Condition Monitoring

Thermographic Surveys

Thermographic Surveys detect hidden faults early, preventing failures and minimising downtime. Identify issues like bearing failures, misalignment, and circuit overloads to keep operations running smoothly.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is a Thermographic Survey?

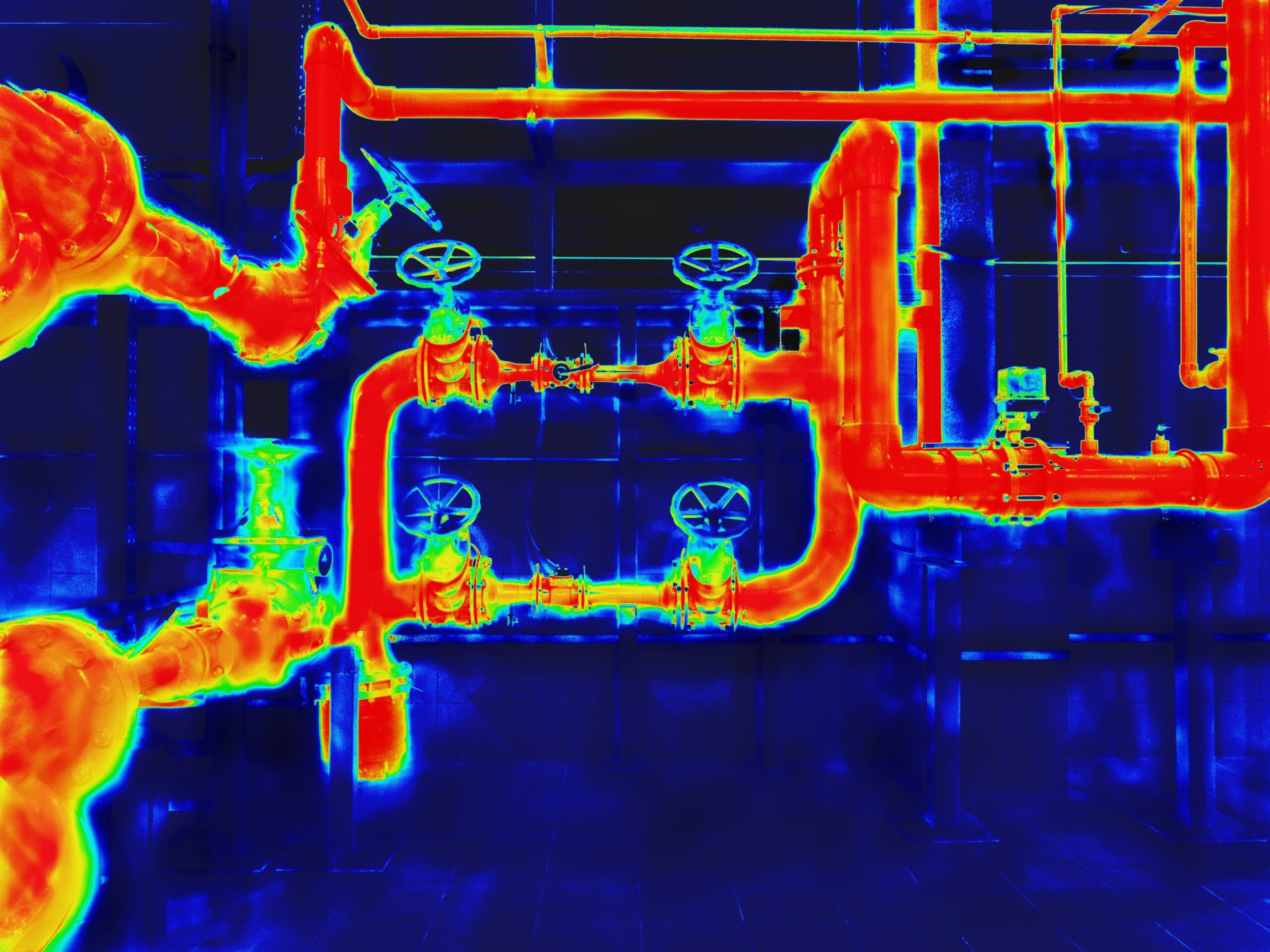

Thermographic Surveys are a type of asset reliability inspection, which primarily assess electrical and mechanical equipment. They can also be applied to buildings, assets, and refractory and process applications.

Thermographic Surveys detect issues that may be difficult to see, which can help you ensure your equipment and assets are in good working order and operating safely. Thermographic building surveys are also useful for maintaining compliance with Building Research Establishment Environmental Assessment Methodology (BREEAM) certifications, making sure your building meets regulations and environmental performance standards.

