Destructive Testing

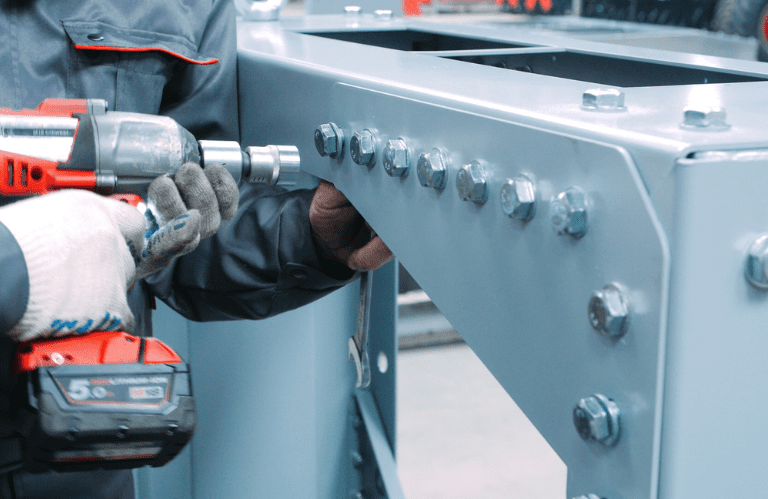

Fastener Testing

Fastener Testing is an intuitive testing method to determine mechanical and material fastener properties. We help clients to precisely evaluate fastener dependability and longevity.

Explore our process

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with

What is Fastener Testing?

Fastener Testing involves assessing and evaluating the mechanical and material properties of fasteners, which are devices used to join or affix two or more components together. Fasteners can include bolts, screws, nuts, rivets, and other types of connectors. The goal of Fastener Testing is to ensure that these components meet specific quality and performance standards, particularly in industries where safety and reliability are critical, such as automotive, aerospace, construction, and manufacturing.

Bolt Testing Services

Assess the strength and durability of your Bolt fasteners. We offer bespoke services to help you identify potential failures.

Nut Testing Services

We provide impartial, reliable insights to help ensure your Nuts meet the necessary standards for safety, quality and compliance.

Prevailing Torque Analysis

Evaluate your fastener’s resistance to rotation with our intuitive Testing Services.

Let's talk about Fastener Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Fastener samples we work with

Speak to us about the processSupporting your fastener testing needs through every stage of development

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Explore sector

Building, Properties and Real Estate

Explore sector

Rail

Explore sector

Power and Utilities

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Marine and Offshore

Explore sector

Manufacturing

Explore sector

Insurance

Explore sector

Highways

Explore sector

Healthcare

Explore sector

Consumer Products

What Our Fastener Testing Involves

Explore all sub-services- What standards do we test to?

- Mechanical Testing

- Metallurgy

- Chemical Analysis

- Salt Spray & Finish Testing

We work to several key standards and specifications for fasteners, including ASTM A193, ASTM A962, ASTM A194, BS EN ISO 3506-1, BS EN ISO 3506-2, BS EN SO 898-1, BS EN SO 898-2, ASTM F606/M, ASTM F738, ASTM A370 and BS EN ISO 898-6

As well as testing to National and International Standards, we test to well-known company standards including Aker, VGS, Wellstream, Statoil, FMC, Clyde Union, One Subsea, DEF Stan, NES and others.

Our capabilities cover a wide range of materials including carbon, low alloy, boron, and stainless steels, as well as duplex/super duplex, alloy 625, 718, 825, nickel aluminium bronzes, Monels, Inconels, Waspalloy, and titanium alloys. Rest assured, we have the necessary equipment and knowledge to deliver exceptional results

- Proof load of bolts and nuts

- Wedge tests for head soundness

- Tensile tests on full-size or machined samples

- Proof/ yield stress, total elongation

- Reduction in area and standard or microhardness testing (surface and core)

- 24-hour hardness testing including heat treatment* on nuts to ASTM A194

- Torque testing*

- Elevated temperature tensile testing on machined fastener feed stock or machined fasteners to ASTM E21 and BS EN SO 6892-2.

*Not UKAS accredited

- Decarburisation/carburisation testing

- Microstructural assessment including phase analysis, banding, segregation

- Microhardness to determine phase hardness e.g. martensite, ferrite, bainite etc.

- Longitudinal sectioning and macro etching to delineate forging flow lines at the bolt head-shank interface and reveal structural integrity along the bolt length from head to shank end.

- Fastener surface testing for the presence of hexavalent chromium (Cr6/CrVI) on suspect or designed chromate-treated surfaces.

- Failure investigations, including SEM/EDX analysis and fracture analysis to assess fastener failures

Chemical analysis of fasteners and/or starting material is clearly of fundamental importance – if the start material or semi-finished fastener bears the right chemistry, there is every chance that optimum subsequent downstream processing will result in specification compliance.

Any inorganic coating (e.g. plating, galvanising, sherardising) or organic coating (e.g. painting, plastic coating, Xylan, Dacromet coating) can be salt spray tested to ASTM B117/BS EN SO 9277. We can also offer plating/coating thickness measuring to BS EN SO 1463 and coating mass determination to BS EN 10346 and 10152.

If you need to understand how your fasteners will react to certain environments, we offer the following tests:

- Salt spray testing

- Humidity testing

- Plating/ coating thickness

- Coating mass testing

- Presence of hexavalent chromium (Cr6/CrVI)

-

What standards do we test to?

