Asset Reliability

Condition Based Maintenance

Prevent unexpected downtime of business critical assets. At BES Group, our comprehensive Condition Based Maintenance (CBM) service works with your business to audit and evaluate the efficiency of crucial assets and machinery.

Explore our services

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with...

What is condition Based Maintenance?

Condition Based Maintenance is considered a form of asset management. CBM utilises real-time data taken from the condition of your assets, to create an informed asset maintenance strategy. This is a proactive maintenance strategy that aims to identify potential issues before they arise and negatively impact your business.

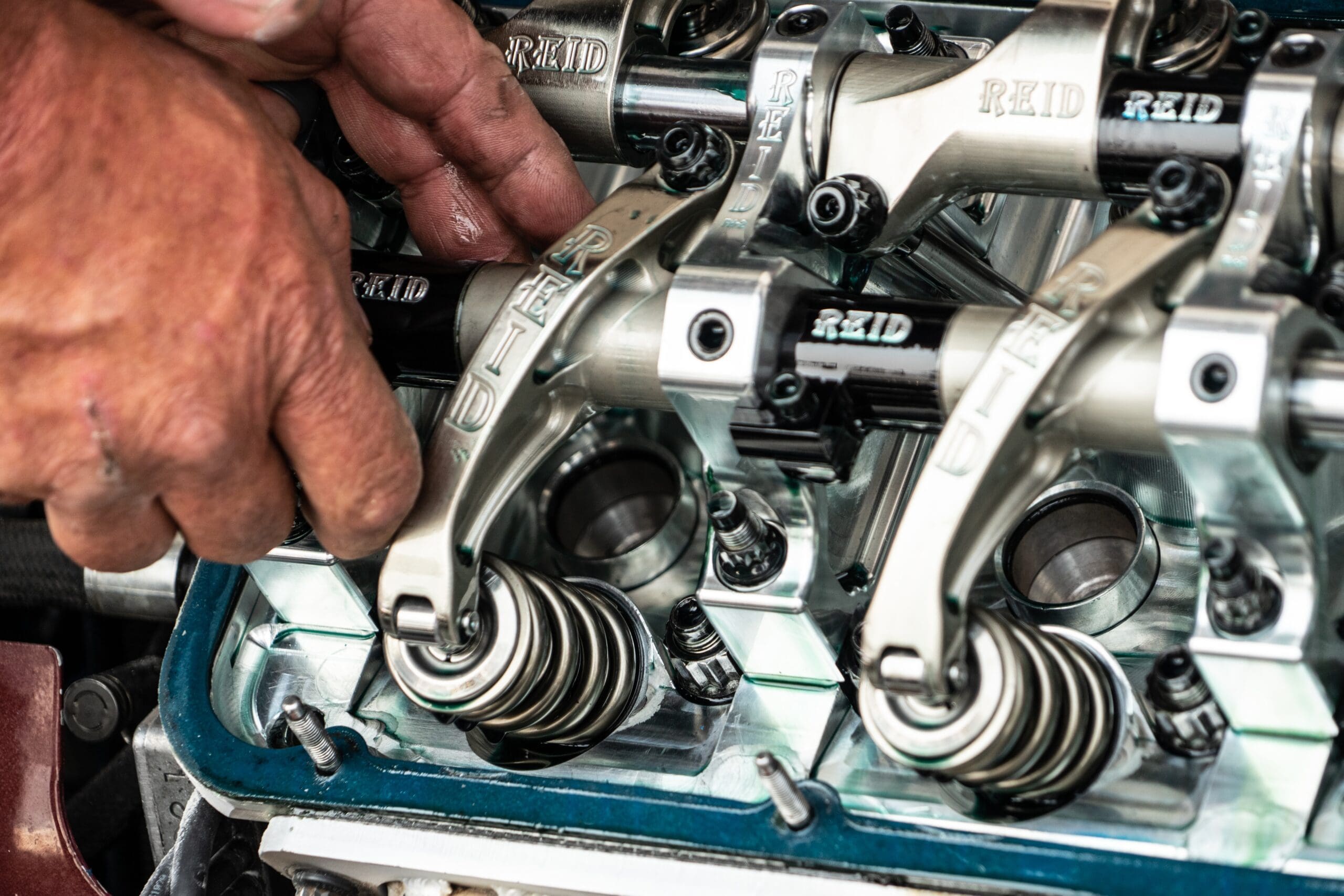

CBM Corrective Services

We use advanced diagnostics to quickly identify issues and apply tailored corrective measures, ensuring optimal equipment performance and protecting your investments.

Laser Alignment

This service ensures that rotating equipment is precisely aligned, reducing wear and tear, improving efficiency, and extending the life of your machinery.

In-Situ Balancing

This involves adjusting the balance of rotating machinery while it’s still in operation, reducing vibrations and preventing premature failure.

Let's talk about Condition Based Maintenance

Send us an enquiry

Not seeing what you expected?

Try using our search

Explore what our clients say

Our Condition Based Maintenance Process

Found out more about our processDepending on your business requirements, our certified team of engineers can apply a variety of advanced technological methods to accurately determine the condition of your assets.

Our process may include:

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Healthcare

Explore sector

Hospitality and Leisure

Explore sector

Insurance

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Power and Utilities

Explore sector

Retail

Explore sector

Renewables

Explore sector

Rail

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Condition Based Maintenance, from BES Group

Explore all sub-services- Why is Condition Based Maintenance necessary?

- Why choose our data driven insights?

- What are the benefits of an adaptive maintenance approach?

- What do our technology applications help to identify?

- What are the key benefits of Condition Based Maintenance?

We monitor the condition of your equipment and identify potential issues using advanced technology, to provide data driven insights and analysis. CBM ensures your equipment is reliable and safe to use, while reducing unscheduled downtime.

