Destructive Testing

Chemical Analysis

BES Group are here to help you understand the composition and qualities of your metals. We detect any irregularities or impurities guaranteeing your products meet necessary standards and quality benchmarks.

Explore specialist sub-services

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with

Chemical Analysis of Metals

Chemical testing of metals is achieved using qualitative and quantitative data, giving you a complete understanding of what your products are made of. Achieving the desired mechanical, corrosion, and physical properties is crucial for manufacturers, and we can assist in ensuring that your products meet these requirements. We specialise in the Chemical Analysis of Metals including:

ICP-OES Analysis

ICP OES analysis helps clients to understand the chemical properties of different materials. We also help determine the quantity of elements found.

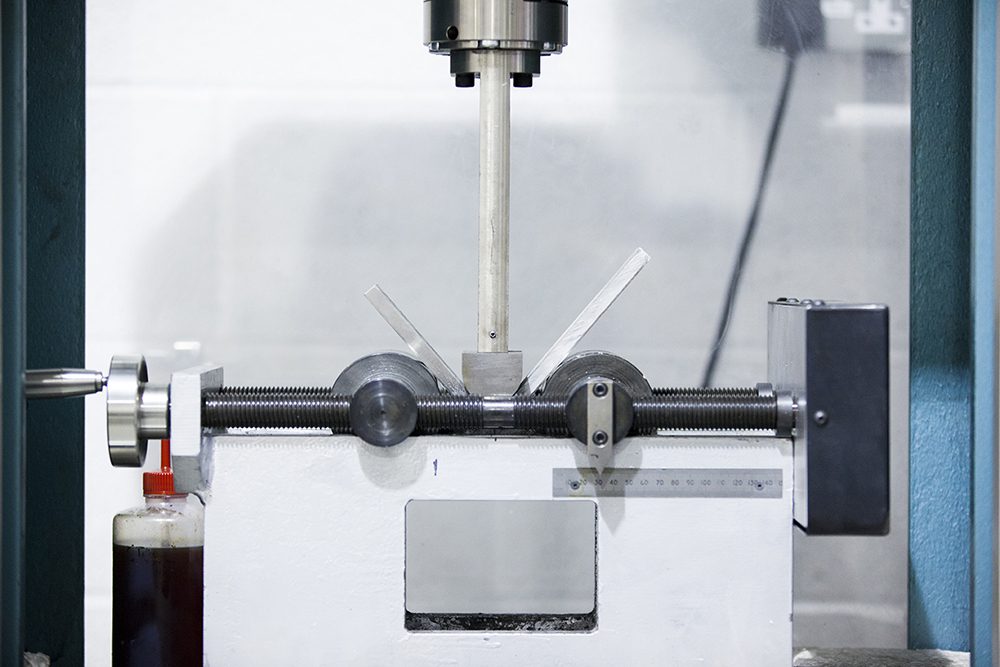

Spark-OES Analysis

Spark OES (Optical Emission Spectroscopy) is an analytical technique used for determining the elemental composition of materials.

Carbon, Nitrogen & Sulphur Analysis

We analyse the concentration levels and detect trace amounts of combustion gases within a metal sample, such as Carbon, Sulphur and Nitrogen.

Copper Nickel Alloys

We specialise in testing Copper Nickel Alloys to our inhouse procedures, as required by Naval Engineering Standards (NES) and UK Defence Standards (DEF Stans).

