Condition Monitoring

Ultrasonic Condition Monitoring

Ultrasonic Condition Monitoring detects ultrasonic frequencies, pinpointing issues like bearing wear, gear misalignment, or rotating machinery defects for precise solutions and smooth operations.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

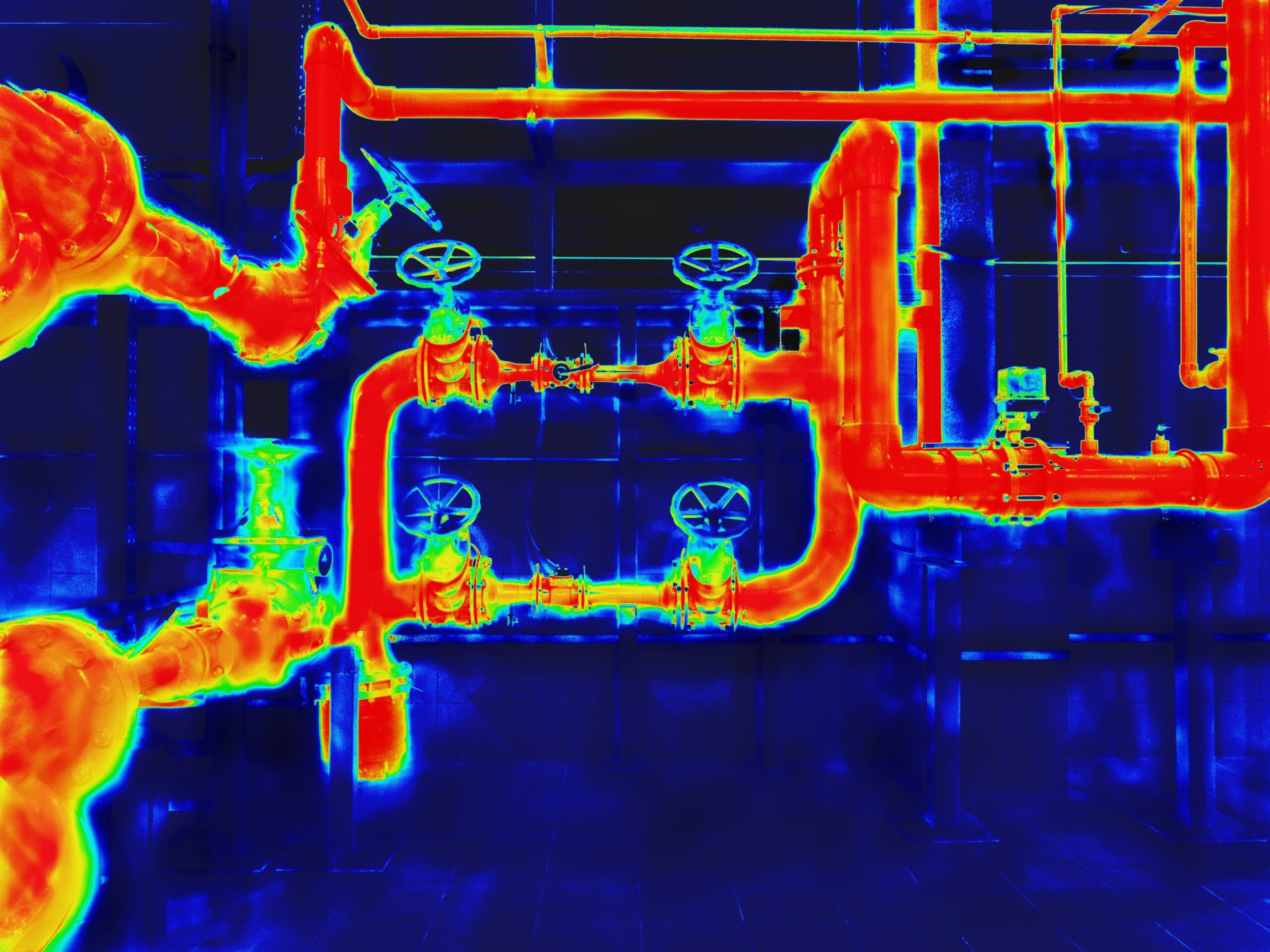

What is Ultrasonic Condition Monitoring?

If you’re grappling with issues like bearing, gear, or rotating machinery defects, our non-destructive testing (NDT) method utilises high-frequency sound waves to pinpoint material and structural flaws.

Specialising in early defect detection for bearings, gears, and rotating equipment, our services are a preventive measure against costly failures, ensuring equipment safety. For comprehensive asset monitoring, we recommend combining ultrasound and vibration technologies to detect multiple failure modes.

Our offerings include airborne and structure-born ultrasonic condition monitoring, covering everything from compressed air/gas leak detection surveys to bearing monitoring and steam trap surveys.

Who we've partnered with...

Key benefits

Early detection

Early detection Ultrasound provides early warning indications of failure conditions.

Solve problems

Ultrasound will detect lack of lubrication and prevent over lubrication.

Flexible technology

Ultrasound instruments support other technologies.

Let's talk about Ultrasonic Condition Monitoring

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we’ll work with you?

At BES Group, we seamlessly integrate ultrasonic condition monitoring with other technologies, offering flexible contracted or pay-as-you-go services.

Proactive Maintenance

Our proactive approach allows for targeted interventions, preventing potential breakdowns and optimising the overall performance of your machinery.

Emergency & Ad-Hoc Services

With engineers strategically located across the UK, we provide emergency or ad-hoc ultrasonic response services, leveraging years of experience to deliver key monitoring, corrective, and engineering solutions during critical times.

Trust BES Group to elevate your maintenance strategy with Ultrasonic Condition Monitoring, ensuring operational excellence and minimising the risk of unplanned, costly downtime.

Our process

Speak to us about the processFrom initial planning to results that matter, BES Group will be with you at every step

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Training centre & academies

Our very own internal training academies, ensures high standard.

Let's talk about Ultrasonic Condition Monitoring

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Power and Utilities

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Rail

Explore sector

Renewables

Explore sector

Retail

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Five Benefits Of Taking A Vibration Analysis Course For You And Your Business

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team