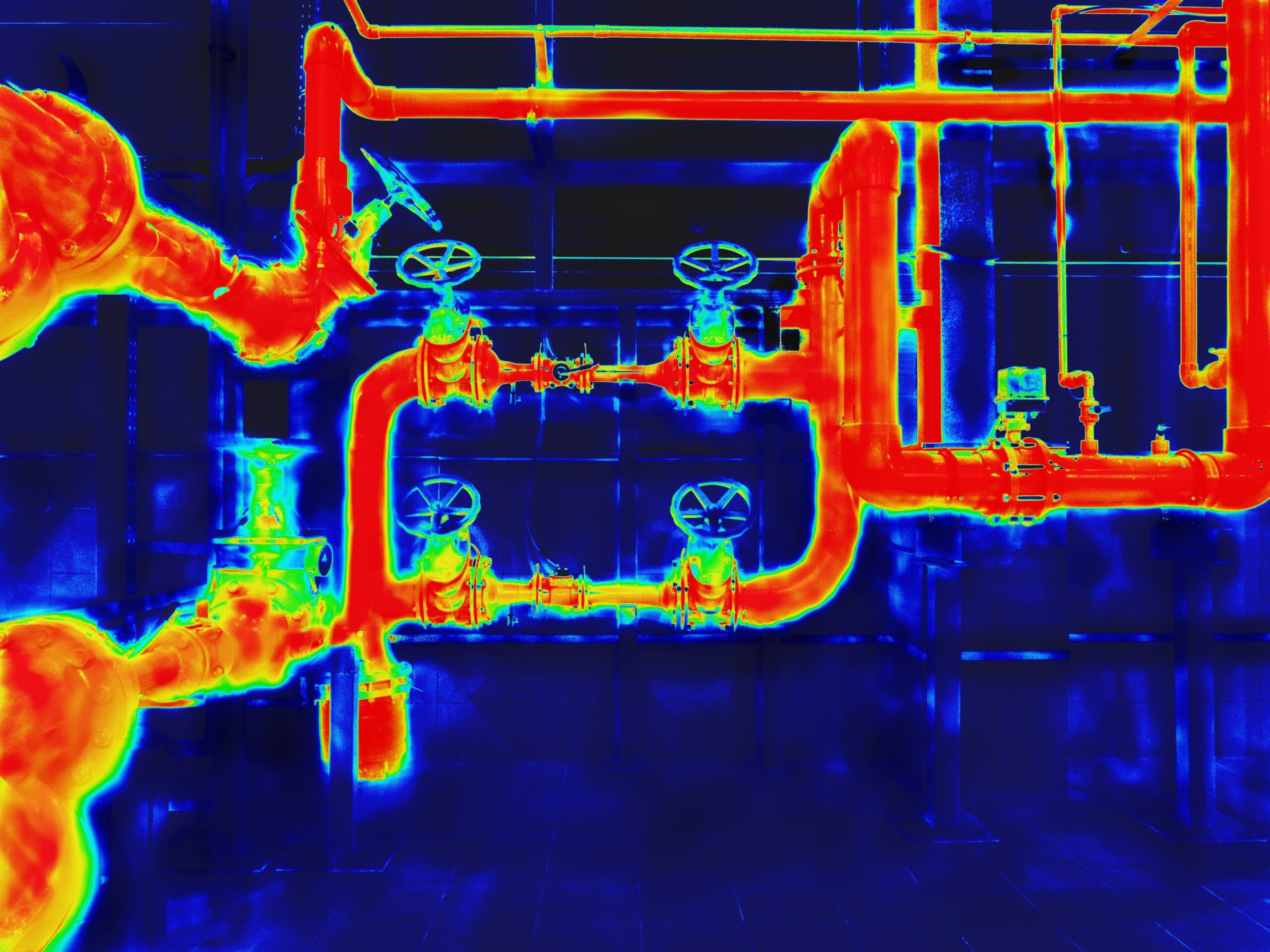

Condition Monitoring

Vibration Analysis

Vibration Analysis addresses excessive vibrations, noises, or inefficiencies, we prevent breakdowns. We can help you optimise performance, ensuring reliability and a longer lifespan for your equipment.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Vibration Analysis?

If you are experiencing any issues with your assets and equipment, it is important to have your equipment inspected by a qualified vibration analyst.

Vibration analysis can help to identify the underlying problem and prevent further damage to the machine. Our advanced vibration analysis services can help you effectively monitor the condition of your industrial equipment.

Used as a non-destructive testing method, Vibration Analysis can be used to identify and diagnose hidden problems in your rotating machinery. Not only is it a valuable tool for improving the reliability and lifespan of your equipment, but it can also enable you to implement a targeted maintenance strategy that support your long term operations.

Who we've partnered with...

Key benefits

Early detection of potential issues

By identifying deviations in vibration data, you can take proactive measures to prevent potential issues, saving you valuable time and money in the long run.

Scheduled maintenance

By identifying potential problems early on, you can prioritise and plan maintenance activities effectively, minimising the risk of unplanned downtime.

Prevent costly repairs and downtime

By identifying problems early on, it is possible to take corrective action before they cause major damage, saving you money and helping to avoid unnecessary downtime.

