Condition Monitoring

Video Deflection and ODS

Elevate your reliability standards through our Video Deflection and ODS services. At BES Group, we bring clarity to complex issues, ensuring that your equipment and structures operate at peak efficiency while prioritising safety.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Video Deflection and ODS?

Video Deflection captures real-time visual data, providing a comprehensive understanding of structural behaviour, while ODS dives deep into dynamic analyses, pinpointing the root causes of issues. Whether addressing machinery performance or structural integrity, our services empower you to proactively enhance operations.

In the realm of machinery and structures, our team at BES Group can provide transformative solutions with Video Deflection and Optical Deflection System (ODS) services.

If you’re suffering from challenges with your equipment such as vibration, misalignment, looseness, or structural defects, our advanced services can be the key to unlocking enhanced reliability, efficiency, and safety. At BES Group, our expert Reliability Engineers will deliver our industry-leading Video Deflection and ODS services to troubleshoot and confirm structural issues, providing visualised solutions for optimal reliability and structural integrity, all presented in clear and concise reporting

Who we've partnered with...

Key benefits of Video Deflection and ODS

Non-destructive

Video deflection and ODS are Non-destructive Testing (NDT) methods that do not damage the material being tested.

Versatile

Video deflection and ODS are versatile for inspecting a variety of materials and components across multiple industries.

Sensitive

Video Deflection and ODS are sensitive to small defects, making them ideal for inspecting composites and plastics.

Let's talk about Video Deflection and ODS

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How can our Video Deflection and ODS Services help you?

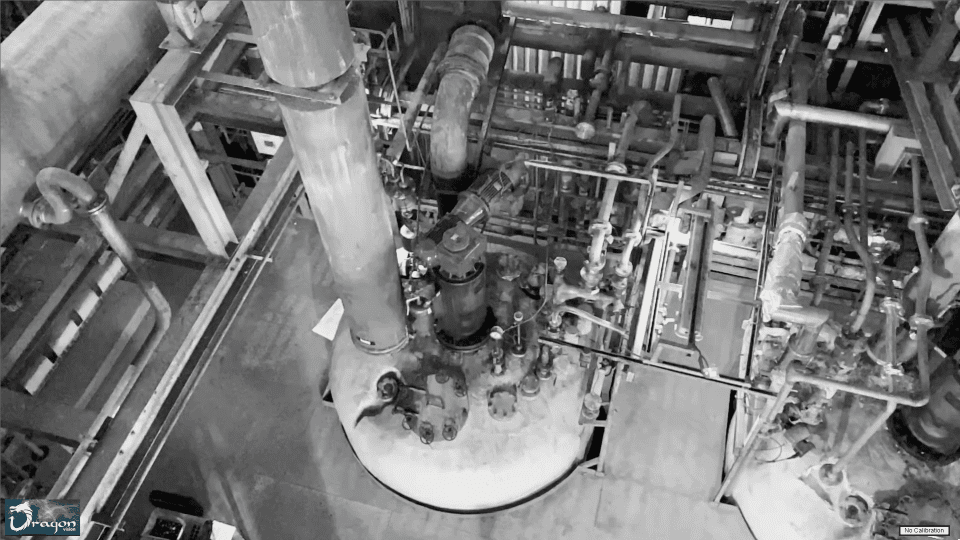

Primarily used as a troubleshooting and confirmation tool, the power of the combined Video Deflection and ODS services provides a visualised insight into the operational characteristics of an asset or structure. For example, where additional strengthening is required, it provides a visual indication of the exact location of the node and anti-node points to ensure structural integrity is maintained and structural adjustments have the desired effect on the structure.

Our Asset Reliability Engineers

We have a large team of Reliability Engineers who have expertise in Video Deflection and ODS, meaning that you can rest assured that we will be able to help you determine the cause of any issues you may be facing with your equipment or assets, and to provide you with detailed reports and recommended actions.

Our Expertise

We always strive to make Vibration Analysis and Condition-based Maintenance (CBM) technology applications easy to understand. While our trained and accredited engineers and analysts use advanced techniques, we ensure that our reporting recommendations are clear, concise, accurate, and realistic.

What kind of failures can be detected using Video Deflection and ODS?

