Lubrication Services

Lubrication Surveys

Ensure your equipment is consistently and efficiently lubricated. We help clients enhance equipment reliability and operational performance by conducting comprehensive lubrication surveys.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What are Lubrication Surveys?

Our team of industry experts conduct thorough assessments, identifying and resolving potential issues to optimise lubrication processes. We offer a diverse range of services to ensure your equipment is consistently and efficiently lubricated, reducing downtime and resulting in substantial cost savings.

We offer a tailored approach that goes beyond routine maintenance, addressing the unique needs of your machinery. Choosing BES Group means investing in comprehensive solutions that lead to improved reliability, enhanced performance, and long-term savings. Experience the difference where expertise meets excellence in lubrication solutions, ensuring your equipment operates at peak efficiency, saving you valuable time and money.

Who we've partnered with...

Key benefits of our Lubrication Surveys

Prevent unplanned downtime

A lubrication survey can help to identify potential problems with the lubrication program before they cause equipment failure. This can help to prevent unplanned downtime, which can be costly and disruptive.

Improve equipment reliability

A lubrication survey can help to identify and correct any problems with your lubrication programme. This can help to improve equipment reliability and reduce the rick of equipment failure.

Save money

A lubrication survey can help to identify areas where the lubrication program can be improved. This can help to save money on lubricants, labour, and maintenance costs.

Contact us

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How can our Lubrication Surveys help you?

Optimised lubrication is not just about putting oil in the right place. It’s about ensuring that the oil is the right type, the right quantity, and the right temperature at all times.

Why are Lubrication Surveys important?

It’s also about keeping the equipment clean and free of contaminants. Lubrication Surveys will help ensure you have optimised lubrication and the benefits that come from this. Poor lubrication is a major cause of equipment failure. In fact, studies have shown that up to 60% of all mechanical wear-related failures are caused by poor lubrication.

Lubrication services from BES Group

At BES Group, we have been working with our customers for decades to ensure they are optimising their lubricants. Our expert team of engineers and laboratory technicians have experience in a wide range of industries, and are highly qualified.

Our specialist service offering

Explore Lubrication Surveys- Basic Assessment Service

- Bronze Service

- Silver Service

- Gold Service

- Platinum Service

Lubrication Basic Assessment Service

To assess your lubrication management maturity, we’ll perform a plant walk to create a report detailing what you are doing well and what we may be able to help you do better, providing a simple look at where you are and where you could be.

We can pick up where you have left off.

If your manpower is stretched to its fullest, we can enable you to free up your maintenance personnel to carry out direct maintenance, whilst we get on with stabilising the existing lubrication plan. We act as an extension to your current workforce, and continually advise you of any issues so you can make management decisions depending upon the criticality to your business needs.

We can carry out a full lubrication survey on site.

Using Vibration Analysis and Ultrasound technologies, we can pick up where you have already started. However, we can also help you create a continuous improvement program where we can slowly start to make improvements.

We will recommend improvements based on condition, making sure that stores are effective and the best that they can be. We will implement improvements at a gradual pace to easily integrate into your daily operations.

We’re committed to getting the job done right the first time. As part of this, we will provide you with the right personnel to drive the optimisation to completion in an efficient and timely manner. And, we’ll run lubrication activities that are based upon the needs of the asset and your business objectives.

We can start from the beginning.

We will do a full and expert lubrication study incorporating complementary technologies, such as oil and Vibration Analysis and Ultrasound technologies. With this, we’ll create a continuous improvement program that we can implement and use.

Our process

- Full onsite lubrication study

- Determine asset list

- Evaluate the condition of each asset

- Evaluate the condition of the lubricant in use

- Use both 2 and 3 to determine the suitability of the lubricant for the asset

- Evaluate the state of filtration and cooling systems

- Thoroughly assess current lubricant stores and fluid transfer capability and status.

- Evaluate and optimise current lubrication procedures

- Evaluate and optimise current lubrication frequencies

- Evaluate stocks and spares

- Tailored report created on our online portal (Asset Insight 365)

This service includes everything in the gold service, along with a specialist wraparound management system that’s aligned to international standards.

