Destructive Testing

Laboratory Product Testing

Our Product Tests evaluate the quality, performance and safety of various products. This ensures quality compliance, and that mandatory specifications are met.

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Product Testing?

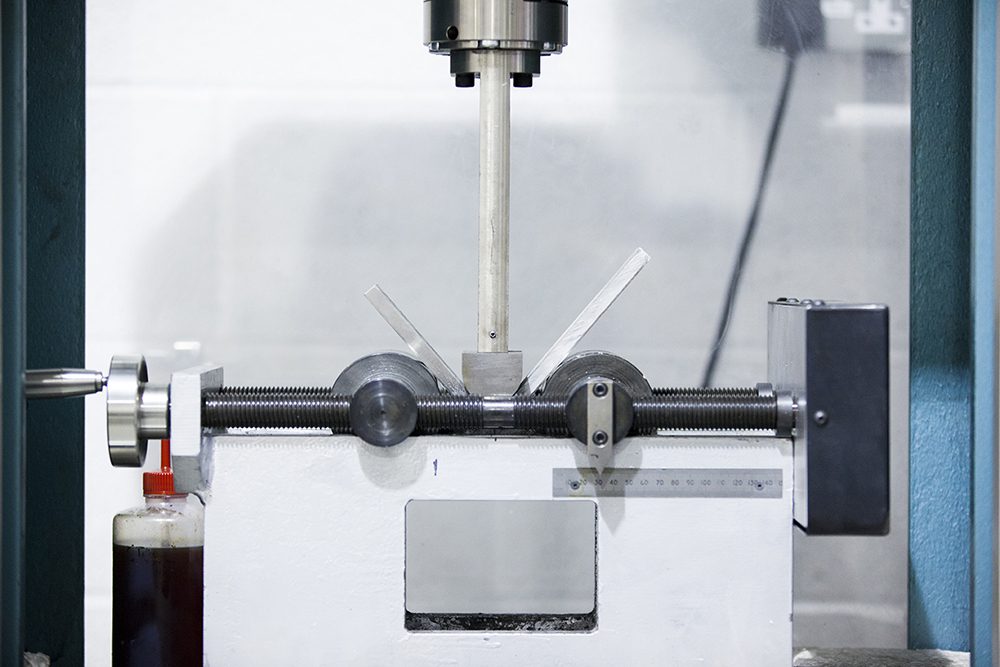

There are many ways to carry out Product Testing for safety and legal compliance. We carry out a range of mechanical, chemical and metallurgical assessments to confirm if a product is made of the right material, is suitable for it’s intended purpose, and also identify any potential flaws and defects before the product enters the market.

The basis for Product Testing is often an existing formal test method or product standard. Other testing situations, such as prototype testing may require a bespoke testing method to be developed to analyse the new product’s performance. Product Testing serves as a valuable tool for consumers, enabling them to make well-informed decisions, compare options, and choose products that align with their needs and expectations. It promotes transparency in the marketplace and encourages manufacturers to focus on delivering quality and value for money.

Who we've partnered with

Key benefits of Product Testing

Quality Compliance and Safety

For a product to be sold on the market, it must meet the necessary quality standards, comply with government regulations, and be suitable for its intended purpose.

Product Limitations

Conducting tests in the initial phases of product development enables manufacturers to obtain knowledge about the constraints of their products.

Innovation and Investment

Product testing results can play a pivotal role in obtaining patents for new inventions and innovations, and attract attention from potential investors.

Customer Satisfaction

Rigorous Product Testing prior to the product reaching a market guarantees that products meet customer expectations.

Let's talk about Laboratory Product Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Product Testing Services from BES Group

Product Testing helps consumers understand what to expect from a product. By providing objective data on features, functionality, and performance, consumers can make decisions based on their specific needs and preferences. When consumers have access to accurate and reliable information about a product’s capabilities, performance, and value, it empowers them to make informed purchasing decisions.

Reliable Product Testing Services

Product Testing can be carried out on a variety of goods, such as household and domestic products, or industrial products and components. We support clients across diverse industries with their Product Testing requirements. Some examples of products we have tested include:

- Hand tools and gardening equipment

- Barbeques and fireguards

- Saddlery and equestrian products

- Pet products and accessories

- Medical equipment

- Household items (e.g. ironing boards, cutlery and ladders)

- And much more!

Why is product testing important?

During the design and manufacturing process, it is essential to carry out product testing to make sure the product effectively fulfills these functional requirements and specifications. Product testing can also provide support regarding the quality and functionality of a product compared to existing offerings in the market. This aids in reducing the chances of failures and minimising potential health, safety, and legal consequences. It also offers essential guidance to consumers regarding the proper use of the product.We use a range of test methods for Product Testing, including:

Performance and Functionality Testing

Durability Testing

Reliability Testing

Safety Tests

Prototype Testing and Analysis

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

Decades of experience

Our team of expert inspectors have decades of experience in testing, and they have the expertise to identify and interpret the flaws in your materials.

Flexible service

We understand that our customers may require quick turnarounds and bespoke testing services, which is why we tailor all our services to suit your needs.

Destructive Testing Experience

Our team of expert inspectors have decades of experience in Destructive Testing method, and they have the expertise to identify and interpret the flaws in your materials.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Aerospace and Defence

Explore sector

Agriculture

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Consumer Products

Explore sector

Manufacturing

Explore sector

Marine and Offshore

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Power and Utilities

Explore sector

Rail

Explore sector

Renewables

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A complete guide to Metal Failure Modes and Analysis

Testing

How combining NDT Methods ensures comprehensive asset protection

Testing

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What Are the Different Methods of NDT Testing?

Testing

How to Choose the Right NDT Method: A Comprehensive Guide

Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team