Video deflection and ODS technology is a powerful tool for detecting and confirming a wide range of failures, particularly those related to low frequencies. This is because it allows for the visualisation and analysis of vibration patterns, which can often provide valuable insights into potential issues. Some of the specific types of failures that can be detected include:

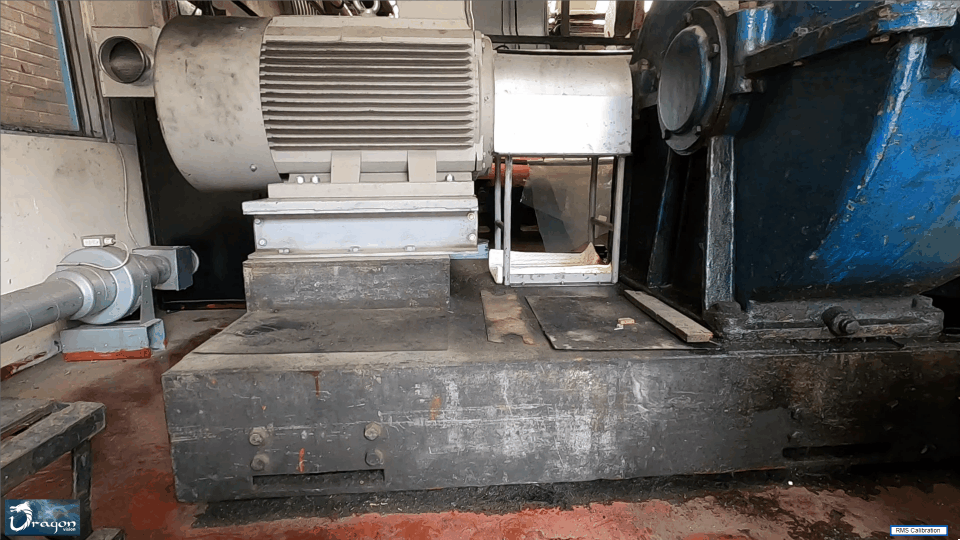

Imbalance and misalignment

These are common causes of vibration, and video deflection and ODS can help to identify the exact position and severity of the imbalance or misalignment.

Structural/mechanical looseness

Looseness in bearings, couplings, or other components can also cause vibration, and video deflection and ODS can help to pinpoint the source of the looseness.

Bent shaft

A bent shaft can cause a characteristic vibration pattern that can be easily identified using video deflection and ODS.

Eccentricity

Eccentricity refers to an object that is not centred on its axis. This can cause vibration, and video deflection and ODS can help to quantify the amount of eccentricity.

Resonance

Resonance occurs when a machine or structure vibrates at its natural frequency. This can lead to excessive vibration and potential damage.

Our Video Deflection and ODS process

Speak to us about the processLearn more about how BES Group will implement Video Deflection and ODS to transform your business

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

Training centre & academies

Our very own internal training academies, ensures high standard.

Frequently asked questions

What are the advantages of Video Deflection and ODS over other NDT methods?

There are several advantages of choosing Video Deflection and ODS in favour over other NDT methods, here are some examples:

- Versatile: They can be used across most industries to inspect a variety of materials and components.

- Sensitive: They can detect the smallest defects, making them ideal to inspect materials that are prone to small defects, such as composites and plastics.

- Fast and Efficient: Larges areas can be inspected quickly and efficiently making them a good option for inspecting large components or structures.

When would we use video deflection technology?

Video deflection technology is often used in conjunction with traditional vibration monitoring techniques. This is because it can provide valuable additional information, such as the visual representation of vibration patterns.

Here are some specific situations in which video deflection technology may be used:

- Troubleshooting vibration problems: Video deflection can often help to diagnose the source of vibration problems more quickly and accurately.

- Confirming vibration measurements: Video deflection can help to confirm vibration measurements made using other methods, such as accelerometers.

- Monitoring structural health: Video deflection can be used to monitor the health of structures over time, helping to identify potential problems early on.

What faults can we detect with Video Deflection and ODS technology?

Video Deflection and ODS technology can detect a wide range of faults, including:

- Structural weaknesses and excessive directional compliance: These can lead to excessive vibration and potential damage.

- Structural resonance: Resonance can cause excessive vibration and potential damage.

- Critical speed resonance: Critical speed resonance occurs when the rotating speed of a machine coincides with one of its natural frequencies. This can cause catastrophic failure.

