Mechanical Testing

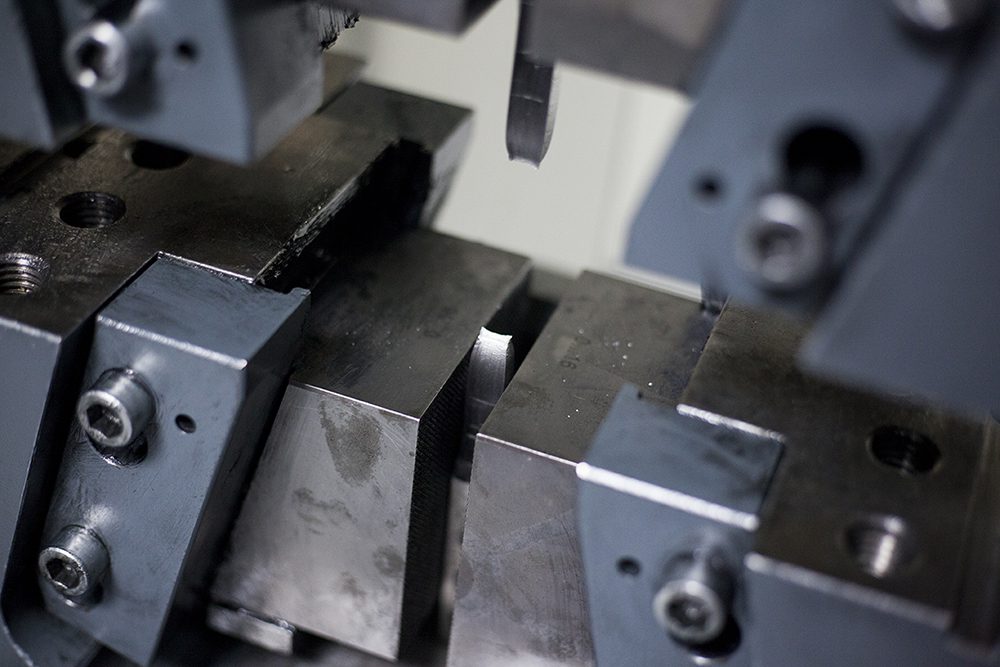

Tensile Testing Services

Tensile testing is a fundamental method for understanding how materials respond to applied forces and provides crucial insights into their mechanical properties.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Tensile Testing?

Tensile testing is used to determine the (UTS) Ultimate tensile strength, Ultimate Yield Strength, & Young’s Modulus.

Tensile Testing measures how materials respond when they are pulled apart, by applying a controlled force to a sample until it breaks. We can then identify key properties such as tensile strength, metal elongation, tensile elasticity, and plastic deformation.

At BES Group, we provide comprehensive Tensile Strength Testing to help you understand your material’s performance. Our tests offer valuable insights into strength and durability, helping to verify quality standards and prevent potential material failures.

Materials we test:

- Metals – alloys, steels, and other metal products

- Fasteners – bolts, screws, and nuts

- Forgings and Castings

- Rebar

- Plastics

- Custom products – dog clips, luggage straps, industrial chains and more

Who we’ve partnered with...

Key benefits of Tensile Testing

Quality assurance

A Tensile Test ensures material quality, consistency, and compliance with industry standards.

Material selection

Tensile Stress Test data helps with material selection, ensuring strength and ductility for specific applications.

Product design and optimisation

Tensile strength test data supports product design that meet performance requirements and prevent failures.

Research and development

Tensile Test yield strength data supports innovation with new products and materials.

Let's talk about Tensile Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

We are committed to providing you with accurate and reliable Tensile Testing services, to ensure your materials meet the highest standards for quality, safety, and performance.

Technologists in our lab will work with you to understand your specific needs and tailor our testing approach to provide valuable insights into your materials’ properties. Our goal is to enhance the safety of your products, giving you confidence in their performance.

Whether you’re in aerospace, construction, manufacturing, or any other industry, we help identify potential weaknesses and ensure your materials are ready for critical applications.

Our Testing Capabilities

Our testing machines allow us to test to a number of standards for Tensile Testing, including:

- BS EN 2002-1

- BS EN ISO 6892-1 Methods A & B

- BS EN ISO 6892-2 Method A ASTM E21

- ASTM E8/8M

- ASTM A370

Elevated Temperature Tensile Testing

Our High Temperature Tensile Testing assesses how materials behave when exposed to high temperatures. By simulating these extreme conditions, we can evaluate key properties like creep resistance and thermal expansion.

Assessing Critical Aerospace Components

Hot Tensile Testing is essential in industries like aerospace, where it’s used to analyse the behaviour of high-strength metals such as aluminium alloys, titanium alloys, and nickel-based superalloys.

Our testing helps engineers make informed decisions on material selection and design, ensuring the safety, reliability, and performance of aerospace components and structures in real-world conditions.

Our Range of Temperatures for Tensile Testing

- Routine Tensile (ambient temperature, forces from 2kN to 600kN)

- Elevated Tensile (temperature from ambient to 600°C, forces from 2kN to 100kN)

Our Tensile Testing Procedure

Speak to us about the processOur process ensures accurate testing through assessment, preparation, analysis, and reporting to meet your material needs.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What standards are applied to Tensile Testing?

We can test samples for Tensile Testing at ambient temperature, with forces from 2kN up to 600kN, or Elevated Tensile (temperature from ambient to 600°C, forces from 2kN to 100kN).

We work to several standards for Tensile Testing, including:

- BS EN ISO 6892-1 Methods A & B

- ASTM E8/8M

- ASTM A370

- BS EN 2002-1

- ASTM B557/B557M

- ASTM E21

What can Tensile Testing measure?

Tensile Testing allows us to measure various parameters such as:

- (UTS) Ultimate Tensile Strength

- Yield Strength

- Metal elongation

- Plastic deformation

- Young’s Modulus

What size of material do you need?

For general tensile testing of components or bar we will require a minimum 13mm square or diameter of material x 80mm long, but we can accommodate samples as small as 55mm in length.

For flat/sheet materials we ideally need a minimum of 10mm width x 70mm long.

For elevated tensile testing on round material, we would need 13mm x 70mm and 28mm x 200mm for flat material.

How long does a Tensile Test take?

Turnaround is generally 3 working days and 5 working days for elevated tensile testing from receipt of samples and a valid purchase order.

What does a Tensile Testing lab report include?

Our tensile testing report typically includes:

- A test summary: Type of testing, test specifications and test standards to be followed.

- Unique reference number: Each sample piece is given its own unique number for testing.

- Specimen information: Material type, dimensions and gauge length.

- Pass or Fail: Details on if the sample has passed or failed the criteria.

How many types of Tensile Tests are there?

There are several types of Tensile Testing. We offer two main methods:

- Uniaxial Tensile Test: The most common tensile test, where a specimen is pulled in one direction.

- High Temperature Tensile test: Performed at elevated temperatures to assess material properties under heat.

What is the purpose of Tensile Testing?

The purpose of Tensile Testing is to determine a material’s mechanical properties such as strength, ductility, elasticity, and toughness. It helps engineers assess how a material or component will behave when it is stretched or pulled by other forces.

What is the importance of Tensile Testing?

Tensile Testing is crucial because it provides essential data on key properties for materials such as yield strength, ultimate tensile strength (UTS), and elongation, which as critical for ensuring materials perform safely and reliably under stress.

Let's talk about Tensile Testing

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team