Chemical Analysis

ICP-OES Analysis

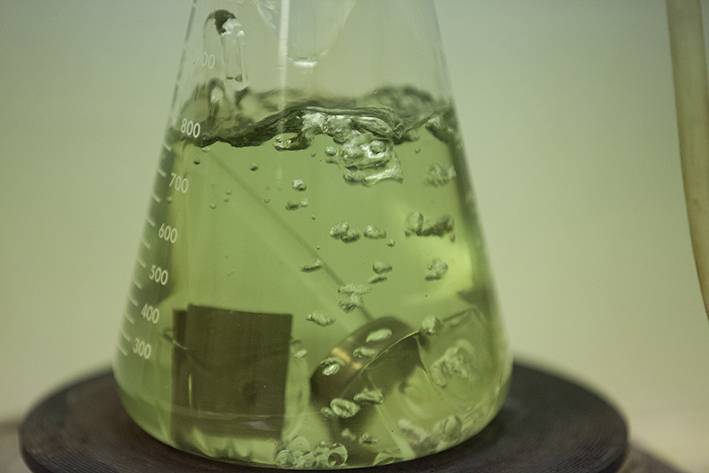

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is a technique used to determine the levels of certain elements or compositions within metals.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is ICP-OES Analysis?

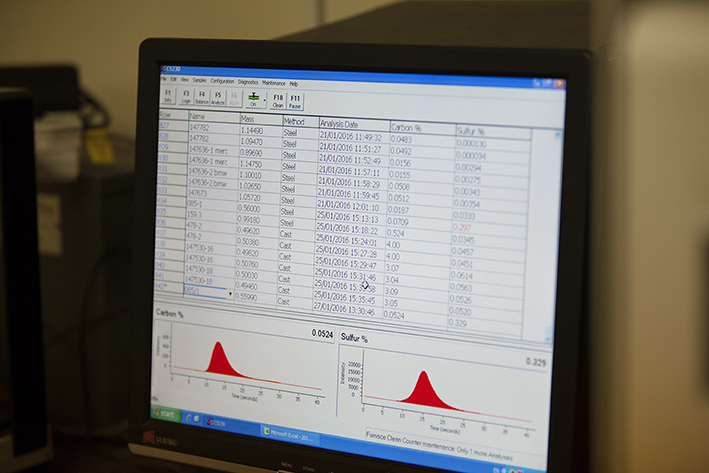

ICP OES analysis is a valuable tool we use to understand the chemical properties of different materials. By using a plasma torch, we can ionize and excite the material, allowing us to identify elements based on their unique characteristics. At BES Group, we can determine the quantity of these elements by analysing the intensity of emission lines during testing.

ICP-OES Analysis is particularly suitable for identifying major and trace elements within carbon steels, alluminium alloys and stainless steels. In some cases, this analysis may be more suitable for smaller samples that may not be compatible with Spark-OES. Rest assured, our goal is to assist our customers in establishing whether a material is suitable for its intended purpose, determining the type of material, and ensuring quality control, safety, and compliance measures are met.

Who we've partnered with

Key benefits

High sensitivity

ICP-OES Analysis is especially useful for detecting elements at very low concentrations.

High accuracy

Gain accurate, precise quantitative results to drive quality control, research and development.

Let's talk about ICP-OES Analysis

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

ICP-OES Analysis from the BES Group

Receive accurate and reliable test results with qualitative and quantitative data

The combination of sensitivity, speed, accuracy, and versatility makes ICP-OES a valuable analytical technique for a wide range of applications in research, industry, and environmental monitoring. ICP-OES is employed in metallurgical and mining industries for elemental analysis of ores, metals, alloys, and other materials. It helps characterize mineral compositions, assess metal purity, and optimize production processes.

High Sensitivity & Multiple Element Analysis

By detecting elements at very low concentrations ICP OES Analysis is especially useful for quality control, research and development. This high sensitivity is crucial for many application, such as trace metal analysis. ICP-OES can simultaneously analyse multiple elements in a single sample, which makes this advantageous when assessing complex samples containing many different elements, as it allows for comprehensive elemental profiling without the need for separate tests to be performed.

Accurate Data from Small Sample Requirements

ICP-OES provides accurate and precise quantitative results, making it suitable for both research and quality control application where reliable and accurate data is vital. Sample preparation for ICP-OES analysis is often relatively simple, involving dissolution of the sample in an appropriate solvent. This minimises the potential for sample contamination and reduces the time and effort required for analysis.

What can ICP-OES Analysis detect?

Utilising ICP-OES Analysis, BES Group can determine a variety of UKAS accredited element composition on:

| Metal | Element composition |

| Wrought aluminium alloys |

Bismuth (Bi), Chromium (Cr), Copper (Cu), Gallium (Ga), Iron (Fe), Lead (Pb), Magnesium (Mg), Manganese (Mn), Nickel (Ni), Silicon (Si), Tin (Sn), Titanium (Ti), Vanadium (V), Zinc (Zn), Zirconium (Zr) |

| Ferrous based alloys: | Aluminium (Al), Boron (B), Chromium (Cr), Copper (Cu), Manganese (Mn), Molybdenum (Mo), Nickel (Ni), Niobium (Nb), Phosphorus (P), Silicon (Si), Titanium (Ti), Vanadium (V) |

Our team can also determine other non-UKAS accredited elements not listed above according to customer requirements.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Guide to Young’s Modulus and Material Stiffness

Testing

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team