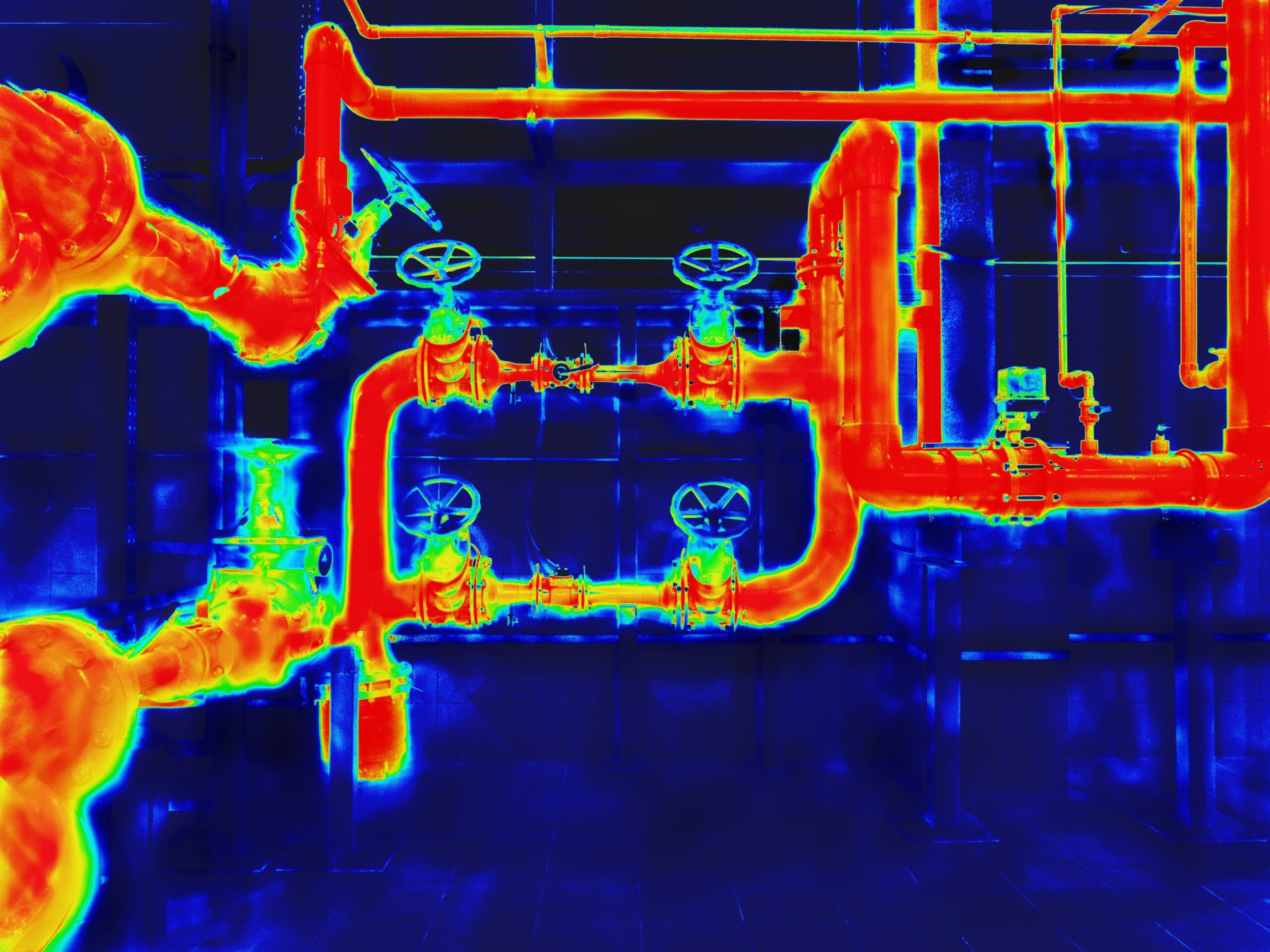

- Pipe strain issues: Excessive strain in pipes can lead to leaks or ruptures.

- Severe misalignment: Misalignment can cause excessive vibration and potential damage.

- Bent shafts: Bent shafts can lead to excessive vibration and potential damage.

- Mechanical looseness: Looseness in bearings, couplings, or other components can cause excessive vibration and potential damage.

- Severe unbalance: Unbalance can cause excessive vibration and potential damage.

- Transient vibration issues: Transient vibration can occur due to sudden changes in load or speed. Video deflection can help to identify the source of transient vibration problems.

Why should we use Video Deflection and ODS technology?

Video Deflection and ODS technology is a valuable asset management tool for several reasons.

It can:

- Reduce downtime: By detecting and diagnosing problems early on, video deflection and ODS can help to reduce downtime and prevent costly repairs.

- Extend the life of assets: By identifying and addressing potential problems, video deflection and ODS can extend the life of assets and reduce the need for replacement.

- Improve safety: By identifying and addressing potential safety hazards, video deflection and ODS can help to improve safety and reduce the risk of accidents.

- Increase efficiency: By providing valuable insights into asset performance, video deflection and ODS can help to improve efficiency and reduce operating costs.

If you are concerned about the health of your assets, video deflection and ODS technology can be a valuable tool for preventing costly failures and improving the overall performance of your operations.

Let's talk about Video Deflection and ODS

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Power and Utilities

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Rail

Explore sector

Renewables

Explore sector

Retail

Explore sector

Transport, Logistics and Distribution Centres

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team