Fastener Testing

Prevailing Torque

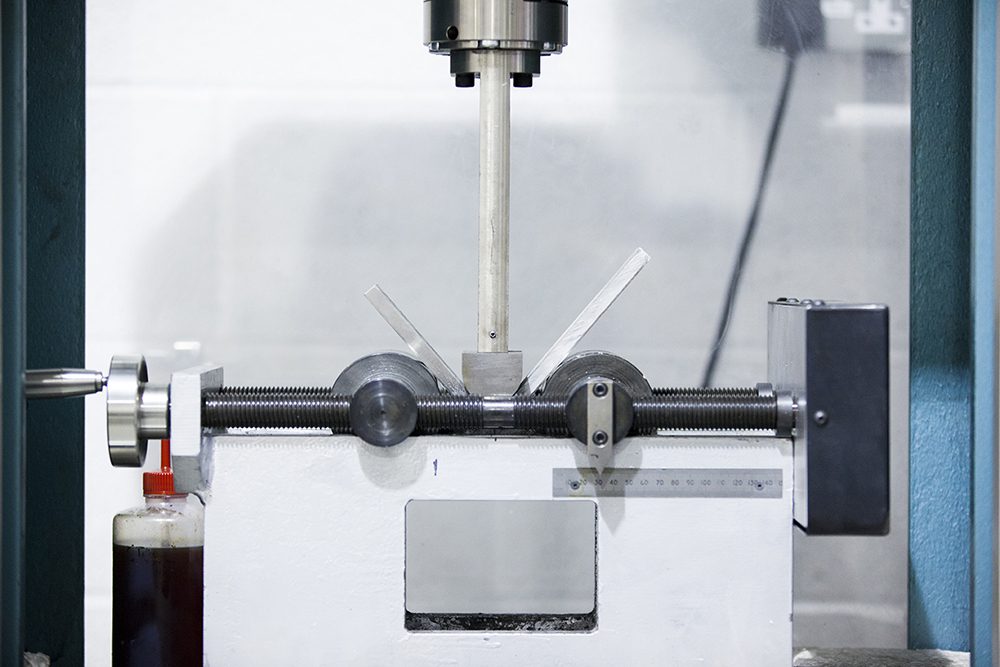

Prevailing Torque Testing is a Mechanical Testing method used to evaluate the resistance to rotation, also known as Prevailing Torque, of Fasteners that have special features to offer improved vibration resistance.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Prevailing Torque Testing?

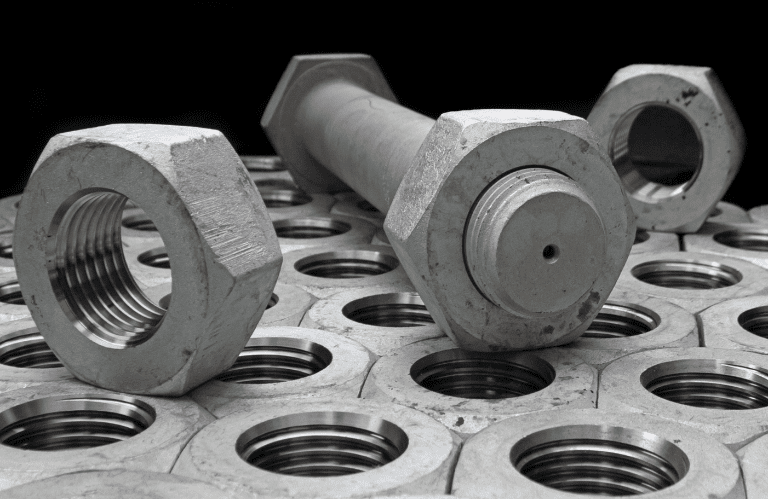

The main objective is to assess how well Fasteners can prevent themselves from loosening when exposed to external forces or vibrations. This evaluation is especially important for threaded fasteners like nuts and bolts, which are commonly used in crucial applications where maintaining the integrity of the joint is absolutely vital.

We offer Prevailing Torque testing on Fasteners up to sizes M20 to the following standards: – ISO 2320 Prevailing torque type steel nuts* – BS 4929-1 & 2 Steel hexagon prevailing torque type nuts* We can combine prevailing torque testing with Proof Load Testing on Nuts, Bolts, and Fasteners to provide a comprehensive overview of a sample’s behaviour, and accurate data analysis. The activities identified with * are not UKAS accredited.

Prevailing Torque is conducted to gain insights into the mechanical and physical characteristics of steel nuts and bolts, as well as locking nuts and threads. This is achieved by measuring the torque needed to overcome friction when they are being tightened in a specific setting.

Who we've partnered with

Key Benefits

Safety-critical insights for complex engineering industries

Fastener safety is crucial in instances where failures could have devastating consequences as well as risks to health, safety, and the environment.

Meet specified standards

Prevailing Torque Testing means that samples can be verified for use against the required minimum standards for specified applications.

Provides quality assurance

There is an increasing demand in the energy and power sector to provide quality assurance and safe testing and verification of fasteners through prevailing torque testing.

Reduce risk of failures and defects

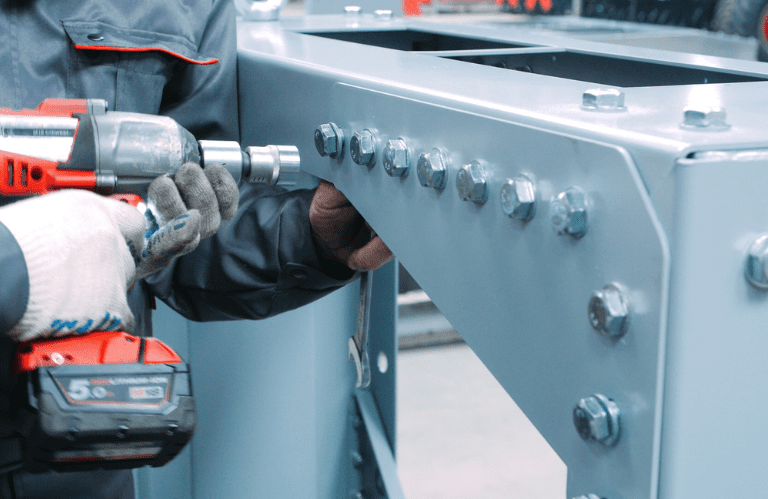

Testing will also aid with the manufacturing stage of the nuts, as they can be checked and verified at the time of assembly, reducing the risk of failures, defects, or flaws.

Let's talk about Prevailing Torque

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Prevailing Torque Testing from the BES Group

Which industries benefit most from Prevailing Torque Testing?

These types of fasteners are found in most industries and sectors, from construction, oil and gas to commercial applications and household items such as furniture and bikes. Locking nuts and threads are extremely common types of fasteners. From tightening a bolt on a flat-pack piece of furniture during assembly, to manufacturing a rotating blade for a wind turbine, we see these fasteners in every industry, including construction, oil and gas, commercial and household applications.

Ensuring fastener safety with Prevailing Torque

It is safety-critical that prevailing torque nuts are tested accurately for a range of complex engineering industries, including nuclear, power and energy sectors, aerospace, and marine applications. Fastener failures across submarines, nuclear reactors or aeroplanes can have devastating consequences as well as risks to health, safety and the environment. Prevailing torque testing is an important aspect of fastener design and quality control, especially in applications where the consequences of joint failure due to self-loosening could be severe. It helps manufacturers ensure that fasteners perform reliably in demanding environments.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team