This is to ensure it offers a fully operational lubrication management plan that meets the needs of standards, including PAS 55 – ISO 55000 – as well as the lubrication standards developed by the global lubrication industry – lubrication asset management standard ICML 55.1/55.2/55.3.

This provides a fully optimised management approach which delivers assurance. It is also an objective demonstration of compliance and ongoing optimisation, relating lubrication to maintenance, asset management and corporate governance.

Contact BES Group today to learn more about our Lubrication services

-

Basic Assessment Service

Lubrication Basic Assessment Service

To assess your lubrication management maturity, we’ll perform a plant walk to create a report detailing what you are doing well and what we may be able to help you do better, providing a simple look at where you are and where you could be.

-

Bronze Service

We can pick up where you have left off.

If your manpower is stretched to its fullest, we can enable you to free up your maintenance personnel to carry out direct maintenance, whilst we get on with stabilising the existing lubrication plan. We act as an extension to your current workforce, and continually advise you of any issues so you can make management decisions depending upon the criticality to your business needs.

-

Silver Service

We can carry out a full lubrication survey on site.

Using Vibration Analysis and Ultrasound technologies, we can pick up where you have already started. However, we can also help you create a continuous improvement program where we can slowly start to make improvements.

We will recommend improvements based on condition, making sure that stores are effective and the best that they can be. We will implement improvements at a gradual pace to easily integrate into your daily operations.

We’re committed to getting the job done right the first time. As part of this, we will provide you with the right personnel to drive the optimisation to completion in an efficient and timely manner. And, we’ll run lubrication activities that are based upon the needs of the asset and your business objectives.

-

Gold Service

We can start from the beginning.

We will do a full and expert lubrication study incorporating complementary technologies, such as oil and Vibration Analysis and Ultrasound technologies. With this, we’ll create a continuous improvement program that we can implement and use.

Our process

- Full onsite lubrication study

- Determine asset list

- Evaluate the condition of each asset

- Evaluate the condition of the lubricant in use

- Use both 2 and 3 to determine the suitability of the lubricant for the asset

- Evaluate the state of filtration and cooling systems

- Thoroughly assess current lubricant stores and fluid transfer capability and status.

- Evaluate and optimise current lubrication procedures

- Evaluate and optimise current lubrication frequencies

- Evaluate stocks and spares

- Tailored report created on our online portal (Asset Insight 365)

-

Platinum Service

This service includes everything in the gold service, along with a specialist wraparound management system that’s aligned to international standards.

This is to ensure it offers a fully operational lubrication management plan that meets the needs of standards, including PAS 55 – ISO 55000 – as well as the lubrication standards developed by the global lubrication industry – lubrication asset management standard ICML 55.1/55.2/55.3.

This provides a fully optimised management approach which delivers assurance. It is also an objective demonstration of compliance and ongoing optimisation, relating lubrication to maintenance, asset management and corporate governance.