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

About Chemical Analysis Services

Explore all sub-services- ICP-OES Analysis

- Spark-OES Analysis

- Carbon, Sulphur & Nitrogen Analysis

- Copper Nickel Alloys

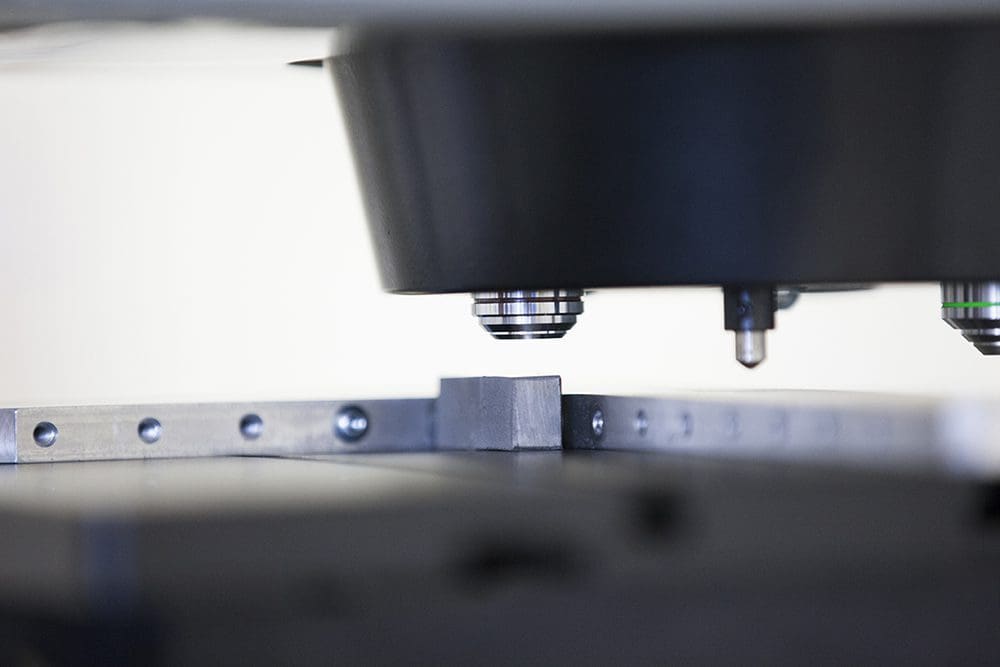

ICP-OES analysis, also known as Inductively Coupled Plasma Optical Emission Spectroscopy,

It is a powerful technique used in the field of analytical science. Through the ionization and excitation of the material using a plasma torch, ICP-OES identifies specific characteristics and compositions within materials, while the intensity of emission lines during testing helps determine the quantity of these elements.

This technique is particularly useful for examining various metals, including carbon steels, stainless steels, and aluminium alloys, to identify both major and trace elements present in the material. In cases where smaller samples are involved, ICP-OES may be a more appropriate choice compared to Spark-OES.

This analysis plays a crucial role in understanding the chemical properties of various materials, helping to assess your product’s suitability for specific purposes, and aids with quality, compliance and safety measures.

Using Optical Emission Spectroscopy (OES), we can conduct thorough examinations on a diverse array of metals and alloys.

Spark OES (Optical Emission Spectroscopy) is an analytical technique used for determining the elemental composition of materials. This method relies on the principles of atomic emission spectroscopy to identify and quantify the elements present in a sample.

Spark OES is widely used in industries where precise knowledge of the elemental composition of metals is crucial. This includes applications in metallurgy, quality control of metal alloys, and material testing. The technique is valued for its speed, precision, and ability to analyse a wide range of elements simultaneously.

Our chemistry team can analyse the concentration levels and detect trace amounts of combustion gases within a metal sample, such as Carbon, Sulphur and Nitrogen.

In the manufacturing process of metal products or samples, inconsistencies or irregularities can arise within the material. Using specialist laboratory equipment, we can identify these trace gases and assess whether their levels are within acceptable limits for the production or manufacturing process. By employing infrared absorption techniques, this method measures the heat transfer in the sample, enabling accurate measurement of the concentration of combustible gases. Learn more about carbon, nitrogen and sulphur analysis.

BES Group specialises in testing Copper Nickel Alloy to our inhouse procedures, as required by Naval Engineering Standards (NES) and UK Defence Standards (DEF Stans).

These alloys, known as Cupronickels, are composed of high levels of copper and nickel. Cupronickels possess exceptional resistance to corrosive environments, including saltwater and conditions rich in oxides. As a result, they are highly sought after in industries such as marine, oil, and gas. Due to their anti-corrosive properties, these alloys are commonly used in piping and marine applications.

The high nickel content in these alloys makes our chemical analysis and corrosion science tests particularly valuable to our customers, who come from various industries such as Defence and the Oil & Gas sector.

