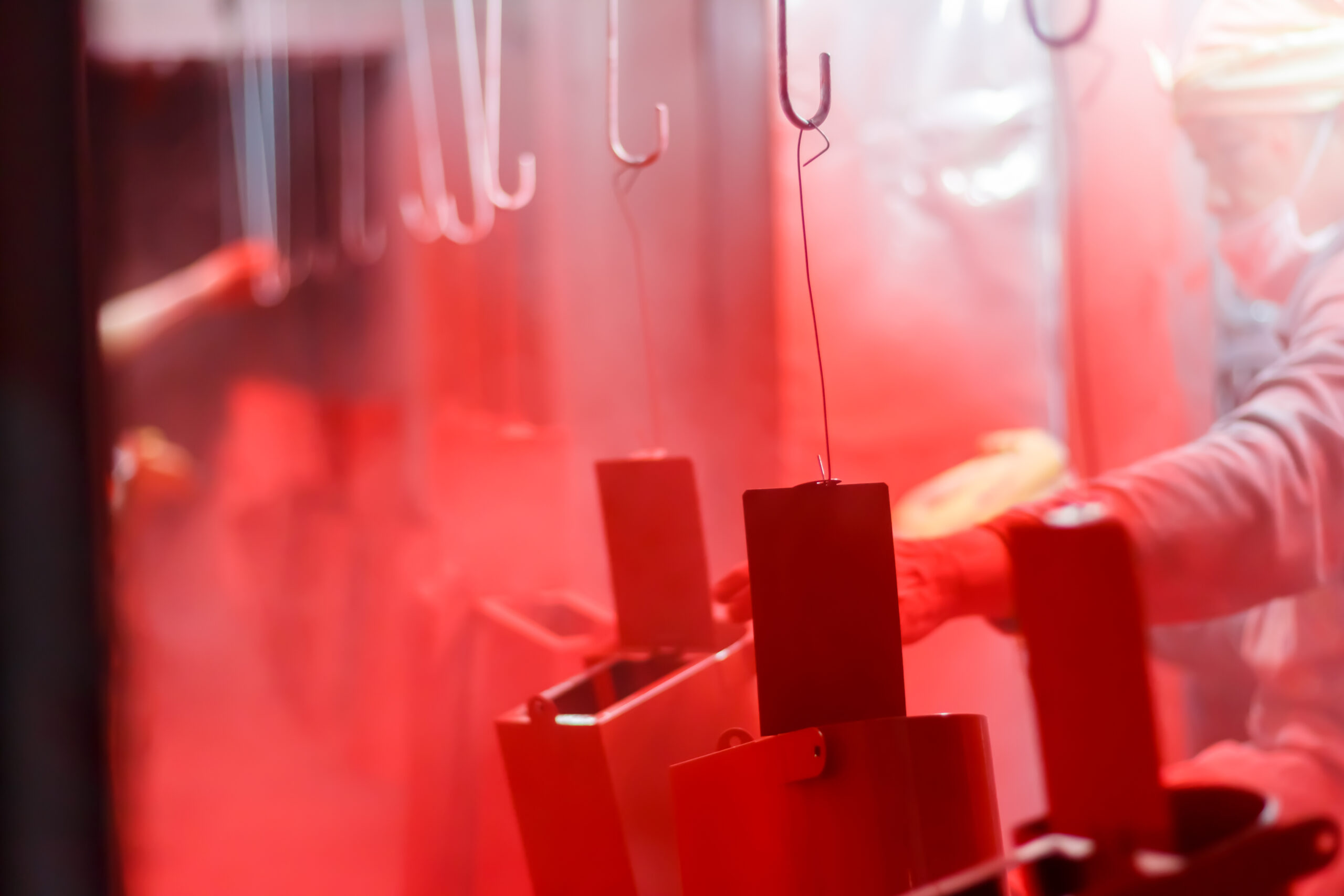

Finish testing refers to a number of testing procedures that are used to assess the final appearance, surface quality or overall finish of a product or material. These type of tests aim to analyse the coatings, platings or paints that have been applied to a sample, so we can evaluate their corrosion resistance and ability to act as a protective barrier to the material when used in real-life conditions. Our laboratory provides an extensive range of disciplines for testing which can help deliver the guidance and assurance needed to validate and develop your products with confidence.

