Metallography

Cleanliness Testing Services

Cleanliness Testing is a critical aspect of quality control in various industries, ensuring that components, surfaces, and systems meet stringent cleanliness standards.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

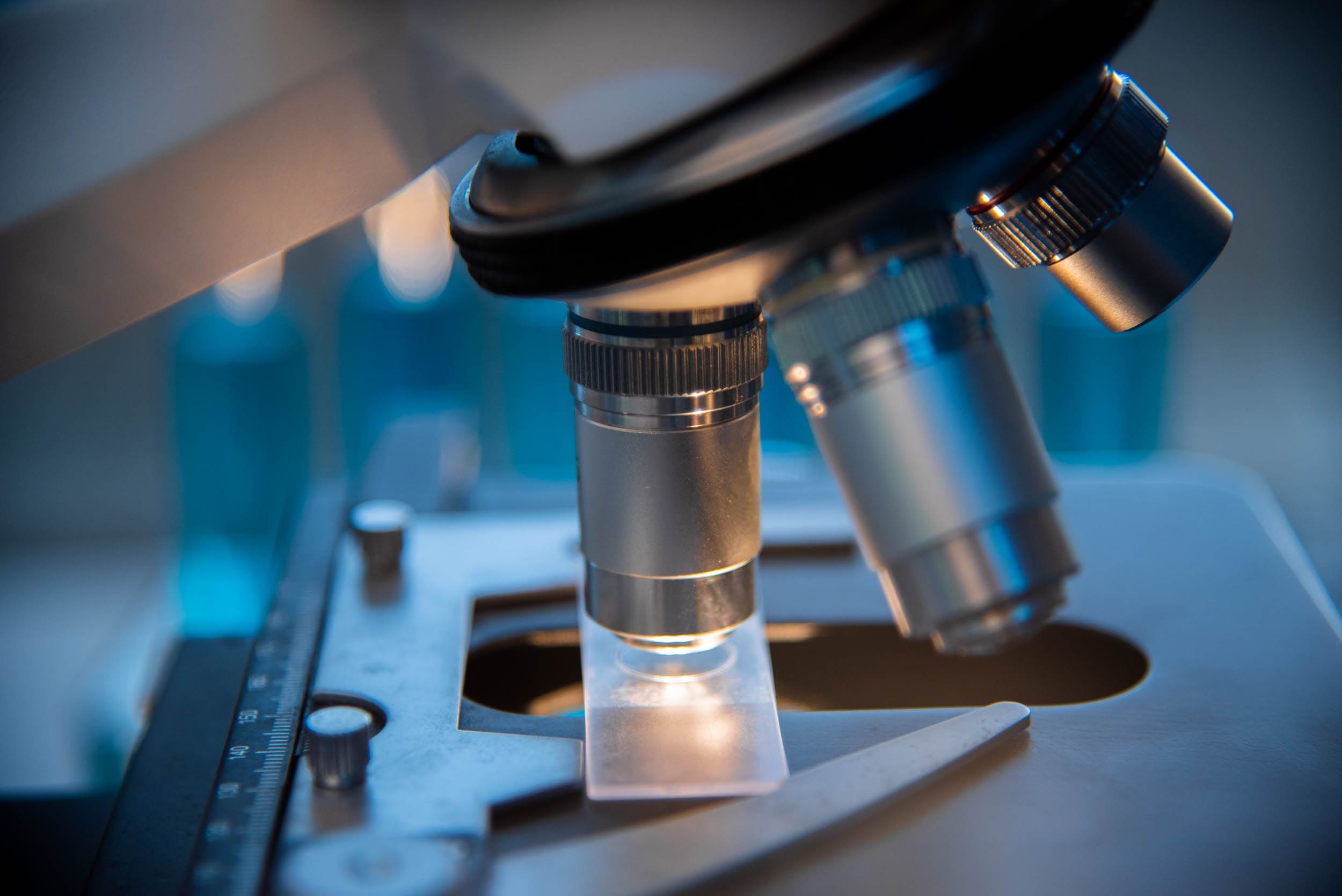

What is Cleanliness Testing?

