Asset Reliability

Lubrication Services

We offer comprehensive Lubricant analysis to help you get the most out of your industrial equipment, whether through routine assessment or implementing a Lubrication management plan.

Explore Lubrication Services

Interested? Let’s talk.

Send us an enquiry

Who we’ve partnered with...

What are Lubrication Services at BES Group?

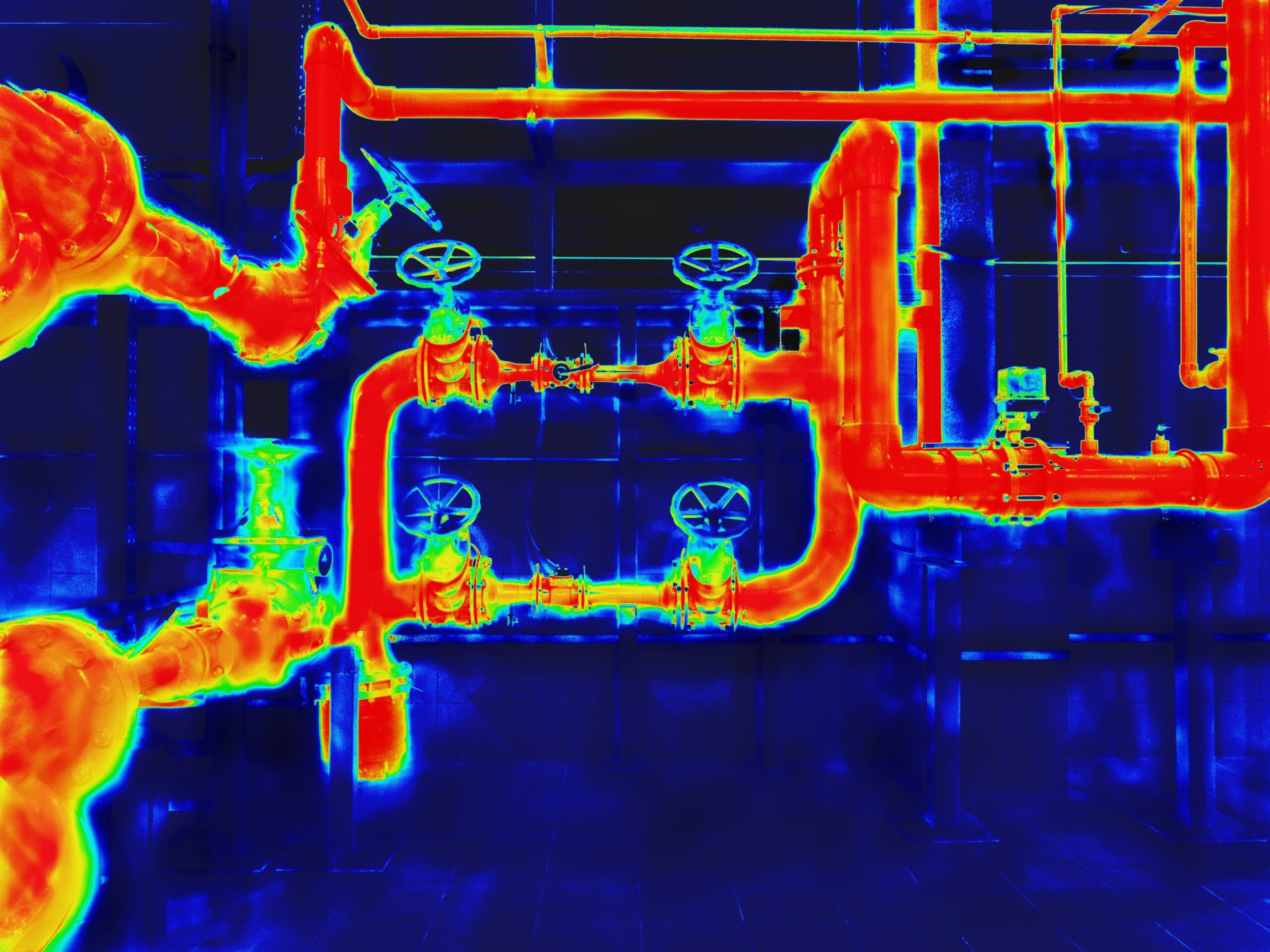

Our Lubricant analysis services include various testing methods to gain insights into your machinery condition.