Extend equipment lifespan

By identifying and correcting problems early on, it is possible to extend the life of your critical equipment.

Let's talk about Vibration Analysis

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you?

We can support you with your requirements, no matter what they might be. Just some of the ways we can do this, include:

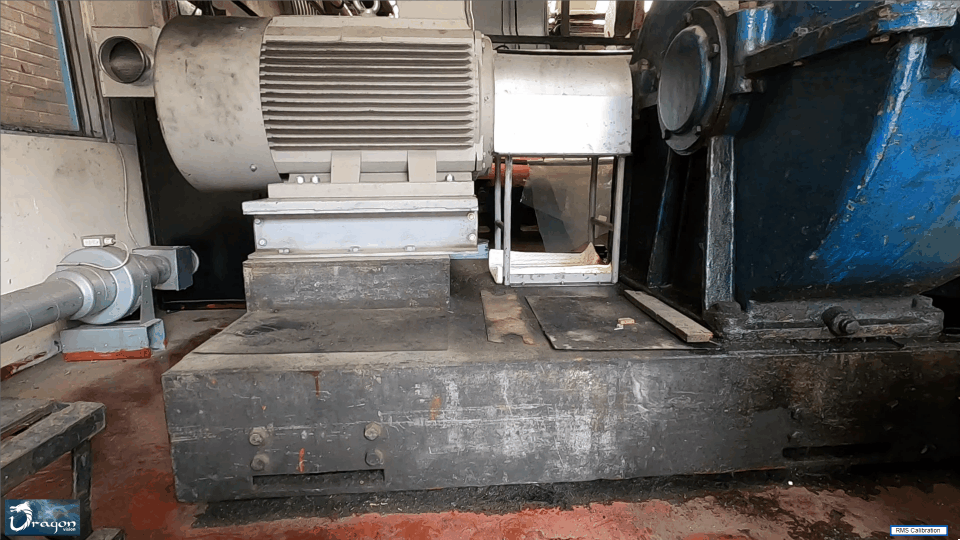

Vibration Data Collection

Our skilled reliability engineers use sensors and equipment to collect vibration data from your machinery. We ensure precise measurements.

Data Analysis and Interpretation

Our Remote Diagnostics Team analyses vibration data using advanced software and tools to identify defects or abnormalities.

Fault Diagnosis and Reporting

We diagnose the root causes of vibration anomalies and provide actionable recommendations to help you prioritise and plan maintenance activities.

Long-term Trend Monitoring

We track equipment performance trends over time with ongoing vibration monitoring services. By comparing current data to historical records, we identify any deviations and take proactive measures to prevent potential issues.

Our Solutions

Speak to us about the processBES Group can support the needs of your business in many ways, from commissioning to troubleshooting and many more.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Training centre & academies

Our very own internal training academies, ensures high standard.

Frequently asked questions

How is vibration analysis conducted?

The process for conducting vibration analysis involves a number of steps:

- Data collection: An engineer will collect vibration data from the machinery.

- Data processing: The data that is collected is then processed to remove noise and artefacts.

- Data analysis: Once the data has been processed, it can the be analysed to identify potential problems.

- Fault diagnosis: The results of the data analysis are then used to diagnose the underlying problem.

- Corrective action: Any problems that have been identified through the analysis can then be rectified.

What are the different types of vibration analysis?

There a lots of different types of vibration analysis. Each of them have their own benefits and disadvantages.

Here are some of the most common types:

- Trend analysis

- Spectral analysis

- Modal analysis

How often should vibration analysis be conducted?

To determine the required frequency of vibration analysis, you will need to consider a number of factors: the type of machinery, the operating conditions and the risk of failure.

If you own or operate critical machinery, the frequency advised will be more regular, possibly on a monthly or quarterly basis.

For less critical machinery, it might be more appropriate to conduct vibration on an annual or bi-annual basis.

Who is qualified to carry out vibration control monitoring?

Today, there are various levels of PCN’s available for company employees in which to gain accreditation. To progress through the PCN levels, you need to accumulate a required amount of experience, attend accredited training courses and then pass professional examinations. All of our vibration analysts have this experience, training and qualifications.

Why do you need a certificate of competence in vibration condition monitoring?

It identifies the individual’s competence in condition based predictive maintenance.

The qualification also facilitates compliance with ISO 9001:2015 Quality Management Systems for training & personal qualification.

What are the applications of Vibration Analysis?

Here is a list of the most popular tests and failures:

Tests:

- Bearing Failure

- Phase Analysis

- Time Waveforms

- Resonance

- Critical Speeds

- Misalignment

- Looseness

- Drive Belts

- Gearboxes

- Electrical

- Generator

Failures:

- Wear and lubrication faults

- Unbalance, bent shafts and cocked bearings

- Worn/damaged gear teeth

- Bump tests

- Run up, coast down

- Dynamic (i.e. with machine running)

- Structural, internal and external

- Wear and misalignment

- Gear and bearing faults

- AC and DC motors and electrical supply faults

- Shorted rotor turns (thermal growth)

Let's talk about Vibration Analysis

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Power and Utilities

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Retail

Explore sector

Renewables

Explore sector

Rail

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Five Benefits Of Taking A Vibration Analysis Course For You And Your Business

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team