Contact BES Group today to learn more about our Lubrication services

Our Lubrication Survey process

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

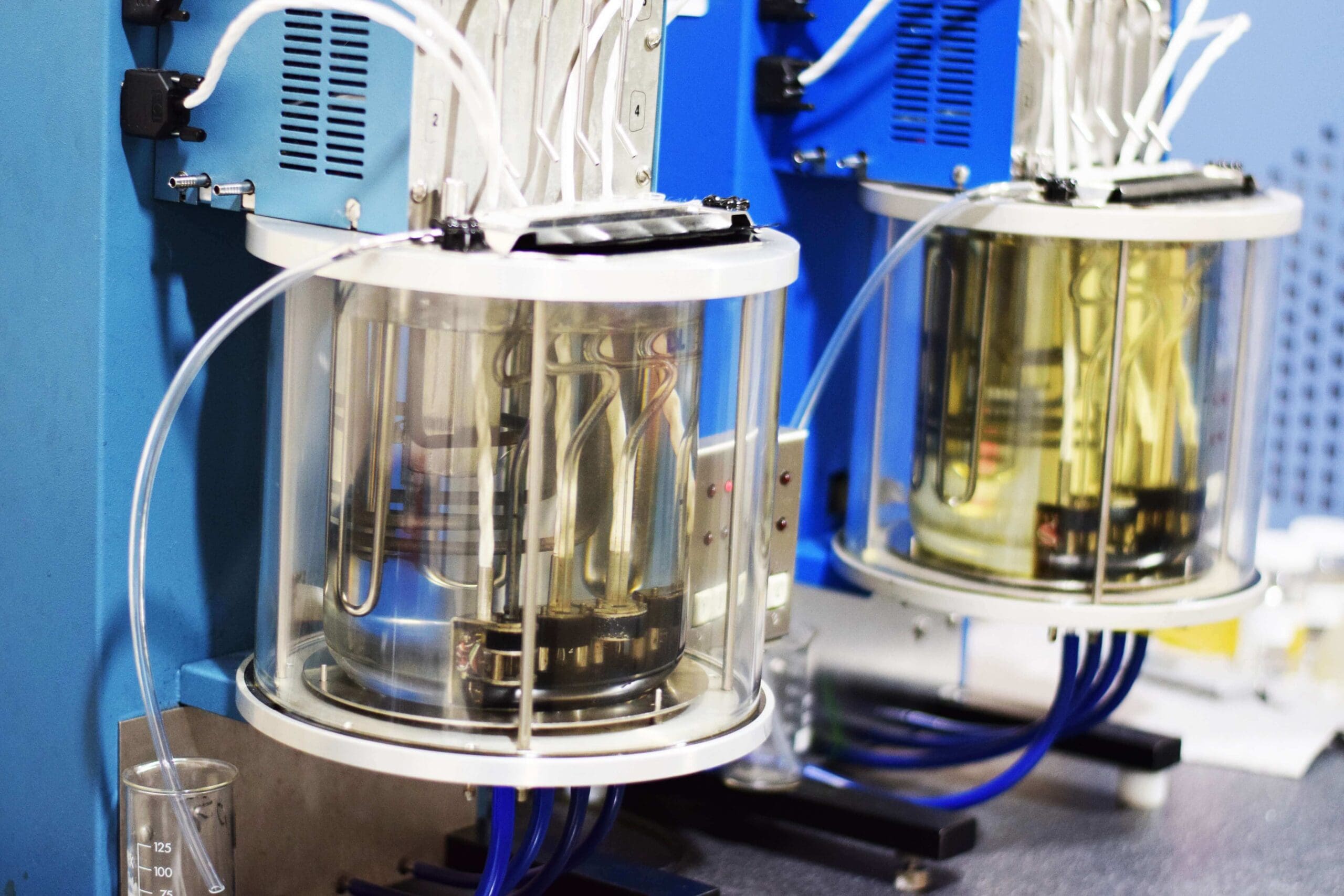

Independent Laboratory

We have our own oil analysis laboratory, which allows us to manage all aspects of this service.

Expert Insight

We are driven by engineering performance to ensure our specialist engineers and technicians provide the insights and solutions that make a difference to our customers.

Asset Focussed

We can assist with procurement, but our main goal is to help you achieve the lowest "through-life" cost for your assets.

Frequently asked questions

How often should a lubrication survey be conducted?

It is recommended that a lubrication survey is conducted annually but you will also need to consider the type of equipment, the operational environment, and the current maintenance practices.

What are the different types of methods used in a lubrication survey?

