Fastener Testing

Bolt Testing

At BES Group, we can help you assess the strength and durability of your fasteners. We test a range of bolts for mechanical, metallurgical and chemical properties from sizes M2 up to M27.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Bolt Testing?

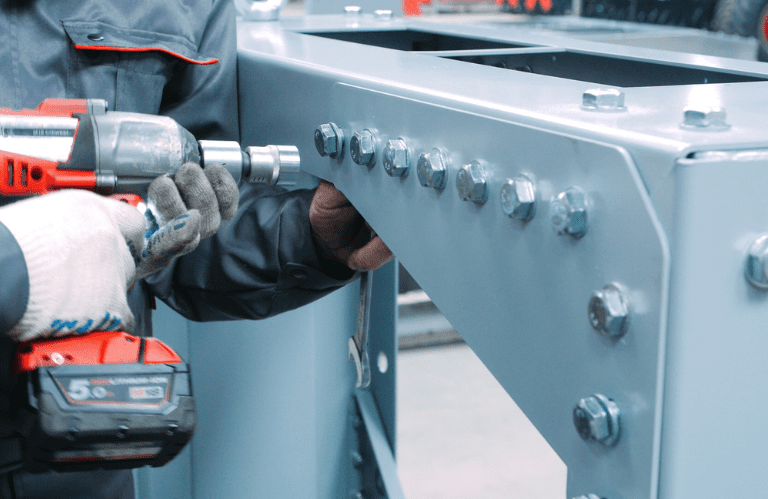

Bolts and nuts are widely used fasteners due to their ease of assembly and disassembly. Bolt Testing plays a vital role in ensuring the safety and reliability of machines and equipment.

This process guarantees that bolts can endure their designated load and function effectively under various stresses and conditions. By identifying potential failures, it also helps in minimising costs by reducing instances of failures, downtime, and maintenance. Fasteners and raw materials for producing fasteners must be routinely tested to ensure that they are suitable to be used in their intended environment. Choosing a UKAS accredited testing laboratory for your bolt testing means that our processes and testing procedures are of the highest quality, giving you confidence in your products, and reassurance that they are fit to be used in real-service conditions.

Who we've partnered with

Let's talk about Bolt Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

We can analyse a range of bolts made from different metals.

Most commonly, bolts are made from steel alloys, such as stainless steel, low carbon steel, and chromium as this offers the best protection against corrosion and corrosive environments. Titanium, Cupro Nickel and Aluminium, Inconel are also used to manufacture bolts depending on their end use.

Bolts must be produced from the right material.

If an inappropriate metal or material is used, the bolt may experience fatigue, corrosion, or failure during service. We offer independent Bolt Testing Services using:

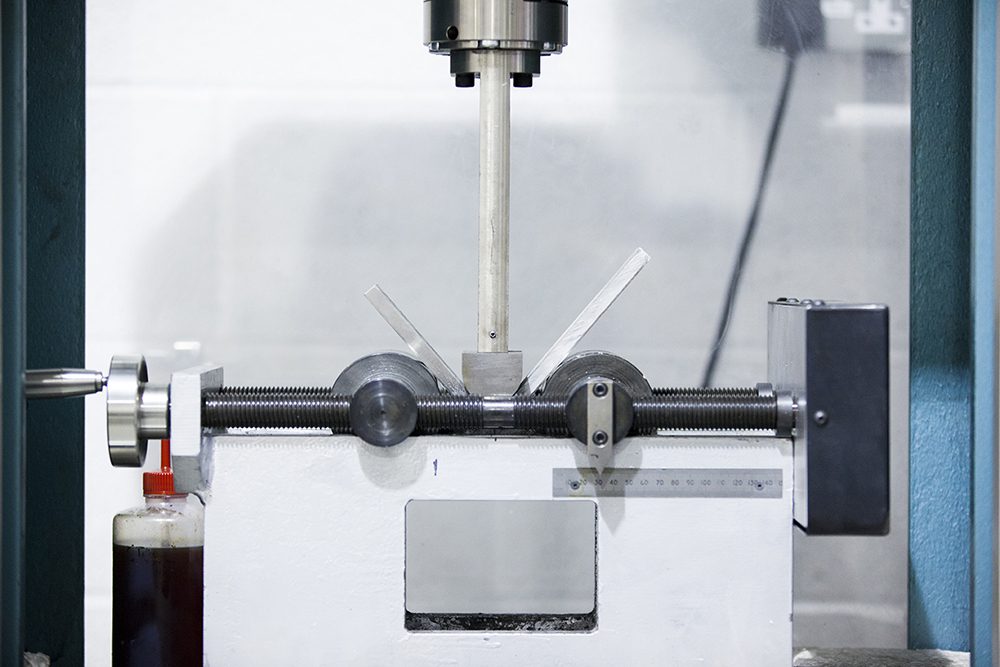

What our Bolt Testing Services include

| Test | Description |

|---|---|

| Mechanical Testing |

|

| Metallurgical Testing |

|

| Chemical Analysis |

|

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

Frequently asked questions

Can bolts undergo any further treatments?

To further enhance the performance of steel, bolts may undergo additional treatments such as plating, coating, or galvanization.

What materials are Bolts made from?

Bolts are commonly made from stainless 18-8 steel, containing 18% chromium and 8% nickel. Another type of steel that is more resistant to corrosion is stainless 316, and is often used in salt water and chlorine environments. Bolts may also be made from stainless 410 material, which is a more durable steel but less resistant to corrosion.

Alloy steel is a high-strength material that can be heat treated to produce durable bolts.

What type of bolts do BES Group test?

We test a range of bolts, including:

- Anchor bolts

- Blind bolts

- Carriage bolts

- Double end bolts (also called Tap End Studs)

- Eye Bolts

- Flange bolts

- Hex bolts

- Machine bolts and machine screws

- Socket head bolts, Square head bolts

- T-head bolts

- U-bolts

And many more!

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Power and Utilities

Explore sector

Rail

Explore sector

Renewables

Explore sector

Aerospace and Defence

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team