We work to several key standards and specifications for fasteners, including ASTM A193, ASTM A962, ASTM A194, BS EN ISO 3506-1, BS EN ISO 3506-2, BS EN SO 898-1, BS EN SO 898-2, ASTM F606/M, ASTM F738, ASTM A370 and BS EN ISO 898-6

As well as testing to National and International Standards, we test to well-known company standards including Aker, VGS, Wellstream, Statoil, FMC, Clyde Union, One Subsea, DEF Stan, NES and others.

Our capabilities cover a wide range of materials including carbon, low alloy, boron, and stainless steels, as well as duplex/super duplex, alloy 625, 718, 825, nickel aluminium bronzes, Monels, Inconels, Waspalloy, and titanium alloys. Rest assured, we have the necessary equipment and knowledge to deliver exceptional results

-

Mechanical Testing

- Proof load of bolts and nuts

- Wedge tests for head soundness

- Tensile tests on full-size or machined samples

- Proof/ yield stress, total elongation

- Reduction in area and standard or microhardness testing (surface and core)

- 24-hour hardness testing including heat treatment* on nuts to ASTM A194

- Torque testing*

- Elevated temperature tensile testing on machined fastener feed stock or machined fasteners to ASTM E21 and BS EN SO 6892-2.

*Not UKAS accredited

-

Metallurgy

- Decarburisation/carburisation testing

- Microstructural assessment including phase analysis, banding, segregation

- Microhardness to determine phase hardness e.g. martensite, ferrite, bainite etc.

- Longitudinal sectioning and macro etching to delineate forging flow lines at the bolt head-shank interface and reveal structural integrity along the bolt length from head to shank end.

- Fastener surface testing for the presence of hexavalent chromium (Cr6/CrVI) on suspect or designed chromate-treated surfaces.

- Failure investigations, including SEM/EDX analysis and fracture analysis to assess fastener failures

-

Chemical Analysis

Chemical analysis of fasteners and/or starting material is clearly of fundamental importance – if the start material or semi-finished fastener bears the right chemistry, there is every chance that optimum subsequent downstream processing will result in specification compliance.

-

Salt Spray & Finish Testing

Any inorganic coating (e.g. plating, galvanising, sherardising) or organic coating (e.g. painting, plastic coating, Xylan, Dacromet coating) can be salt spray tested to ASTM B117/BS EN SO 9277. We can also offer plating/coating thickness measuring to BS EN SO 1463 and coating mass determination to BS EN 10346 and 10152.

If you need to understand how your fasteners will react to certain environments, we offer the following tests:

- Salt spray testing

- Humidity testing

- Plating/ coating thickness

- Coating mass testing

- Presence of hexavalent chromium (Cr6/CrVI)

Frequently asked questions

What is a fastener?

Fasteners play a crucial role in every structure as they provide the necessary strength and durability to hold various materials together. Nuts, bolts, screws, and studs are commonly used as fasteners.

What happens if a fastener fails?

It is crucial to ensure that fasteners are comprised of the correct materials, suitable for their intended use. If a fastener fails to perform successfully whilst in use, it can lead to detrimental consequences for structures, and the health and safety of people around them. Fasteners make up a large majority of overall structural integrity and can cause the whole structure to fail if they do not operate correctly. Failed fasteners have previously been the cause behind plane crashes, industrial accidents, and ship disasters, such as oil spills and sinking accidents. This can cause negative legal implications for the companies involved in the fastener’s supply chain, so testing is crucial to prevent these issues from occurring.

How can fasteners be tested?

Fasteners can be tested in a variety of different ways. At Rotech laboratories, we are able to test and verify fasteners through services such as corrosion, mechanical testing, metallurgical testing, and chemical analysis, for alignment with a variety of UKAS specifications and standards.

What types of fasteners do you test?

We test all kinds of fasteners, from nuts, bolts, rivets, screws and more. One of our areas of expertise is testing full sized fasteners (unmachined fasteners), as well as tests on machined fasteners ready for market. We also offer testing on feedstock material in bar form, which is used in to manufacture fasteners, whether by cold heading, heat treatment, forging, thread rolling and many other processes.

What happens once a fastener has been tested?

Fastener test results are always provided to the customer, including fastener suppliers, manufacturers and external third parties involved in compliancy. It is extremely important for the customer to understand why the composition of a fastener may need alterations, or why as a consequence it has failed. This allows the supply chain to alter processes, to prevent failures from occurring, saving money, time, and the health and safety of end-users.

Why should fastener testing be outsourced?

Outsourcing fastener samples and materials to an independent testing laboratory such as ourselves, is a crucial step in ensuring products and materials are safe for use. If a fastener manufacturer or supplier does not have the capacity and expertise for testing, it is a cost-effective, and safe way for ensuring relevant compliancy.

Why do fasteners need be tested?

It is crucial to conduct independent testing on a fastener to determine if the product and its materials are suitable for their intended purpose. This allows manufacturers, suppliers, and testing laboratories to assess whether the product has been manufactured correctly, with the appropriate materials and treatments to withstand the required conditions. Our laboratory specialises in testing the maximum strain that a fastener can endure before breaking or bending. We also perform macro and micro examinations to closely examine the composition of materials. In the event that a fastener fails during use, a sample can be sent to our laboratory for testing to prevent future failures.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team