Who we've partnered with...

Key benefits

Early detection of issues

Thermographic Surveys can detect potential hazards, such as electrical fires, gas leaks, and structural defects early, helping you prevent accidents.

Electrical efficiency

Electrical thermographic surveys can identify areas of heat loss, allowing you to make greater energy savings and reduce costs.

Quick and accurate

Our surveys can be conducted quickly and easily without prior inspection or preparations.

Minimal downtime

Your assets and equipment stay fully operational while we conduct our surveys.

Non-invasive

Our surveys are non-invasive and won’t damage your assets or equipment.

Detailed report

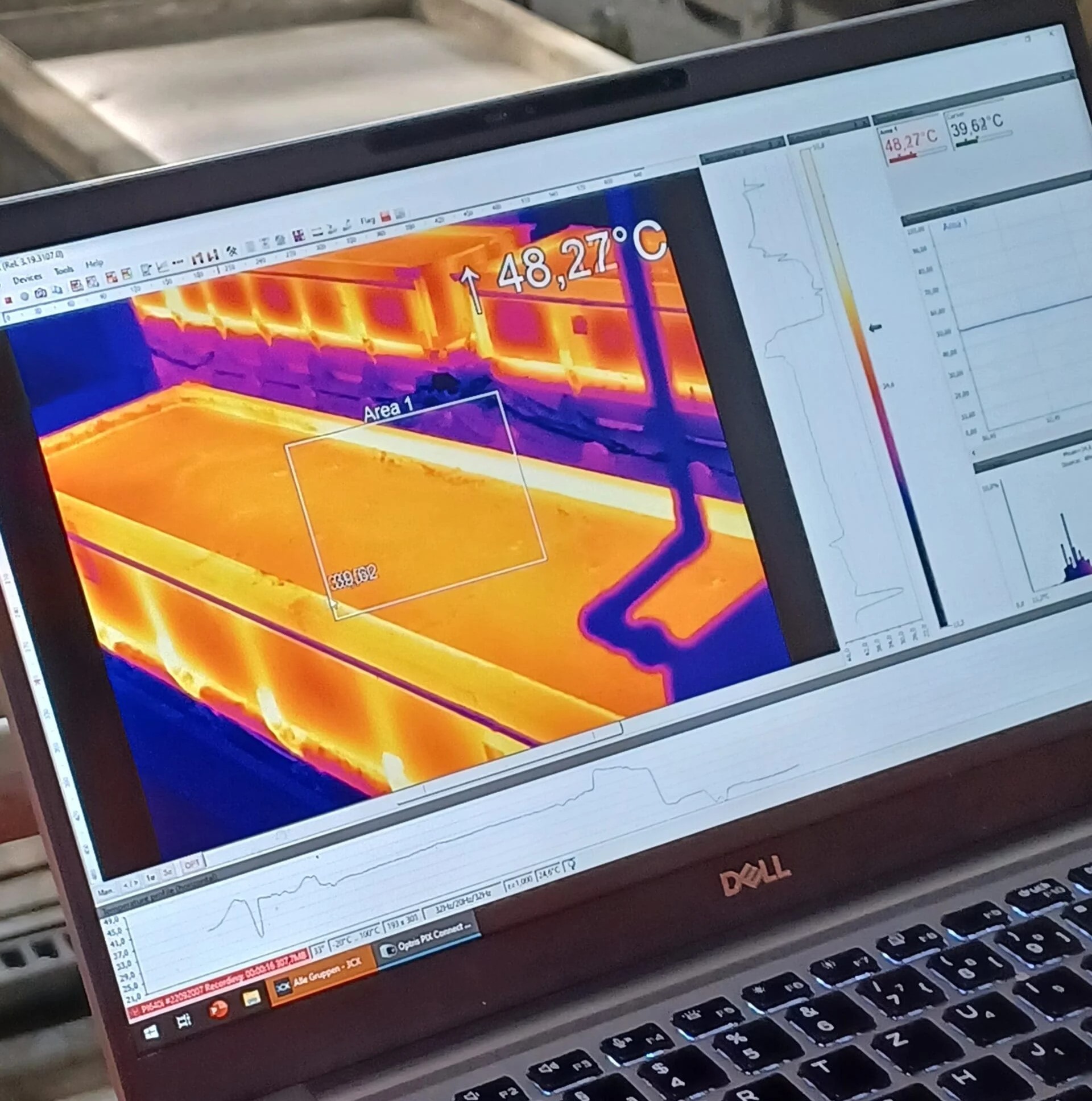

You’ll receive a detailed Thermographic Survey report with actionable steps, which is available for you to access online whenever you need it.