Condition-Based Maintenance is necessary to ensure that equipment operates efficiently and reliably. By detecting potential issues early, CBM helps prevent unexpected failures, reduces downtime, and extends the lifespan of machinery. It also enhances safety and reduces maintenance costs by addressing problems before they escalate.

Our CBM services incorporate industry expertise, innovative technology, consultancy, and data analysis to indicate when an impacted part of an asset may fail. When potential wear or faults are detected, this allows you to schedule necessary repairs or replacements at your convenience.

Key insights from the data we provide includes:

- Identification of root causes for asset issues.

- Recommendations for appropriate maintenance actions.

- Prioritisation of corrective actions based on severity.

- Clear instructions and guidance for implementing corrective actions.

Receive convenient data-driven insight that enables:

- Real-time asset performance dashboards provide a quick overview of asset health and potential issues.

- Trend analysis and predictive modelling identify emerging trends that may indicate impending failures.

- Comprehensive asset health reports provide detailed information on asset performance across multiple dimensions.

- Integration with existing EPM systems ensures seamless data integration and reporting.

- Customisable views and filters allow you to tailor reports to your specific needs.

Data-driven insights: We analyse CBM data to identify areas for improvement, refine our recommendations, and optimise our predictive maintenance models.

Collaborative engagement: We actively engage with your team to gather feedback, identify specific challenges, and tailor our approach to their unique needs.

Technology integration: We leverage emerging technologies and data analytics to enhance the effectiveness of our CBM program, ensuring it remains at the forefront of innovation.

Tailored solutions: We continuously refine our CBM program to address evolving industry standards, regulatory requirements, and your specific plant operations.

Vibration analysis: Detects subtle changes in machinery operation, indicating potential wear and tear or misalignment.

Infrared thermography: Identify heat signatures that indicate potential overheating, excessive friction, or bearing failure.

Ultrasonics: Pinpoints defects in rotating machinery components, such as cracks, excessive wear, or loose bearings.