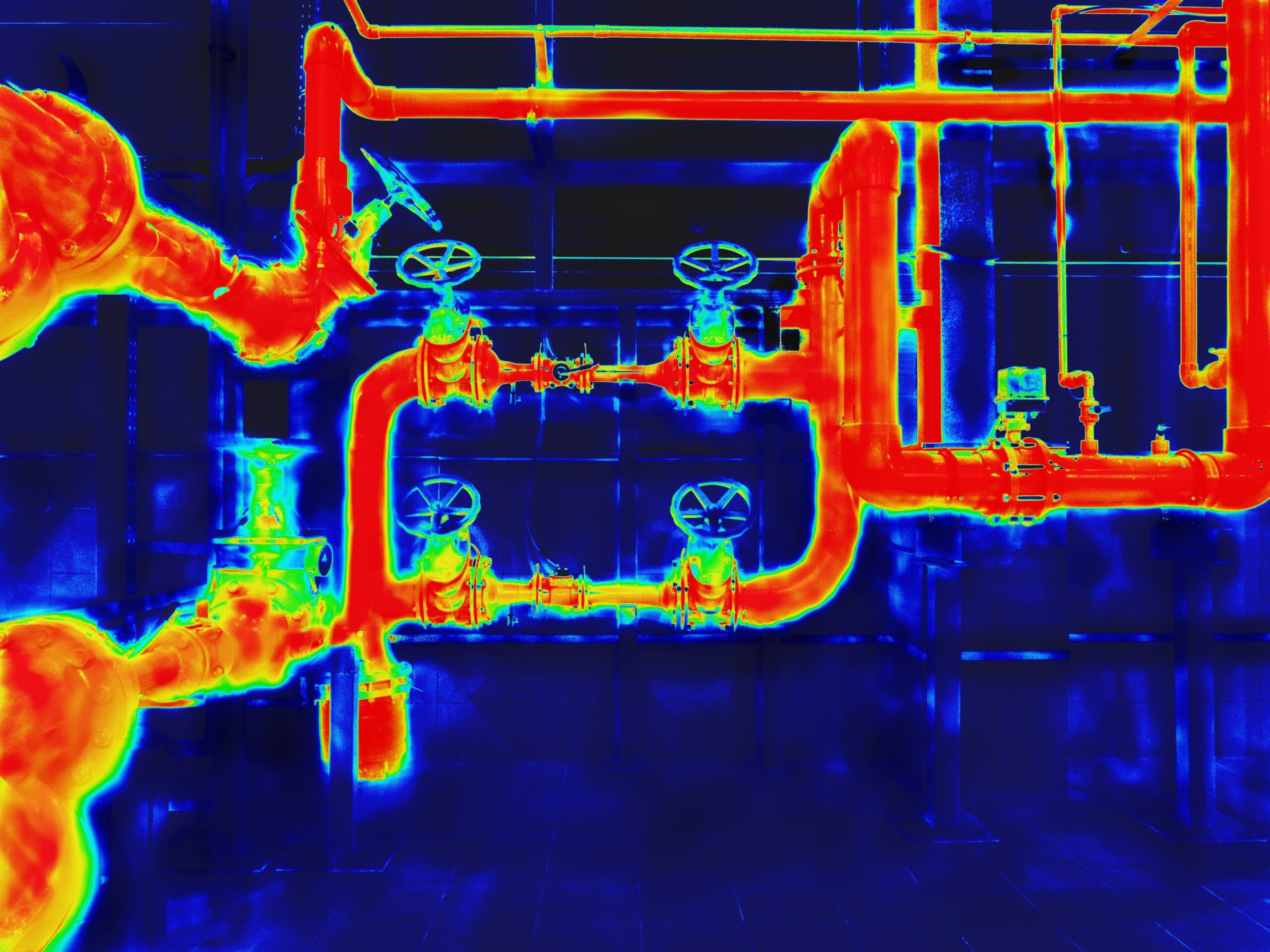

The method used during a lubrication survey will be based on the equipment and the goals of the survey. Here are the most common methods: Asset inspection, Filter debris analysis, Filtration Oil and grease analysis, Thermography, Training, Ultrasound, Vibration Analysis

Why are Lubrication Surveys important?

Sometimes the wrong type of oil is used. Other times, the oil is not applied correctly. And sometimes, the equipment is not kept clean. Optimised lubrication is about preventing these problems from happening. It’s about putting the right systems in place to ensure that equipment is always properly lubricated. If you want to improve the reliability and performance of your equipment, optimised lubrication is a must.

Let's talk about Lubrication Surveys

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Five Benefits Of Taking A Vibration Analysis Course For You And Your Business

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team