Keep your operations running smoothly with BES Group’s Lubrication Management Services. We’ll delve deep into the health and performance of your equipment to help you manage maintenance schedules and increase machinery efficiency. With independent Lubrication testing labs, specialist analysts, and quick turnaround on sample results, you can rely on our expert Lubrication Services. Boost the performance and reliability of your industrial equipment for years to come.

Let's talk about Lubrication Services

Send us an enquiry

Not seeing what you expected?

Try using our search

Explore what our clients say

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Rail

Explore sector

Renewables

Explore sector

Retail

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Lubrication Services at BES Group

Explore all sub-services- Why choose BES Group Lubrication Services?

- Key benefits of Lubrication Services

Our Lubrication Management Services consider every aspect of your machinery and industry challenges.

We’re proud to have independent lubricant testing labs, so we handle every aspect of samples, including sampling, analysis, and reporting. Our quick turnaround means your lubricant analysis report is available without delay and easily accessible from your online platform.

We also provide Reliability Consulting as part of our Lubrication Services. Our trained lubricant experts will discuss the results and help you understand what action you need to take. Our relationship with oil management system suppliers means we can assist you with removing particulates or water if they’re identified during the Oil Analysis process.

Improved sustainability

Increase sustainability and reduce carbon emissions by optimising machinery maintenance.

Safety compliance

Prevent equipment malfunctions and failures that could lead to accidents by maintaining lubrication efficiency.

Reduced maintenance

Keep your machinery in check and reduce unnecessary maintenance or downtime by identifying hazards before they cause issues.

Prolonged equipment lifespan

Protect your equipment from wear, corrosion, contamination, and costly failures by maintaining the health and safety of your machinery.

Increased productivity

Maintain optimal equipment performance by detecting any health or operational challenges before they become problematic.

-

Why choose BES Group Lubrication Services?

Our Lubrication Management Services consider every aspect of your machinery and industry challenges.

We’re proud to have independent lubricant testing labs, so we handle every aspect of samples, including sampling, analysis, and reporting. Our quick turnaround means your lubricant analysis report is available without delay and easily accessible from your online platform.

We also provide Reliability Consulting as part of our Lubrication Services. Our trained lubricant experts will discuss the results and help you understand what action you need to take. Our relationship with oil management system suppliers means we can assist you with removing particulates or water if they’re identified during the Oil Analysis process.

-

Key benefits of Lubrication Services

Improved sustainability

Increase sustainability and reduce carbon emissions by optimising machinery maintenance.

Safety compliance

Prevent equipment malfunctions and failures that could lead to accidents by maintaining lubrication efficiency.

Reduced maintenance

Keep your machinery in check and reduce unnecessary maintenance or downtime by identifying hazards before they cause issues.

Prolonged equipment lifespan

Protect your equipment from wear, corrosion, contamination, and costly failures by maintaining the health and safety of your machinery.

Increased productivity

Maintain optimal equipment performance by detecting any health or operational challenges before they become problematic.

Lubrication Services FAQs

How can I improve Lubrication management at my premises?

There are many ways to improve lubrication management, including the following:

- Develop a lubrication plan: Create a detailed schedule outlining lubricant types and application frequency.

- Use the right lubricant: Choose lubricants tailored to the specific requirements of your machinery.

- Lubricate regularly: Apply lubricants at consistent intervals to maintain optimal performance.

- Follow the correct procedures: Adhere to proper application techniques to avoid lubrication-related issues.

- Inspect regularly: Regularly check lubrication levels and condition to prevent equipment failures.

What are industrial Lubricants?