Oil analysis: Provides insights into fluid condition, contamination levels, and the presence of contaminants that can lead to premature failure.

Prevent unplanned downtime

Detect potential issues before they lead to failures, by monitoring the condition of equipment with real-time data to significantly reduce unexpected downtime.

Reduce unnecessary cost

Regular monitoring and timely maintenance can reduce unprecedented costs, as issues are addressed before they escalate into expensive repairs or replacements.

Improve reliability and efficiency

Our CBM solutions enhance the reliability of your machinery, leading to more consistent performance, a reduced risk of sudden breakdowns and improving productivity.

Increase machinery lifespan

By maintaining optimal operating conditions and preventing excessive wear, CBM extends the lifespan of your equipment while reducing energy consumption.

-

Why is Condition Based Maintenance necessary?

We monitor the condition of your equipment and identify potential issues using advanced technology, to provide data driven insights and analysis. CBM ensures your equipment is reliable and safe to use, while reducing unscheduled downtime.

Condition-Based Maintenance is necessary to ensure that equipment operates efficiently and reliably. By detecting potential issues early, CBM helps prevent unexpected failures, reduces downtime, and extends the lifespan of machinery. It also enhances safety and reduces maintenance costs by addressing problems before they escalate.

-

Why choose our data driven insights?

Our CBM services incorporate industry expertise, innovative technology, consultancy, and data analysis to indicate when an impacted part of an asset may fail. When potential wear or faults are detected, this allows you to schedule necessary repairs or replacements at your convenience.

Key insights from the data we provide includes:

- Identification of root causes for asset issues.

- Recommendations for appropriate maintenance actions.

- Prioritisation of corrective actions based on severity.

- Clear instructions and guidance for implementing corrective actions.

Receive convenient data-driven insight that enables:

- Real-time asset performance dashboards provide a quick overview of asset health and potential issues.

- Trend analysis and predictive modelling identify emerging trends that may indicate impending failures.

- Comprehensive asset health reports provide detailed information on asset performance across multiple dimensions.

- Integration with existing EPM systems ensures seamless data integration and reporting.

- Customisable views and filters allow you to tailor reports to your specific needs.

-

What are the benefits of an adaptive maintenance approach?

Data-driven insights: We analyse CBM data to identify areas for improvement, refine our recommendations, and optimise our predictive maintenance models.

Collaborative engagement: We actively engage with your team to gather feedback, identify specific challenges, and tailor our approach to their unique needs.

Technology integration: We leverage emerging technologies and data analytics to enhance the effectiveness of our CBM program, ensuring it remains at the forefront of innovation.

Tailored solutions: We continuously refine our CBM program to address evolving industry standards, regulatory requirements, and your specific plant operations.

-

What do our technology applications help to identify?

Vibration analysis: Detects subtle changes in machinery operation, indicating potential wear and tear or misalignment.

Infrared thermography: Identify heat signatures that indicate potential overheating, excessive friction, or bearing failure.

Ultrasonics: Pinpoints defects in rotating machinery components, such as cracks, excessive wear, or loose bearings.

Oil analysis: Provides insights into fluid condition, contamination levels, and the presence of contaminants that can lead to premature failure.

-

What are the key benefits of Condition Based Maintenance?

Prevent unplanned downtime

Detect potential issues before they lead to failures, by monitoring the condition of equipment with real-time data to significantly reduce unexpected downtime.

Reduce unnecessary cost

Regular monitoring and timely maintenance can reduce unprecedented costs, as issues are addressed before they escalate into expensive repairs or replacements.

Improve reliability and efficiency

Our CBM solutions enhance the reliability of your machinery, leading to more consistent performance, a reduced risk of sudden breakdowns and improving productivity.

Increase machinery lifespan

By maintaining optimal operating conditions and preventing excessive wear, CBM extends the lifespan of your equipment while reducing energy consumption.

Condition-Based Maintenance FAQs

How can issues arise without CBM?

