Finish Testing

Coating Finish Testing

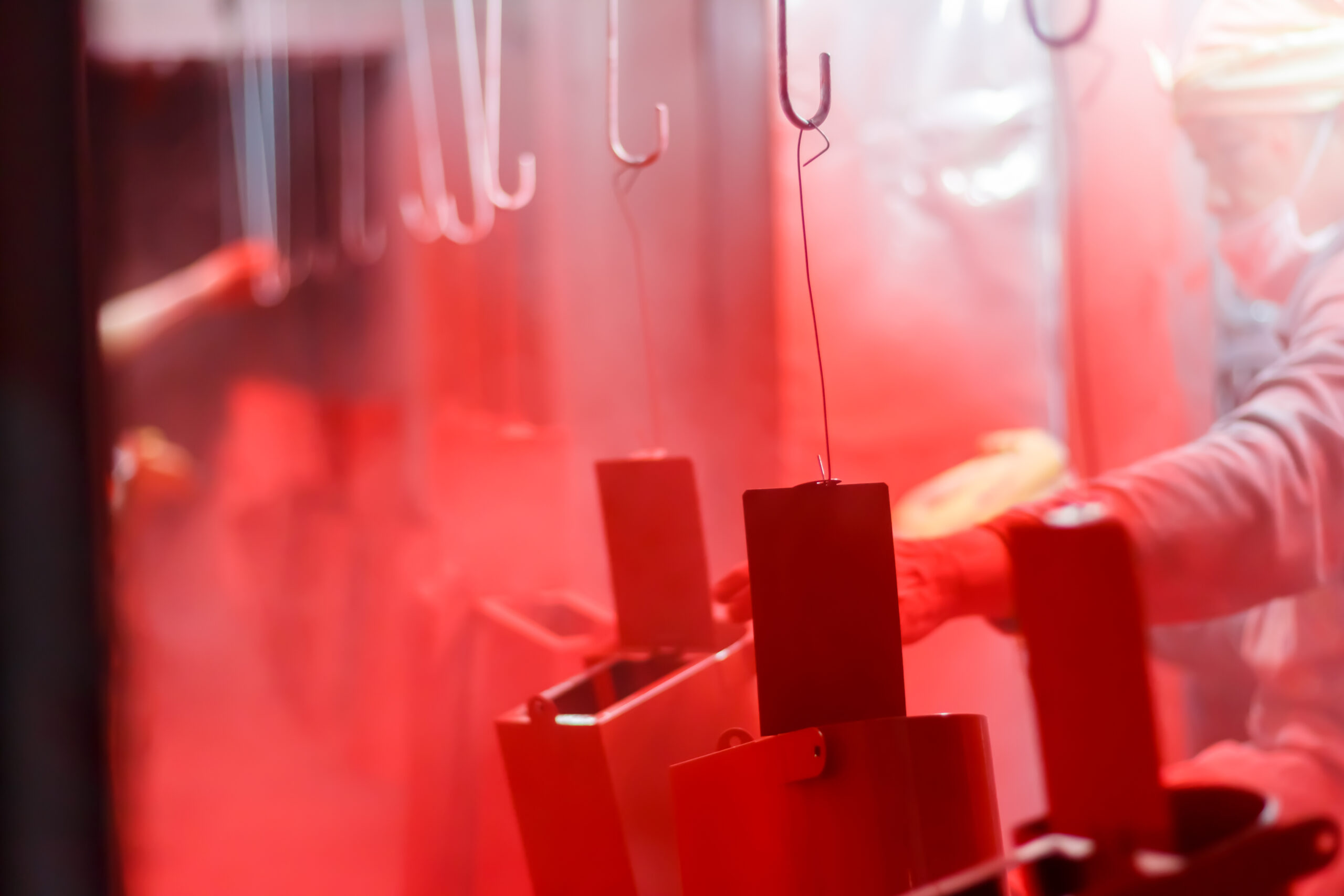

We provide comprehensive Coating Finish Tests to evaluate the quality, performance and characteristics of applied coatings on Metal Components and Products.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Coating Finish Testing?

Metal components and products can benefit from a wide range of coatings that serve as a shield against corrosion and provide protection. Coating Finish Testing involves evaluating the quality, performance, and characteristics of applied coatings on surfaces. The quality of the coating is of utmost importance as it prevents corrosion and ensures the longevity of the components.

This type of testing is essential for ensuring that coatings meet specified standards, adhere properly to the sample or material, and provide the desired protective and aesthetic properties. Coating options often range from Zinc Plating, Paint Systems, and Powder Coatings. These play a crucial role in safeguarding various components used across numerous industries and businesses. Whether it’s fasteners and metals used in subsea operations or automotive parts, coatings act as a protective barrier, shielding components from the harsh conditions they encounter during service.

Who we've partnered with

Let's talk about Coating Finish Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Why choose Coating Finish Testing?

By analysing the results of coating finish testing, you can gain valuable insights into whether the correct thickness has been applied to your product, and understanding if your product meets the required specifications or standards. At BES Group, we specialise in Coating Finish Testing for a wide range of industries.

