Lubrication Services

Oil Analysis

Maintain the serviceability of your machinery and asset portfolio with our Oil Analysis services. We help clients improve reliability, enhance safety, and reduce the environmental impact of assets and equipment.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Oil Analysis?

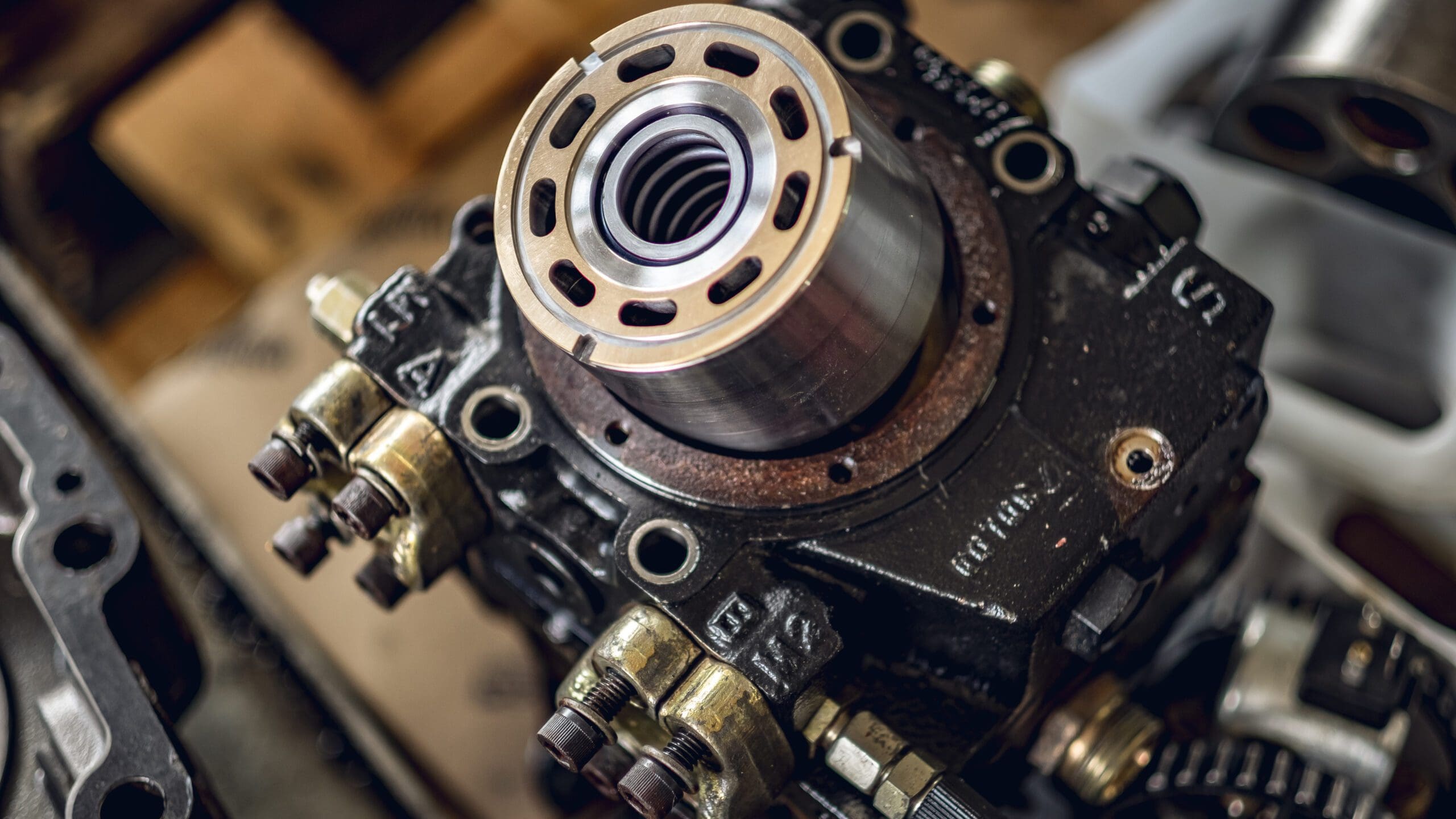

Oil Analysis is a solution that will help you increase your equipment uptime and reduce maintenance costs. Focusing on asset and machinery health, we can help to increase uptime, reduce maintenance costs, and make sure your equipment is still suitable for further servicing with our lubrication services.

We offer a comprehensive oil analysis service, aimed at optimising the reliability and performance of your industrial equipment. Through advanced testing and analysis techniques, we help you monitor the condition of your lubricating oils, identify potential wear issues, and implement proactive maintenance strategies. With our oil analysis service, you can improve reliability, enhance safety, and reduce the environmental impact of your assets and equipment.

Who we've partnered with...

The benefits of our Oil Analysis service

Identify potential failure modes early

Critical fluid analysis allows for the detection of subtle changes which will enable you to identify potential issues before they escalate into major failures.

