Hardness Testing

Brinell Hardness Testing

The Brinell technique is considered one of the oldest methods for measuring hardness and is especially useful for analysing forgings, castings, and larger, rough samples of materials.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Brinell Hardness Testing?

Brinell Hardness Testing is most commonly used to test the hardness of bulk metal.

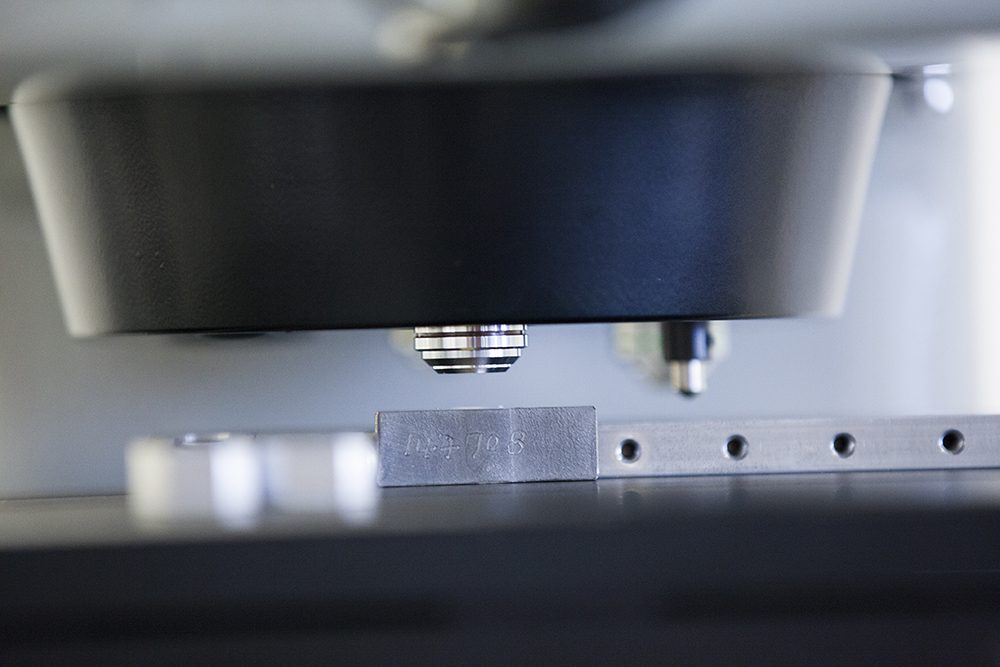

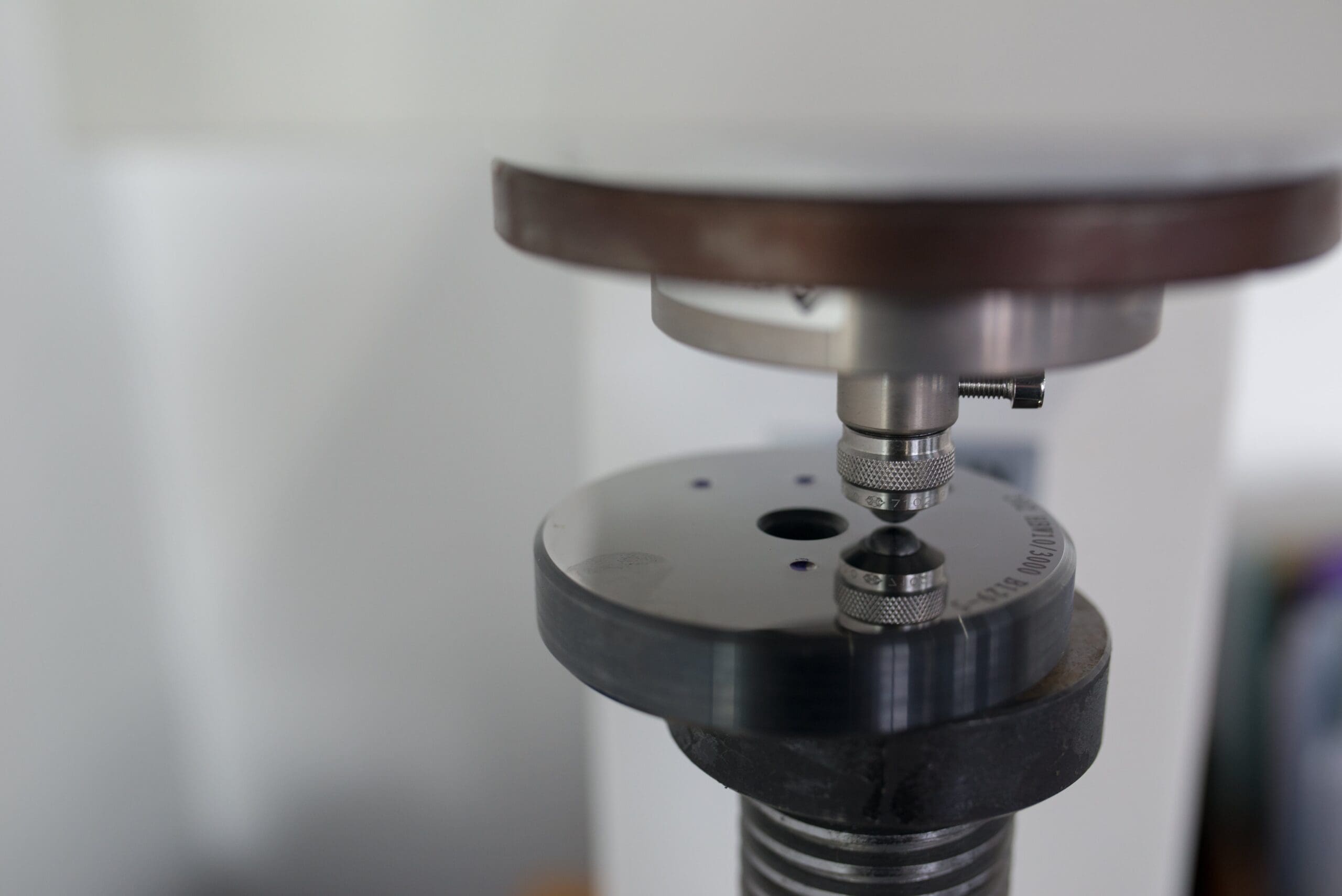

The Brinell Hardness Test is known for its wider indentation that covers a larger surface area, providing a more precise measurement of the material’s hardness. This test creates a deeper and wider indentation, allowing for a better assessment of the average hardness across a larger surface area compared to other hardness tests.

Materials such as non-ferrous metals, pre-heat treated steel, forgings, and castings are examples of those that stand to gain valuable insights through Brinell Hardness Testing.

Who we've partnered with...

Key benefits

Versatility with Larger Samples

Brinell Testing is ideal for assessing larger and coarser materials, such as forgings and castings, making it perfect for industries where these types of samples are common.

Comprehensive Hardness Measurement

The test provides an average hardness value over a larger surface area, ensuring a reliable representation of the material’s overall hardness.

Applicable to a Wide Range of Materials

Brinell Testing is effective for both ferrous and non-ferrous metals, including materials like aluminum, copper, and brass, broadening its application across various industries.

Consistency and Accuracy

Brinell Hardness Testing helps minimise the impact of surface irregularities and localized structural differences, offering consistent and accurate results for quality control and material selection.

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

Whether you’re assessing forgings, castings, or bulk metal, we’ll ensure the Brinell Hardness Testing process is executed with precision.

Combine Hardness Testing with our full range of Destructive Tests.

Beyond just Hardness Testing, we offer the flexibility to carry out additional Mechanical Tests such as Tensile Testing or Impact Testing for a comprehensive understanding of your material’s performance. We also provide Chemical Analysis and Metallography Examinations to evaluate the material’s composition, microstructure, and other key characteristics.

