Finish Testing

Humidity Testing

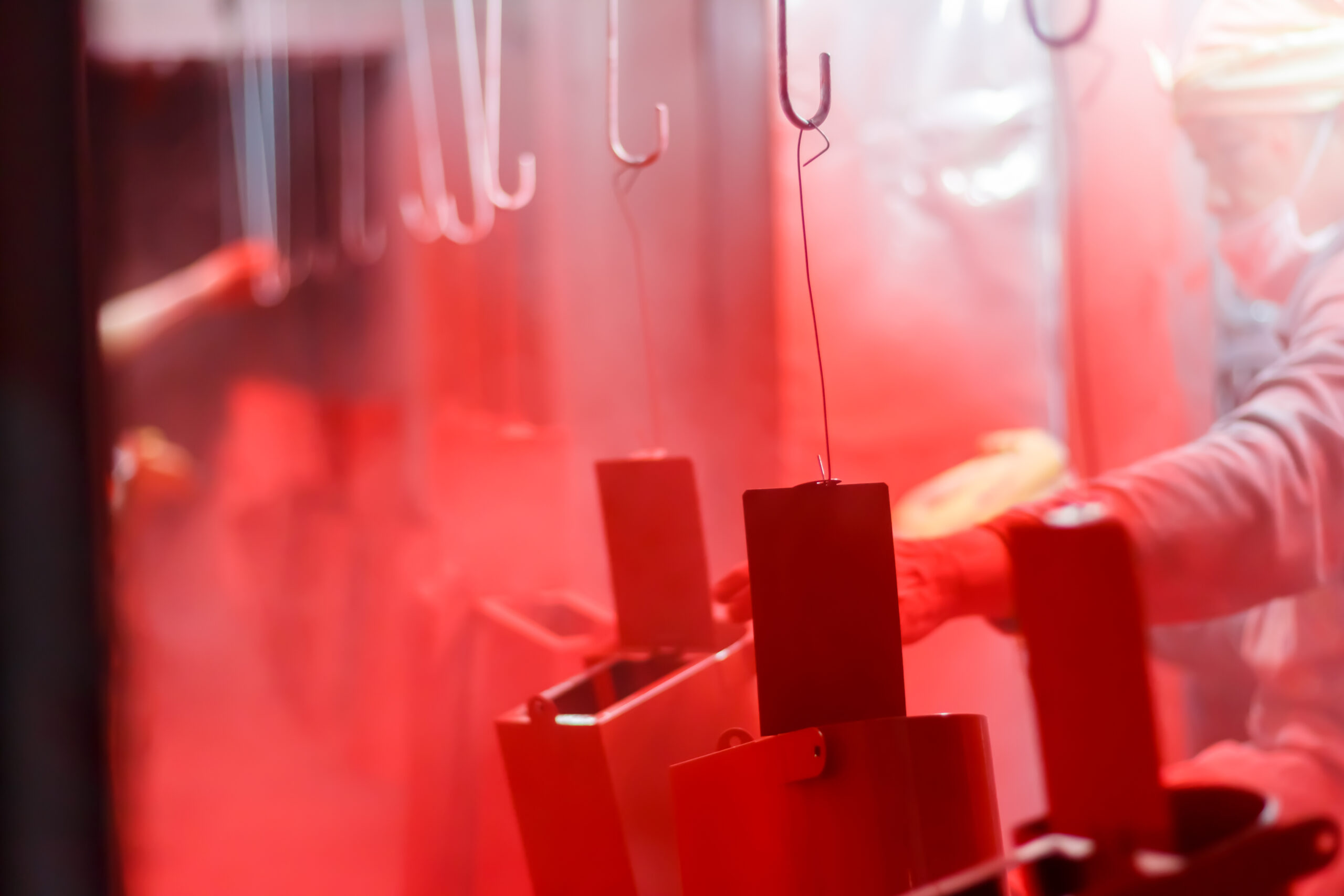

Our Humidity Tests help clients understand the limits of their metals. This includes steel, aluminium or other metal samples that have undergone a finishing process or coating system.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Humidity Testing?

Humidity Resistance Testing, also known as Humidity Testing or Humidity Exposure Testing, is a method used to assess how a material or product responds to elevated humidity levels. Humidity Resistance Testing is conducted to assess the impact of specific environmental conditions on a sample or material.

This test simulates real-life service conditions, including exposure to corrosive environments or prolonged heat and humidity. It is an important finish test that provides our customers with valuable insights into how their products will perform in humid conditions. Our dedicated humidity cabinet performs extended temperature and humidity testing cycles, as well as condensing water, in accordance with various international test standards and custom specifications. This ensures that we provide reliable data on the material’s performance and potential degradation. BES Group provide Humidity Tests on a variety of metals including aluminium alloys, stainless steel or coated metal samples.

Who we've partnered with

Let's talk about Humidity Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Humidity Tests from BES Group

When it comes to choosing humidity testing, it’s important to remember a few important factors. These factors ensure that the testing is done properly and gives valuable information about how your materials or products perform and last in humid conditions.

Humidity Levels

The test involves subjecting the specimen to elevated humidity levels, often exceeding normal environmental conditions. High humidity levels are created within the chamber to accelerate potential degradation processes.

Duration of Exposure

The duration of exposure varies depending on the testing standards and the intended application of the material or product. Exposure times can range from a few hours to several weeks.

Standards

Humidity resistance testing may be conducted according to specific industry standards or testing protocols. These standards provide guidelines on testing conditions, procedures, and acceptance criteria.

Applications

Humidity resistance testing is applicable to a wide range of industries, including electronics, automotive, aerospace, coatings, packaging, and materials science. It helps manufacturers ensure that products can withstand humid conditions without compromising performance.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

Accredited Service

Our engineers are highly qualified and experienced, and our services are accredited by a number of regulating bodies. This means that you can be confident that you are receiving the best possible service.

Trusted reliability

BES Group is a trusted and reliable provider of NDT services. We're proud to have a proven track record of providing high-quality services that meet the needs of our customers.

Decades of experience

Our team of expert inspectors have decades of experience in testing, and they have the expertise to identify and interpret the flaws in your materials.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Automotive

Explore sector

Consumer Products

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Power and Utilities

Explore sector

Rail

Explore sector

Renewables

Explore sector

Retail

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team