Hardness Testing

Vickers Hardness Testing

Vickers hardness testing precisely measures a material's resistance to deformation, aiding in quality control and material selection across various industries.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Vickers Hardness Testing?

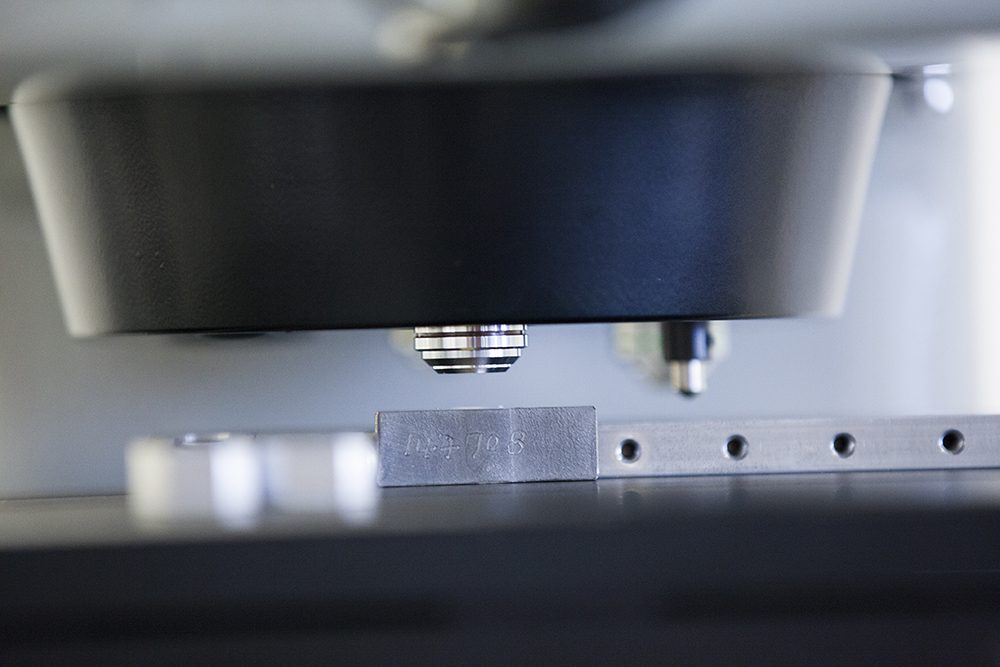

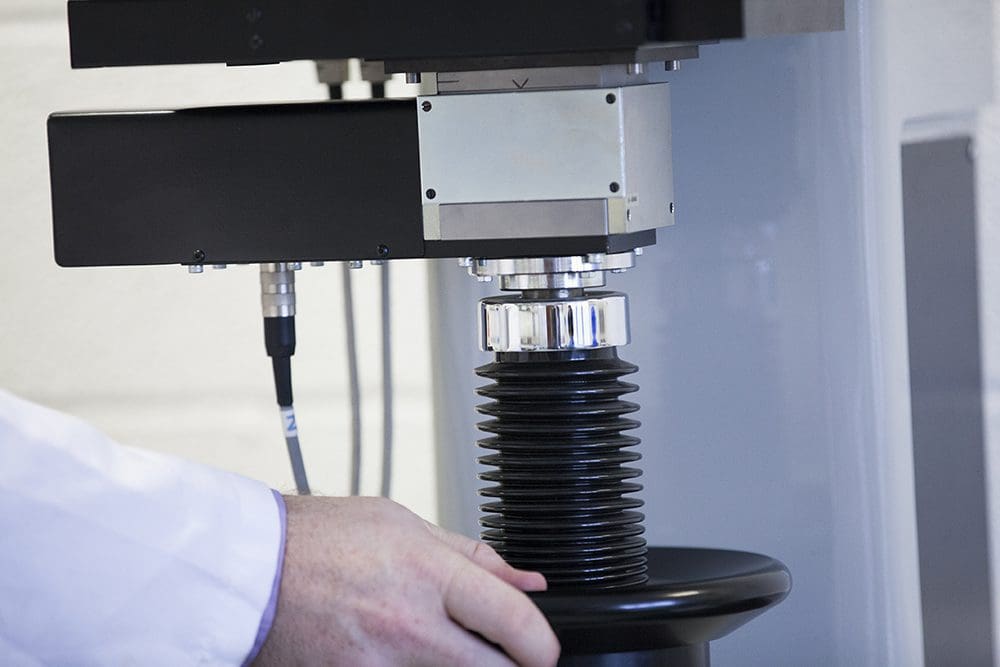

The Vickers Hardness Test measures a material’s resistance to plastic deformation by pressing a diamond pyramid-shaped indenter into its surface and analysing the resulting indentation.

This versatile method is applicable to a wide range of materials, including metals and alloys, and supports both macro and micro hardness testing. The Vickers Test plays a crucial role in quality control, material research, and engineering applications by evaluating a material’s resistance to deformation and wear. Its broad hardness scale makes it suitable for materials with varying hardness levels.

Due to its precision and reliability, Vickers Hardness Testing is widely used in industries such as manufacturing, aerospace, automotive, and materials science.

Who we've partnered with...

Key benefits

Versatility Across Materials

Applicable to a wide range of materials, including metals, alloys, ceramics, and thin coatings, making it ideal for diverse industrial and research applications.

Precision and Accuracy

Provides highly accurate and reliable hardness measurements, essential for quality control, material research, and compliance with industry standards.

Broad Hardness Range

Covers a wide spectrum of hardness values, from soft to extremely hard materials, ensuring suitability for various testing requirements.

Small Sample Testing

Capable of testing small components, thin sections, and delicate materials using lighter loads without compromising accuracy.

Let's talk about Vickers Hardness Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

We collaborate closely with clients to understand their specific testing needs, ensuring accurate and reliable results. Our team provides detailed reports and insights to support your quality control and metal selection processes.

We offer flexibility in our hardness testing services.

Whether you require Vickers Hardness Testing as a standalone service to evaluate metal hardness or as part of a comprehensive analysis, we’ve got you covered.

For a deeper understanding of your metals, we can combine Hardness Testing with full Mechanical Testing (e.g. Tensile and Impact testing) and Chemical Analysis. This integrated approach provides a complete picture of your metal’s properties, ensuring quality, reliability, and compliance with industry standards.

Our process

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What Vickers Hardness Testing specifications do you work to?

We work to the following standards:

- BS EN ISO 6507-1:2018 (HV1, HV5, HV10)

- ASTM E92-17 (HV1, HV5, HV10)

- Low force Vickers Hardness tests (HV0.3, 0.5, and 1)

What materials can be tested with Vickers Hardness Testing?

The Vickers Hardness Test is known for its ability to provide precise and accurate hardness measurements, making it suitable for a wide range of materials, including metals, ceramics, and some polymers.

Vickers Hardness Testing is particularly useful for softer materials and thin sections.

How does Vickers Hardness Testing differ from other methods?

Unlike methods like Rockwell or Brinell, the Vickers test uses a diamond pyramid indenter and is applicable to all materials, regardless of hardness. It also provides a continuous hardness scale, making it versatile for various applications.

Why is Vickers Hardness Testing important?

It provides precise measurements of material hardness, essential for quality control, material selection, and ensuring components meet specific mechanical property requirements.

Let's talk about Vickers Hardness Testing

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team