Condition Based Maintenance

CBM Corrective Services

Quickly identify issues and apply tailored corrective measures with our Condition Based Maintenance Corrective Services. We help clients ensure optimal equipment performance.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What are CBM Corrective Services?

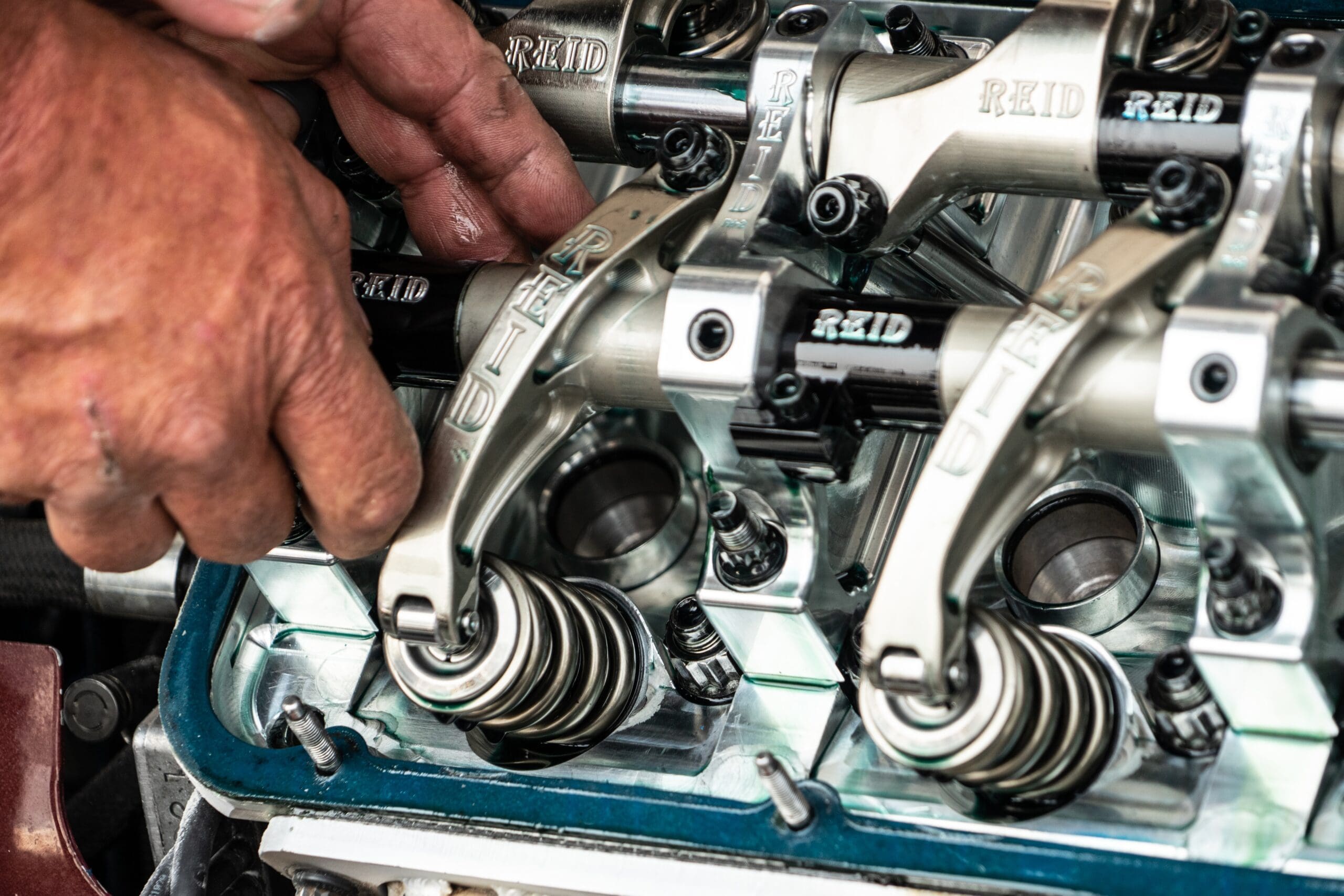

At BES Group, we specialise in precisely identifying and correcting issues affecting your machinery, offering a proactive approach to prevent downtime and mitigate potential damage. Our expert team leverages advanced diagnostics to pinpoint issues swiftly and applies tailored corrective measures, ensuring optimal performance of your equipment and safeguard your investments.

Our proactive approach ensures that your unique needs are not only met but exceeded. Whether it’s optimising performance, preventing downtime, or enhancing the overall reliability of your machinery, we have the knowledge and resources to tailor solutions to your specifications. Trust BES Group to be your strategic partner in maximising operational efficiency and minimising disruptions.

Who we've partnered with...

Key Benefits

Improved reliability

Corrective services can help to identify and correct problems that could lead to equipment failure. This can help to improve the reliability of equipment and reduce the number of unplanned outages.

Increased efficiency

Corrective services can help to identify and correct inefficiencies in the maintenance process. This can help to improve the efficiency of maintenance and reduce costs.

Enhanced safety

Corrective services can help to identify and correct hazards that could lead to accidents. This can help to improve the safety of workers and reduce the number of injuries.

Let's talk about CBM Corrective Services

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we’ll work with you

At BES Group, our team have the skill, expertise, and experience to address the challenges you’re facing, stemming from our commitment to elevating the reliability and uptime of your machines and assets.

Specialist Reliability Engineers

Our CBM Corrective Services team makes up a network of skilled reliability engineers across the UK, and our collective expertise and capabilities positions us as a leading provider of maintenance services. We pride ourselves on being a comprehensive solution provider, capable of delivering a spectrum of solutions seamlessly from a single point of contact. BES Group have the expertise and experience to help you overcome these challenges and improve the reliability and uptime of your machines or assets.

Why choose CBM Corrective Services?

CBM Corrective Services helps you determine the cause of an issue, and thereafter, apply a corrective solution. This reliability service is particularly beneficial if your equipment or machinery experiences the below issues:

High degree of asset failure after maintenance

This means that your machines or assets are failing shortly after they have been maintained. This can be a frustrating and costly problem.

Lack of industry standard datums for machinery setup

This means that there is no standard way to set up your machines or assets, leading to errors and misalignment, which can then cause premature failure.

Independent support requirements

This means that you have to rely on outside contractors for maintenance and support. This can be a challenge and costly, especially if you have machines or assets in remote locations.

Restricted internal engineering resources

This means that you don’t have the in-house engineering expertise to properly maintain your machines or assets, potentially leading to problems down the road and reducing operational efficiency.

CBM Corrective Services process

Speak to us about the processWe understand that these challenges can be daunting, but we want to assure you that we are here to help. We can help you to:

Let’s talk. Ask us anything.

Send one of the team a message

Why Choose BES Group?

Accredited Assurance

You can be confident that our services will be conducted to the highest standards, as we hold a number of accreditations that demonstrate our commitment to quality.

Flexible and Responsive

We have a team of reliability engineers located across the UK, so we can respond quickly to your needs and provide you with the most cost-effective solution.

Data-Driven

We use a multi-technology approach to ensure that our corrective actions are effective and that your assets are operating to their full potential.

Frequently asked questions

When should CBM Corrective Services be performed?

CBM Corrective Services should be performed when there is evidence that a machine or asset may not be operating correctly. There may be several signs:

- Increased vibration levels

- Abnormal noise

- Increased heat

- Decreased performance

- Oil leak

- Visual signs

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Five Benefits Of Taking A Vibration Analysis Course For You And Your Business

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team