Electrical Solutions

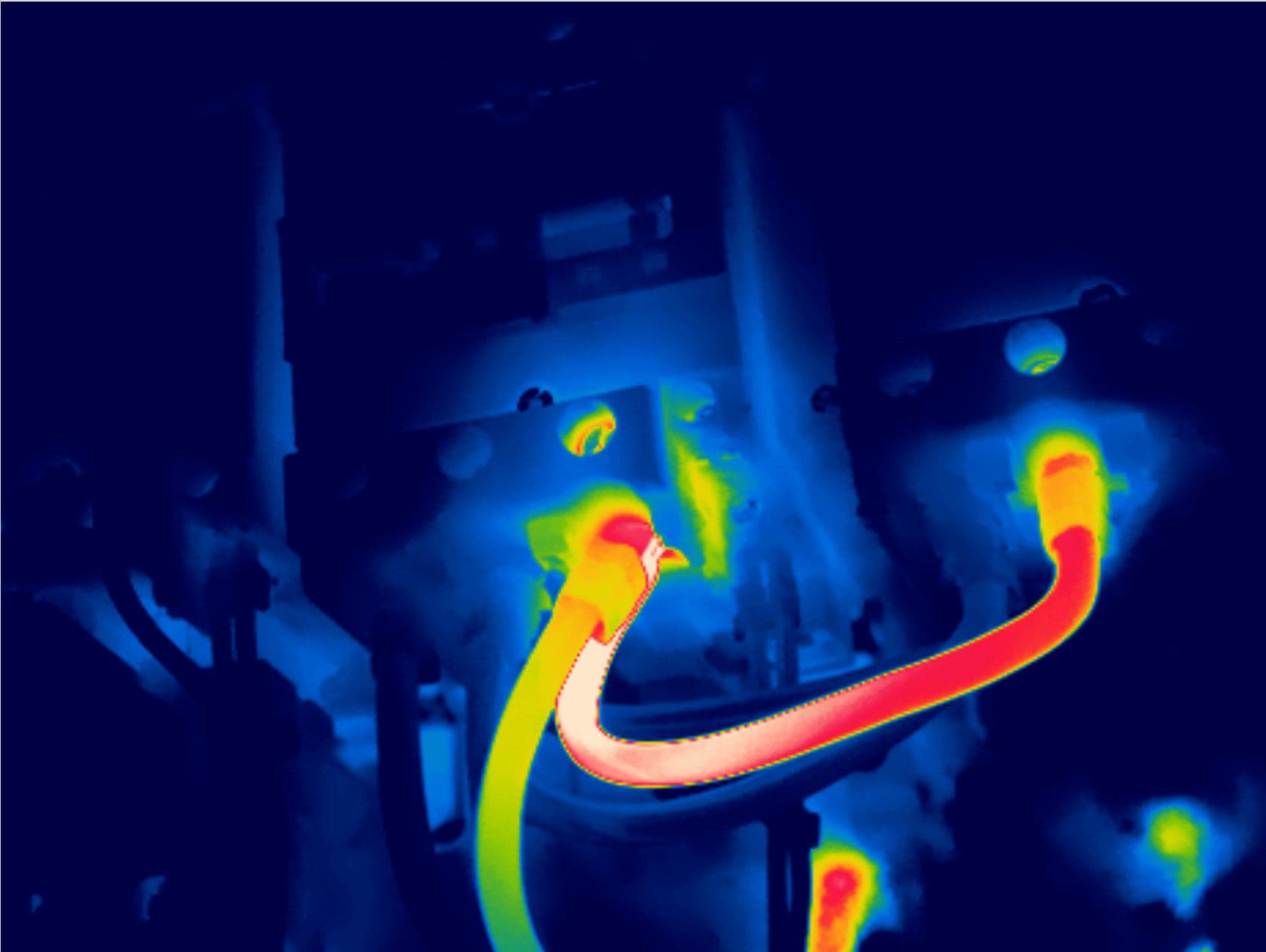

Thermal Imaging Surveys

Thermal Imaging Surveys act as your infrared vision, revealing electrical issues before they erupt into costly problems and cause downtime for your operations.

Explore our process

Interested? Let’s talk.