Identify housekeeping issues

These often go un-noticed and include things such as: poor lubrication practices, filter and breather management and incorrect grade deployment, which are significant contributors to limiting machinery life.

Optimise maintenance practices

By understanding the health of your lubricants, you can optimise maintenance activities, avoiding unnecessary downtime and reducing maintenance costs.

Maintain equipment lifespan

By properly managing lubricating oils, we can help to ensure than you achieve the expected lifespan of your equipment while avoiding the deterioration that will occur if machines are not cared for appropriately.

Achieve optimal reliability

By proactively monitoring fluid condition, you will be able to optimise the reliability of your machinery, eliminate unexpected breakdowns and improve overall operational efficiency.

Let's talk about Oil Analysis

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Sample types and test suites BES Group offers

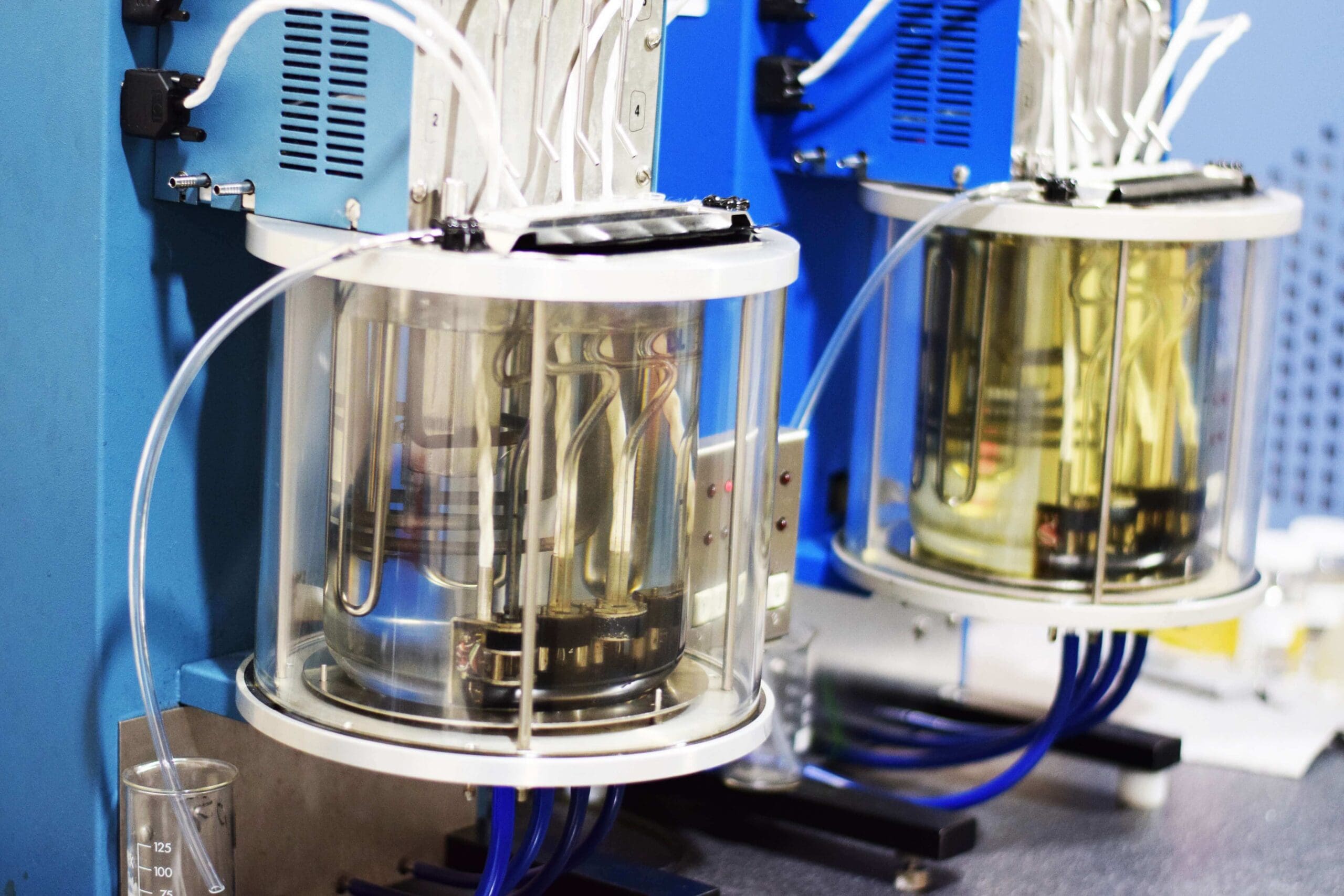

At BES Group, our oil laboratory forms part of a focused and passionate group of reliability services, provided by experienced and qualified engineers and technicians. For us, it is about the asset and the assets’ needs. We can deploy the right approach for all situations where oil analysis offers both a planned predictive and proactive maintenance support strategy.