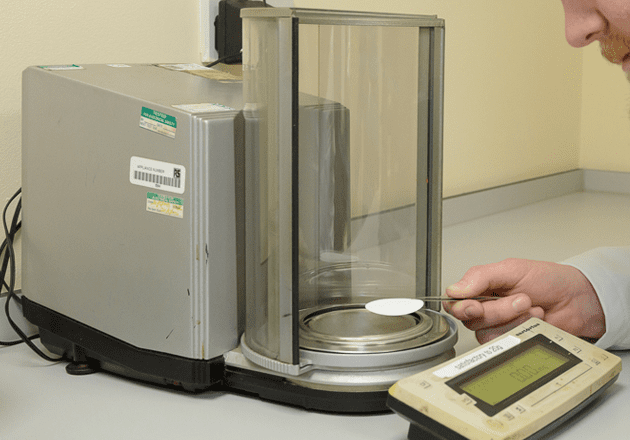

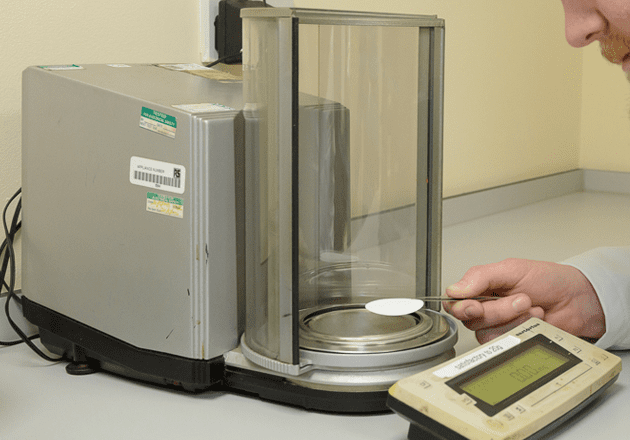

Our dedicated Nadcap accredited cleanliness testing laboratory means we can verify component cleanliness after manufacturing processes, where detection of levels of particulate contamination is seen as critical. Our tests cover specifications for suppliers such as Meggitt Control systems, where qualitative and quantitative detection of particulate contamination is crucial in ensuring parts are free from materials which may be harmful to the functionality of the end product.

Who we’ve partnered with...

Key benefits of Cleanliness Testing

Precision

The cleanliness laboratory is a contained, controlled environment in which we are able to carry out metal Cleanliness Testing and test components efficiently and effectively in accordance with Inspection Standards.

Compliant methods

Our Cleanliness Testing is conducted in strict compliance with Aerospace Quality System (AC7004) and Chemical Processing (AC7108) guidelines.

Let's talk about Cleanliness Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

In industries like automotive and aerospace, precision and meticulousness are absolutely crucial. Ensuring the cleanliness and removal of contaminants from components is vital to guarantee their reliability.

Our comprehensive cleanliness testing services are designed to guarantee the highest level of quality, reliability, and compliance with industry regulations.

In the automotive and aerospace sectors, and many others, precision and attention to detail are paramount. Contamination removal and cleanliness verification of components are really important in ensuring the reliability of components. This helps reduce the likelihood of costly field failures and caters for the demand for longer warranty periods.

We offer a cleanliness testing service from our designated Nadcap accredited facility, offering a fully contained cleanliness verification process and minimising risk of contamination.

We're Nadcap accredited for Cleanliness Testing

Nadcap accreditation for cleanliness testing is essential for ensuring the quality, reliability, and performance of materials and components used in aerospace and defense applications.

NADCAP accredited Cleanliness Testing laboratory.

Allows us to perform testing in compliance with Aerospace Quality System (AC7004) and Chemical Processing (AC7108). It helps uphold industry standards, meet customer expectations, mitigate risks, and demonstrate a commitment to excellence in cleanliness testing processes.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team