-

ICP-OES Analysis

ICP-OES analysis, also known as Inductively Coupled Plasma Optical Emission Spectroscopy,

It is a powerful technique used in the field of analytical science. Through the ionization and excitation of the material using a plasma torch, ICP-OES identifies specific characteristics and compositions within materials, while the intensity of emission lines during testing helps determine the quantity of these elements.

This technique is particularly useful for examining various metals, including carbon steels, stainless steels, and aluminium alloys, to identify both major and trace elements present in the material. In cases where smaller samples are involved, ICP-OES may be a more appropriate choice compared to Spark-OES.

This analysis plays a crucial role in understanding the chemical properties of various materials, helping to assess your product’s suitability for specific purposes, and aids with quality, compliance and safety measures.

-

Spark-OES Analysis

Using Optical Emission Spectroscopy (OES), we can conduct thorough examinations on a diverse array of metals and alloys.

Spark OES (Optical Emission Spectroscopy) is an analytical technique used for determining the elemental composition of materials. This method relies on the principles of atomic emission spectroscopy to identify and quantify the elements present in a sample.

Spark OES is widely used in industries where precise knowledge of the elemental composition of metals is crucial. This includes applications in metallurgy, quality control of metal alloys, and material testing. The technique is valued for its speed, precision, and ability to analyse a wide range of elements simultaneously.

-

Carbon, Sulphur & Nitrogen Analysis

Our chemistry team can analyse the concentration levels and detect trace amounts of combustion gases within a metal sample, such as Carbon, Sulphur and Nitrogen.

In the manufacturing process of metal products or samples, inconsistencies or irregularities can arise within the material. Using specialist laboratory equipment, we can identify these trace gases and assess whether their levels are within acceptable limits for the production or manufacturing process. By employing infrared absorption techniques, this method measures the heat transfer in the sample, enabling accurate measurement of the concentration of combustible gases. Learn more about carbon, nitrogen and sulphur analysis.

-

Copper Nickel Alloys

BES Group specialises in testing Copper Nickel Alloy to our inhouse procedures, as required by Naval Engineering Standards (NES) and UK Defence Standards (DEF Stans).

These alloys, known as Cupronickels, are composed of high levels of copper and nickel. Cupronickels possess exceptional resistance to corrosive environments, including saltwater and conditions rich in oxides. As a result, they are highly sought after in industries such as marine, oil, and gas. Due to their anti-corrosive properties, these alloys are commonly used in piping and marine applications.

The high nickel content in these alloys makes our chemical analysis and corrosion science tests particularly valuable to our customers, who come from various industries such as Defence and the Oil & Gas sector.

Frequently asked questions

What does the process include?

Qualitative Chemical Analysis helps in identifying compounds and elements present within your material, while quantitative methods measure the number of different substances present.

We will provide you with detailed information about the properties and characteristics of your metal sample, such as the amount of carbon in a sample of steel, or the nickel content of your material.

Achieving the desired mechanical, corrosion, and physical properties is crucial for manufacturers, and we can assist in ensuring that your products meet these requirements.

What materials do we Test for Chemical Analysis?

We test a wide range of metal samples including

- Plain Carbon, and Alloy Steels, Stainless, Duplex, 6 Mo Steels and Tool Steels

- Grey and Ductile Cast Irons

- Aluminium

- Zinc Alloys, Ferrous Based Alloys

- White Metals, Cast Iron

- Cobalt Alloys, Ferro Alloys, Nickel Alloys, Copper Alloys

- Carbon Steels and Refractories

- High alloyed steels and low alloyed steels

Which materials do BES Group test to determine Carbon and Sulphur?

To determine Carbon & Sulphur, we test the following materials:

- Nickel Alloys

- Ferrous based alloys

- Aluminium alloys

Which materials we test to determine Nitrogen?

To determine Nitrogen, we test the following materials:

- High and low alloyed steels

- Nickel and cobalt alloys

- Plain carbon steels

What do our Cupronickel alloys Testing Services include?

- Chemical Analysis using ICP-OES to verify the composition and material grade.

- Tensile testing and hardness testing to ensure the mechanical properties of the material.

- Metallurgical investigations to gain a deeper understanding of the material’s behaviour.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Chemical Analysis services from BES Group

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team