| Sample Types | Test Suites |

|---|---|

| Chiller | Visual Inspection, Ferrous Wear, Water/CKF, Particle Count, TAN. |

| Compressor | Visual Inspection, Ferrous Wear, Water/VKF, Viscosity at 40 Deg C, TAN |

| Coolant | Visual Inspection, Ferrous Wear, ICP, PH, %Glycol, Density, Conductivity |

| Engine | Visual Inspection, Ferrous Wear, ICP Water/VKF, Viscosity at 40/100 Deg C, TBN, TAN, TIM and FTIR |

| Gas Engine | Visual Inspection, Ferrous Wear, ICP, Water/VKF, Viscosity and 40/100 Deg C, Viscosity Index, TBN, TAN, TIM and FTIR |

| Diesel | EN590/BS2859 Specification Testing Visual Inspection, Ferrous Wear, ICP, Water/CKF, Particle Count, Bacteria Analysis |

| Gearbox | Visual Inspection, Ferrous Wear, Water/VKF, Viscosity at 40 Deg C |

| Grease | Visual Inspection, Ferrous Wear, ICP, Water/CKF |

| Hydraulic | Visual Inspection, Ferrous Wear, ICP, Water/VKF, Particle Count, TAN |

| Turbine | Visual Inspection, Ferrous Wear, ICP, Water/CKF, Viscosity at 40 Deg C, TAN, FTIR, RPVOT, RULER, MPC Varnish |

| Transformer Oil Suite(s) | On Request |

| Forensic Analysis | Wear Debris, Filter Debris Analysis, Ferrography |

| Extra Tests | Flashpoint : Seta/PMCC/COC, RULER, RPVOT, MPC, Foaming, Water Separability |

Oil Analysis Services from BES Group

Explore Oil Analysis Service- Fluid Property Analysis

- Wear Particle Analysis

- Wear and Contamination Analysis

- Contamination Analysis

- Lubricant Condition Monitoring

- Trending and Deeper Analysis

We conduct detailed tests to assess many critical fluid features such as viscosity, acidity, water content, cleanliness, additive retention, performance deterioration and oxidation levels of your lubricating oils. This analysis helps to identify potential oil degradation and contamination issues, but also provide assurances of good management and ongoing reliability.

In the event of unexpected wear, our experts examine oil samples using specialised equipment to identify and analyse wear particles. This analysis of shape, size and quantity, known as morphology, assists in diagnosing wear patterns, wear rates and risks and allows us to identify the root causes, in order to assist you with planning targeted maintenance actions.

As part of the routine suite of tests we measure oil condition, but we also maintain a critical eye on the levels of wear and contamination that may exist. As wear is a normal but manageable aspect of system operation, we look at the materials associated with wear and contaminants and provide an assessment of the current state at every analysis.

We assess samples for the presence of contaminants such as dirt, fuel, coolant, and metal fines. Detecting contaminants early on helps prevent equipment damage and helps you to target improvements in overall system cleanliness.

Our oil analysis services include monitoring the condition of lubricants over time, tracking changes in their properties and identifying trends that may indicate abnormal conditions or impending failures.

With Asset 365 – our online reporting portal, you have access to every report and can generate your own assessments using any test parameters. You will have access to all test data and can build reports from raw data to review your results in any way you like.

-

Fluid Property Analysis

We conduct detailed tests to assess many critical fluid features such as viscosity, acidity, water content, cleanliness, additive retention, performance deterioration and oxidation levels of your lubricating oils. This analysis helps to identify potential oil degradation and contamination issues, but also provide assurances of good management and ongoing reliability.

-

Wear Particle Analysis

In the event of unexpected wear, our experts examine oil samples using specialised equipment to identify and analyse wear particles. This analysis of shape, size and quantity, known as morphology, assists in diagnosing wear patterns, wear rates and risks and allows us to identify the root causes, in order to assist you with planning targeted maintenance actions.

-

Wear and Contamination Analysis

As part of the routine suite of tests we measure oil condition, but we also maintain a critical eye on the levels of wear and contamination that may exist. As wear is a normal but manageable aspect of system operation, we look at the materials associated with wear and contaminants and provide an assessment of the current state at every analysis.

-

Contamination Analysis

We assess samples for the presence of contaminants such as dirt, fuel, coolant, and metal fines. Detecting contaminants early on helps prevent equipment damage and helps you to target improvements in overall system cleanliness.

-

Lubricant Condition Monitoring

Our oil analysis services include monitoring the condition of lubricants over time, tracking changes in their properties and identifying trends that may indicate abnormal conditions or impending failures.

-

Trending and Deeper Analysis

With Asset 365 – our online reporting portal, you have access to every report and can generate your own assessments using any test parameters. You will have access to all test data and can build reports from raw data to review your results in any way you like.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

Training centre & academies

Our very own internal training academies, ensures high standard.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Rail

Explore sector

Power and Utilities

Explore sector

Renewables

Explore sector

Retail

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team