Let's talk about Thermographic Surveys

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Our Electrical, Building, and Mechanical Surveys

Our Electrical, Building, and Mechanical Surveys use infrared technology to detect faults, improve efficiency, and prevent costly failures.

Electrical Surveys

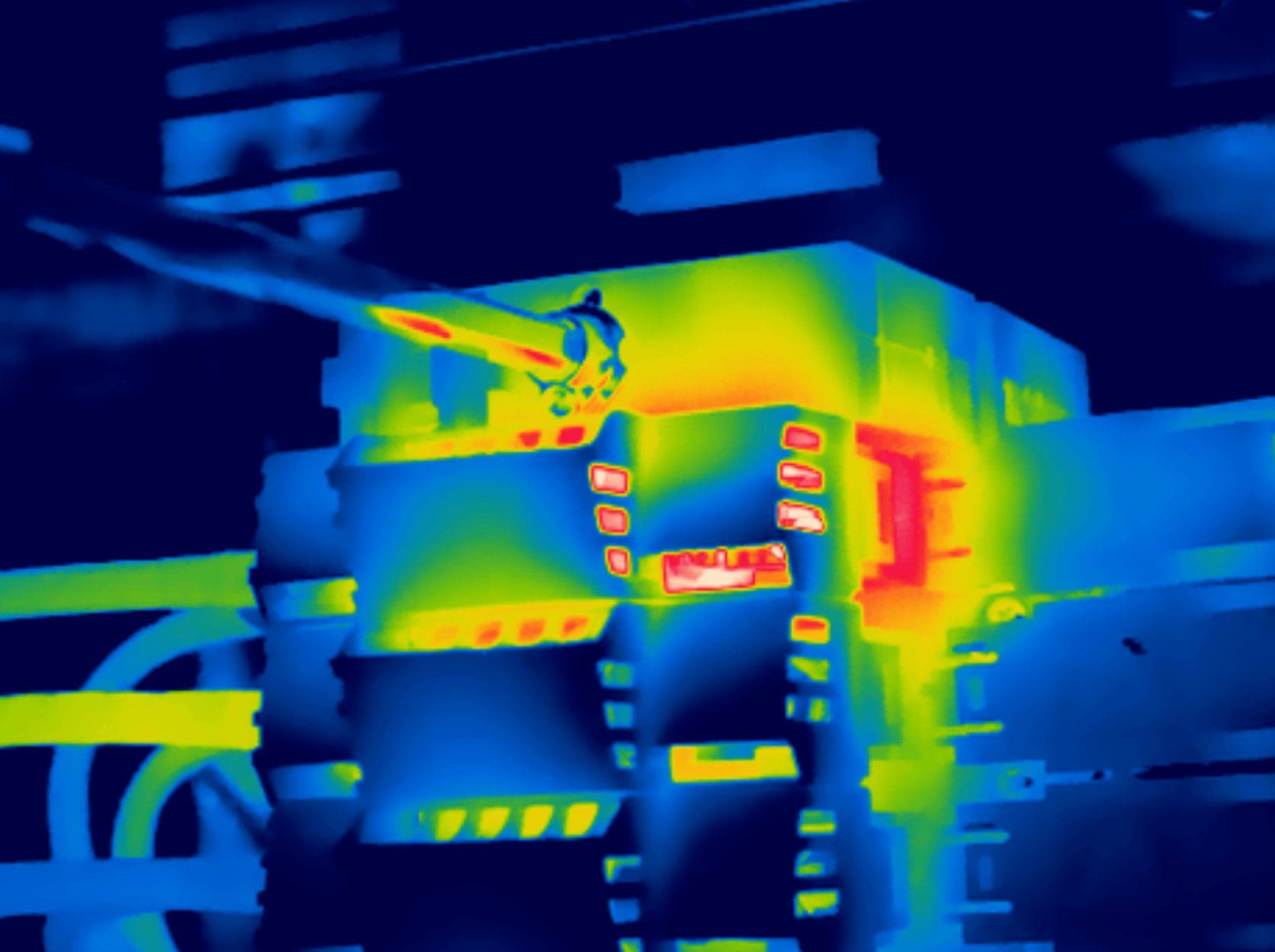

Electrical Thermal Imaging Surveys are a non-invasive, highly effective method for detecting potential electrical hazards. These surveys use a thermal imaging camera, which measures the surface temperature of electrical components and rewiring.

Building Surveys

Thermographic Building Surveys use infrared cameras to assess the surface temperature distribution of a building and identify potential heat loss or gain areas.

Mechanical Surveys

Mechanical Thermal Imaging Surveys utilise infrared cameras to capture images of surface temperature distribution on mechanical equipment.