Send us an enquiry

Who we’ve partnered with...

What is a Thermal Imaging Survey?

The Electricity at Work Regulations Act 1989, Health & Safety at Work Act 1974 and BS 7671 (IEE Wiring Regulations 18th Edition as amended) suggest that electrical infrastructure be regularly maintained and tested to ensure compliance with safety guidelines, and that’s where we come in.

We’ll work with you and your site requirements when carrying out our thermal imaging surveys to provide you with a comprehensive diagnosis and solution of underlying issues within your plant and equipment. During a thermal imaging survey of your electrical equipment, our team at BES Group follows a precise process to uncover hidden issues and ensure the safety and efficiency of your systems. Our Electrical Engineers also accommodate for peak operational hours meaning you needn’t worry about shutdowns.

Our Thermal Imaging Surveys help to identify hidden threats such as: Faulty connections, overload circuits and other potential hazards hidden in plain sight.

Let's talk Thermal Imaging Surveys

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Our Thermal Imaging process

Speak to us about the processDuring a thermal imaging survey of your electrical equipment, our team at BES Group follows a precise process to uncover hidden issues and ensure the safety and efficiency of your systems.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Consumer Products

Explore sector

Finance

Explore sector

Healthcare

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Power and Utilities

Explore sector

Rail

Explore sector

Renewables

Explore sector

Retail

Explore sector

Transport, Logistics and Distribution Centres

Thermal Imaging Surveys at BES Group

Explore Thermal Imaging Surveys- Key benefits of Thermal Imaging Surveys

Early detection of potential hazards

Thermal imaging can be used to detect potential hazards, such as electrical fires, gas leaks, and structural defects, helping to prevent accidents and save lives.

Improved energy efficiency

Thermal imaging can be used to identify areas of heat loss, leading to energy savings and a reduction in costs!

Increased productivity

Thermal imaging can be used to identify and fix inefficiencies in industrial processes, boosting productivity and reducing costs.

-

Key benefits of Thermal Imaging Surveys

Early detection of potential hazards

Thermal imaging can be used to detect potential hazards, such as electrical fires, gas leaks, and structural defects, helping to prevent accidents and save lives.

Improved energy efficiency

Thermal imaging can be used to identify areas of heat loss, leading to energy savings and a reduction in costs!

Increased productivity

Thermal imaging can be used to identify and fix inefficiencies in industrial processes, boosting productivity and reducing costs.

Frequently asked questions

Why undertake a Thermal Imaging survey?

Thermal imaging is best carried out when the electrical system is functioning under normal conditions, which negates the need of operational downtime. Problems are spotted before they become larger issues, helping to increase the lifespan of your system or equipment.

Will this service disrupt the running of my business?

No. In fact, the more pressure on your electrical machinery the better. We are able to see how your system operates when operating at full load capacity, providing a more accurate reading.

What does the pre-survey planning process include

- Consultation and scope setting: We discuss your equipment, concerns, and desired outcomes to tailor the survey accordingly.

- Equipment selection: We choose the appropriate thermal imaging camera based on your specific needs and the type of equipment being inspected.

- Scheduling and site preparation: We coordinate the survey time to minimise disruption and advise on any needed preparations like removing obstructions or turning off lights.

What does the survey execution process include?

- Data collection: Our qualified engineers use the thermal imaging camera to scan electrical panels, boards, switches, connections, and other components.

- Temperature analysis: The camera converts infrared radiation into visual images, highlighting areas with abnormal heat signatures.

- Load correction factor: We utilise a unique formula that considers equipment load and ambient temperature, allowing for accurate assessment of permitted heat limits for each component.

- Real-time discussion and explanation: Our team discusses any anomalies observed with you, explaining their potential implications and next steps.

What does the analysis and reporting include?

- Image and data interpretation: Our technical team thoroughly analyses the thermal images and collected data, identifying potential hazards, areas of heat loss, and other key findings.

- Report generation: We create a comprehensive report detailing the survey results, including thermal images, measurements, identified anomalies, and recommendations for corrective actions.

- Discussion and action plan: We discuss the report findings with you in detail, ensuring a clear understanding of the issues and formulating a plan for addressing them.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team