Humidity Testing

Assess how your materials or products respond to elevated humidity levels.

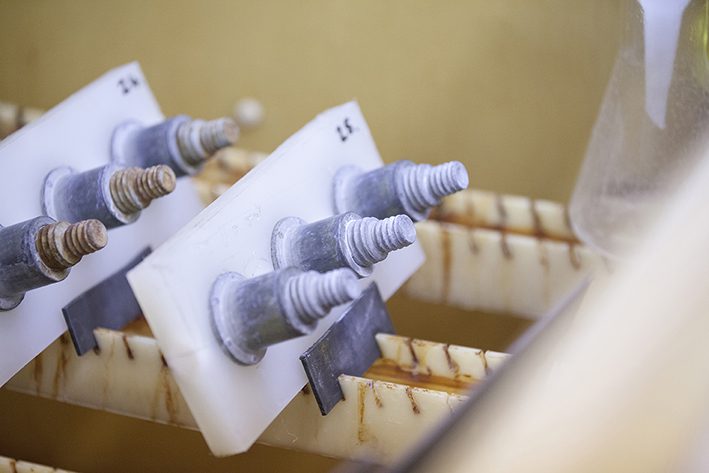

Salt Spray Testing

Understand how well coatings and surface treatments can withstand corrosion.

Coating Finish Testing

Evaluate the quality, performance and characteristics of applied coatings on fastener or metal products.

Let's talk about Finish Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Finish Testing Services from BES Group

Explore all sub-services- Why choose Finish Testing?

- Types of Finish Testing Services Offered

Gain accurate, comparative insights

Finish testing aims to provide clients with accurate comparative data to show the capability of different products and to demonstrate which of those products gives the best performance.

We also offer accelerated corrosion tests to analyse the performance of materials when subjected to harsh environmental conditions, such as saltwater, marine or corrosive atmospheres.

The combination of both salt spray testing and finish testing can be beneficial in assessing the corrosion resistance of a finished product, and is especially crucial for automotive, aerospace or marine industries. Finish testing ensures that not only the surface appearance but also the protective coatings or finish meet quality standards when exposed to harsh environments.

Comprehensive Finish Testing Services

- Fully equipped Coating Testing Laboratory

- Paint, phosphate, electroplate and plastic coating testing and assessments

- Neutral salt spray tests to ASTM B117 and BS EN ISO 9227

- Humidity resistance tests*

- Coating thickness, adhesion, coating weight and hardness testing

- Resistance to petrol, solvents, hot oil, antifreeze, heat

- Cross Cut Adhesion to BS EN ISO 2409

- Dry Heat

- Pencil Hardness

- Immersion Testing

- Freeze Testing*

- Coating mass & Coating Thickness

- Hexavalent Chromium (Cr6) Testing

The activities identified with * are not UKAS accredited

-

Why choose Finish Testing?

Gain accurate, comparative insights

Finish testing aims to provide clients with accurate comparative data to show the capability of different products and to demonstrate which of those products gives the best performance.

We also offer accelerated corrosion tests to analyse the performance of materials when subjected to harsh environmental conditions, such as saltwater, marine or corrosive atmospheres.

The combination of both salt spray testing and finish testing can be beneficial in assessing the corrosion resistance of a finished product, and is especially crucial for automotive, aerospace or marine industries. Finish testing ensures that not only the surface appearance but also the protective coatings or finish meet quality standards when exposed to harsh environments.

-

Types of Finish Testing Services Offered

Comprehensive Finish Testing Services

- Fully equipped Coating Testing Laboratory

- Paint, phosphate, electroplate and plastic coating testing and assessments

- Neutral salt spray tests to ASTM B117 and BS EN ISO 9227

- Humidity resistance tests*

- Coating thickness, adhesion, coating weight and hardness testing

- Resistance to petrol, solvents, hot oil, antifreeze, heat

- Cross Cut Adhesion to BS EN ISO 2409

- Dry Heat

- Pencil Hardness

- Immersion Testing

- Freeze Testing*

- Coating mass & Coating Thickness

- Hexavalent Chromium (Cr6) Testing

The activities identified with * are not UKAS accredited

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team