Which products need Coat Finish Testing?

Whether it’s door and window furniture, automotive parts, white goods, or construction materials, we ensure that the pre-treatment chemicals and processes prior to painting or plating are thoroughly assessed.

Experts in Coat Finishing

Our expertise is not limited to in-house processing or process control; we also cater to manufacturers and suppliers of pre-treatment chemicals. With our accurate comparative data, we help our clients determine the best-performing products and showcase their capabilities.

The importance of Coating Finish

Choosing the appropriate metal coating depends on factors such as the required level of protection, the environment in which the metal will be used, cost considerations, and aesthetic preferences. Each coating option has its advantages and limitations, and the selection should align with the specific needs of the application.

Coating Finish Tests offered by BES Group

Various tests are conducted to assess the durability, adhesion, appearance, and functionality of coatings. The choice of tests depends on the type of coating, the intended application, and industry standards or specifications.

Coating Thickness Testing (coating meter)

Coating Thickness Tests are crucial quality control measure to ensure that applied coatings meet specified standards and provide the intended protective properties.

Coating Weight Mass

Coating Weight Mass Testing is a method used to measure the mass or weight of a coating applied to a substrate. This testing is crucial in industries where precise control over the amount of coating is essential for achieving desired performance characteristics.

Coating Thickness (Microscopical)

Our Metallurgy Department can analyse Coating Thickness Microscopically which will measure the thickness surrounding coated material.

Coating Adhesion Testing

Coating Adhesion Testing comes in many forms and is used to assess the coating adherence of the coated products on metallic substrate.We work to the following standards: BS EN ISO 2409, ASTM D1654 and ASTM B571

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

35,000 satisfied customers

A strong reputation for providing exceptional service.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

Bespoke solutions

We work closely with our customers to understand their specific needs and to develop customised solutions that meet their compliance requirements, ensuring that their exams are carried out smoothly and efficiently.

Frequently asked questions

What types of coatings do BES Group test?

There are many options available for applying protective layers to metal components or products, aiming to prevent corrosion damage and establish a safeguarding barrier.

- Zinc Plating

- Hot-Dip Galvanizing

- Anodizing

- Tin Plating

- Electroless Nickel Plating

- Chromium Plating

- Cadmium Plating

- Copper Plating

- Phosphating

- Paints and Powder Coatings:

- Thermal Spray Coatings

- Organic Coating Systems

Why is Coating Thickness Testing important?

This testing involves measuring the thickness of a coating on a substrate, and it is particularly important for applications where the coating’s thickness directly influences its performance.

Accurate coating thickness testing is essential to prevent issues such as inadequate protection due to insufficient thickness or problems related to excessive coating thickness, such as cracking or poor adhesion. The specific testing method chosen will depend on factors such as the type of coating, substrate material, and industry standards.

What are the key aspects of Coating Weight Mass Testing?

Coating Weight Mass Testing ensures that coatings provide the intended benefits, such as corrosion resistance, adhesion, and durability. The choice of testing method depends on factors such as the type of coating, substrate material, and industry requirements.

The coating weight mass test is mostly performed on flat sheet products of zinc plating and alloys, as set out in BS EN 10346:2015 for triple spot test or a single spot test, which gives our customers the results of the total coating mass of both sides of the product in g/m².

What does Coating Microscopic Testing involve?

Coating Thickness Microscopic Testing involves using a microscope to examine the cross-section of a coated sample to determine the thickness and characteristics of the coating. This method allows for a detailed analysis of the coating’s structure, including layer thickness, uniformity, adhesion to the substrate, and potential defects.

What are the benefits of Coating Thickness Microscopic Testing?

Coating thickness microscopic testing is particularly valuable for research and development, quality control, and troubleshooting coating-related issues. It allows for a detailed examination of coating properties that may not be apparent through other testing methods. The choice of microscopic technique depends on the specific requirements of the analysis and the available equipment.

We have two methods for performing these types of tests:

- If the coating on the metal is visible, we use a microscope to measure the thickness.

- If the coating is not visible or requires trace thickness measurements (where the thickness might be less than 1 micron or 1000th of a millimetre), we can use SEM Analysis to measure the coating

What is the importance of Coating Adhesion Testing?

Coating Adhesion Testing is a critical evaluation method used to assess the bond strength between a coating and the substrate. Adequate adhesion is essential for ensuring the coating’s durability, performance, and longevity. Various methods are employed to measure adhesion, and the choice of method depends on factors such as the type of coating, substrate material, and industry standards.

Using a scribing tool or knife, coating adhesion testing help our customers to determine whether the correct thickness has been applied for the products, and that they meet their required standards.

It’s important to note that the appropriateness of a particular adhesion testing method depends on factors such as the coating type, substrate material, and industry standards. The results of adhesion testing help ensure that coatings adhere securely to substrates and perform effectively in real-world conditions.

This can be used on painted or coated products on a metallic substrate and used in accordance with salt spray testing or humidity testing, or as received samples.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team