Industrial lubricants are substances applied to machinery and equipment that reduce friction between parts.

They’re used to prevent wear and tear, protect against rust and corrosion, and ensure machines operate efficiently under various temperature and pressure conditions.

Some examples of industrial lubricants include motor oils, grease, hydraulic fluids, and gear oils. These can be tailored to specific applications such as automotive engines, bearings, hydraulics, and industrial gears.

When should I consider Lubrication Maintenance Services?

You should incorporate Lubrication Maintenance Services into your overall lubrication management plan.

This should outline how frequently you will test and analyse machinery, helping you to take a preventative approach and detect problems before they arise.

However, you should also do lubrication maintenance if you notice issues with your machinery. Warning signs can include:

- Increased vibration

- Excessive noise

- Increased heat

- Leaks

- Contamination

- Early bearing failure

- Reduced efficiency

- Increased maintenance costs

- Safety hazards

What can happen if Lubrication is not properly maintained?

Improper lubrication can have drastic consequences, risking your equipment’s safety and performance. It can also lead to unplanned downtime, lost productivity, and unnecessary costs, affecting operational efficiency.

Some of the most common consequences include:

- Premature wear and tear: Without adequate lubrication, machinery is at risk of increased friction, leading to additional wear and tear.

- Reduced efficiency: Friction forces machinery to work harder, consuming more energy and decreasing overall efficiency.

- Increased noise and vibration: Excessive wear and friction can cause machinery to operate louder and with more vibrations.

- Leaks: Inadequate lubrication can break seals, resulting in oil or lubricant leaks. This could cause slip hazards and contamination issues.

- Contamination: Contaminants can leak through systems if seals are not secure, creating safety and efficiency hazards.

- Fires: Lubricant leaks can increase the risk of fires, especially near hot surfaces or electrical components.

- Breakdowns: Inadequate lubrication can cause machinery to break down, leading to costly repairs or replacements and unplanned downtime.

How long does a Lubricant Service take?

Ultimately, it depends on the type and volume of sample, the machinery being tested, and the type of service.

At our lubricant analysis laboratory, the average turnaround time is between 24 hours and 5 days, depending on the volume of samples taken:

- Gearbox samples: 24 hours

- Chiller samples: 24 hours

- Engine samples: 24 hours

- Hydraulic samples: 24 hours

- Fuel samples: 5 days

- Coolant samples: 24 hours

- Grease samples: 24 hours

What's included in a BES Group sample kit?

Our sample kits include everything needed to assess your machinery. Every sample kit is tailored to your needs, so the tickets and labels will vary depending on the sample type you’ve requested.

Our kits include the following: Sample bottle Sample label Sample info ticket Leak-proof bag Tubing Pre-paid returns envelope

Which industries use Lubricants?

Lubricants are used in many industries to help maintain machinery performance. These include:

- Marine: Lubricants are used in ship engines and deck equipment to prevent corrosion and wear caused by saltwater and harsh marine environments.

- Rail: Lubricants are used for in gearboxes to reduce friction in wheel bearings and suspensions.

- Production: Lubricants prevent equipment malfunction and wear, ensuring continuous and efficient operation.

- Aviation: Aviation lubricants are crucial for asset performance and safety. They manage wear and particulate in airplane hydraulic systems and components.

- Industrial: Lubricants are used in industrial machinery to reduce wear and tear, prevent rust, and keep them running smoothly.

- Manufacturing: Lubricants are used to ensure that production equipment runs smoothly and efficiently.

- Transport: Lubricants help maintain vehicles like trucks and buses, ensuring engines run efficiently and reducing the likelihood of breakdowns.

- Heavy engineering: Lubricants are used for large machinery and cranes to handle heavy loads and operate in extreme environments without failure.

- Recycling: Lubricants are used to maintain machinery, especially those that process recyclable materials. This helps to prevent equipment failures due to contamination or heavy use.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Five Benefits Of Taking A Vibration Analysis Course For You And Your Business

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team