By combining these tests, we provide you with a full picture of your metal’s properties, helping you make informed decisions on material selection, quality control, and process optimisation.

Common uses for Brinell Hardness Testing

Brinell Hardness Testing is widely used in industries like manufacturing, metallurgy, and quality control to evaluate the hardness of metallic materials, particularly for larger samples, forgings, castings, and bulk metals.

Forgings and castings

Ideal for testing larger, coarse samples produced through forging and casting processes.

Bulk metal Hardness

Used to determine the overall hardness of bulk metals for quality control and material selection.

Non-ferrous metals

Effective for evaluating materials like aluminium, copper, and brass.

Pre-heat treated steel

Commonly used to assess the hardness of pre-heat treated steel in manufacturing.

Comparative Hardness Testing

Preferred for consistency in hardness readings, minimising the impact of structural differences.

Our process

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What Brinell Hardness standards do you work to?

Brinell Hardness Testing standards and specifications we work with:

- 5mm ball diameter and 750kg load

- 10mm ball diameter and 3000kg load

- BS EN ISO 6506-1:2014

- ASTM E10:18

What is the difference between Brinell Hardness Testing and other Hardness Tests?

Brinell Testing uses a larger indenter and applies a higher load compared to other methods like Vickers or Rockwell.

This makes it ideal for testing larger, rougher materials where other tests may not be as effective or accurate.

What materials can be tested using Brinell Hardness Testing?

Brinell Hardness Testing is suitable for a wide range of materials, including both ferrous and non-ferrous metals such as steel, aluminium, copper, and brass.

It is particularly effective for testing larger or coarser samples like forgings, castings, and bulk metals.

Why is Brinell Hardness Testing preferred for large samples?

Brinell Testing is ideal for large or coarse materials because it uses a larger indenter and can accommodate a wider range of material surfaces.

This makes it suitable for testing heavy, bulk metal components like forgings and castings.

Let's talk about Brinell Hardness Testing

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team