Our process

Speak to us about the processDiscover how we deliver the best results for our clients with our Thermographic Survey process

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Training centre & academies

Our very own internal training academies, ensures high standard.

Frequently asked questions

Is a Thermography Survey and Thermal Imaging the same?

Thermographic Surveys refer to the entire assessment process of inspecting electrical components and assets to detect abnormal temperatures. The survey also involves a detailed report with findings and actionable guidance. Thermal imaging is a technique used as part of the Thermographic Survey. It’s the process of capturing images that display temperature variations.

How often should you conduct a Thermography Survey?

The frequency of Thermographic Surveys depends the type of equipment or asset, and how often it is used. Generally, Thermographic Surveys should be carried out in between the period of formal inspections to identify potential issues. For example, every 1-3 years for buildings and at least once a year for electrical systems. In higher-risk environments such as areas that carry ATEX ratings, surveys may be required more frequently.

Is a Thermography Survey a legal requirement?

Despite Thermographic Survey’s not being regarded as a legal requirement in the UK, the global organisation National Fire Protection Association (NFPA) mandates that a Thermographic Inspection is conducted every 12 months, across all electrical equipment under standard 70B. Although, the NPFA do not hold legal power in the UK to enforce this. However, the HSE could choose to cite this along with the Electricity at Work Regulations 1989 in a claim if required.

What does BREEAM stand for?

BREEAM stands for Building Research Establishment Environmental Assessment Methodology. It sets the standards for building and works ratings. Maintaining compliance with BREEAM is important for ensuring your building meets regulations and environmental performance standards.

How many types of Thermography are there?

There are two main types of Thermography: Active Thermography: Which uses an external heat source to create a temperature difference. Passive Thermography: Which uses the natural heat emitted by the object being inspected. Using thermal imaging cameras, Thermographic Surveys identify potential hazards that may not be noticeable during a routine visual inspection. If left undetected, these hazards could be critical to your operations, causing issues such as gas leaks, overheating, faulty insulation, or blocked pipes – therefore it’s important to identify them as soon as possible. Thermographic Surveys can identify abnormal temperature distribution to detect faults early. Most assets have a spike in temperature (hot or cold) before they fail, which is why infrared cameras are so effective as they can spot temperature changes immediately.

What are some reasons for possible defects in electrical systems?

Equipment can have abnormally high temperatures for many reasons, including faulty insulation, overloaded sockets, loose connections, or legacy and outdated equipment. Gradual wear and tear over time can also increase the risk of higher temperatures and may lead to equipment failure. For example, distribution boards are commonly susceptible to overloaded electrical circuits – leading to a surge in temperature. Without proper detection and diagnosis, equipment could continue to operate at high temperatures, leading to severe safety risks such as accidents and fires. Thermographic Surveys help to identify hazards early, so they can be repaired or replaced before they cause further risks and create unplanned downtime.

What types of issues can Electrical Surveys identify?

Electrical Surveys can detect various potential faults, including:

- Poor connections: Loose or corroded connections generate excess heat due to increased resistance.

- Overloaded cables: Carrying more current than rated can cause overheating, leading to insulation damage, arcing, or fires.

- Faulty electrical equipment: Transformers, junction boxes, and other equipment may overheat due to internal malfunctions.

- Hidden hazards: Thermal imaging can uncover overheating cables concealed behind walls or enclosed spaces.

Regular electrical surveys help identify these issues early, preventing failures and improving safety.

What can Building Surveys detect?

Building Surveys use infrared imaging to identify:

- Heat loss and gain areas: Pinpoint where heat is escaping or entering to improve ventilation efficiency.

- Building envelope performance: Assess insulation effectiveness to minimize energy consumption and maintain optimal indoor temperatures.

- Air leaks and gaps: Detect drafts around windows, doors, and other structures to enhance airtightness and energy efficiency.

These surveys help improve building performance, reduce energy costs, and enhance overall comfort.

What issues can Mechanical Surveys identify?

Mechanical Surveys help detect potential faults by analysing temperature variations, including:

- Bearing failures: Excessive heat indicates friction or wear between bearing surfaces.

- Misalignment: Uneven temperature distribution can signal friction and vibration issues.

- Damaged belts: Heat buildup may suggest worn or mismatched belts causing friction with pulleys.

Early detection of these issues helps prevent breakdowns, reduce downtime, and extend equipment lifespan.

Let's talk about Thermographic Surveys

Send one of the team a message

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Power and Utilities

Explore sector

Rail

Explore sector

Renewables

Explore sector

Retail

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Five Benefits Of Taking A Vibration Analysis Course For You And Your Business

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team