For example, if an essential machine is operating on a continuous cycle 7 days a week, and there was a part of the machine that was unknowingly starting to fail, this could have a negative impact on the entire asset.

- This could lead to issues such as poor efficiency from the machine, frequent repairs or pauses in the operating cycle.

- The deteriorating part could unknowingly impact other parts of the machine, resulting in total machine failure.

- Without warning, this means a vital asset is taken out of production until a replacement arrives.

- Not only will the downtime of waiting for a new asset impact efficiency, but there is a greater cost associated with replacing a full asset opposed to a singular part.

- This could result in a pause in production for your business, resulting in delays, a loss of income and unsatisfied customers.

If an effective CBM strategy was implemented, this scenario could have been prevented. If your business has had a similar experience. Contact our team about implementing a CBM strategy today.

What are the different approaches to asset maintenance?

There are several different ways to incorporate asset maintenance into your business.

- Proactive maintenance: Condition Based Maintenance is a form of proactive maintenance. This takes into consideration how the asset operates and involves a comprehensive check of the asset; data is used to determine when or how maintenance is required.

- Predictive maintenance: This type of maintenance uses data to predict when a failure is likely to occur, allowing corrective action before it happens. Although sometimes this can result in parts that are in working condition being completely replaced, opposed to targeting the specific issue.

- Preventive maintenance: A scheduled maintenance program designed to prevent failures based on time or usage intervals, this typically includes responsibilities such as lubrication, cleaning, and inspection.

- Reactive maintenance: This type of maintenance fixes issues as they arise. It’s the least proactive and usually the most expensive, as typically an asset is run until it fails completely. The asset needs to be completely replaced, opposed to a singular part.

What is the difference between CBM and TBM?

CBM relies on monitoring the actual condition of equipment to schedule maintenance only when necessary. TBM (Time-based maintenance), also known as scheduled maintenance, involves performing maintenance at regular, predetermined intervals regardless of the equipment’s current condition. Condition Based Maintenance aims to prevent unexpected failures, while time-based maintenance is based on estimated usage and wear.

What is the difference between Condition Based Maintenance and corrective maintenance?

Condition-Based Maintenance focuses on preventing failures by monitoring equipment and addressing issues before they cause a breakdown. Corrective maintenance, conversely, is reactive. It involves fixing equipment after a failure or problem has occurred. CBM is proactive and preventative, while corrective maintenance is performed post-failure.

Where can Condition Based Maintenance be applied?

Condition-Based Maintenance is widely used in industries where equipment reliability and performance are critical. This includes:

- Automotive

- Aviation

- Manufacturing

- Energy

- Oil and gas

- Marine

- Chemical processing

- Healthcare

- Defence and military

- Food and beverage

How do I choose the right CBM solution for my business?

Our expert team can help advise you on the best CBM maintenance service for your business. We take into consideration all key aspects of your business, such as your industry and service, equipment and assets, and operating schedule. Our priority is to ensure that problems are identified early, to prevent unnecessary downtime and keep your assets and machinery running efficiently. Contact our team for a CBM consultation

What is included in an initial assessment?

Our comprehensive review covers: A tailored CBM strategy to align with your operating environment. Identify critical assets with highest maintenance demand. Reveal hidden maintenance costs and potential savings. Gap analysis between current practices and CBM implementation.

What happens during my site review?

During a site review, we identify assets that have high failure rates, complex operation conditions or significant environmental factors. We also identify any critical impacts on production output or overall plant performance. Our team also identify any prolonged downtime or high repair costs.

What training and support is offered to clients?

Our comprehensive training includes:

- Methods on how to utilise CBM data effectively.

- Identifying asset health and potential failure modes.

- Facilitating informed decisions and proactive corrective actions.

- Integrating CBM data into existing maintenance management processes.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Five Benefits Of Taking A Vibration Analysis Course For You And Your Business

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team