Structural Investigations, Testing and NDT

Concrete Testing

Assess the composition of infrastructure assets with Concrete Testing solutions

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is Concrete Testing?

As part of our Structural Investigation and NDT Testing solutions, various methods of Concrete Testing can be applied to an infrastructure asset containing concrete, to help determine the composition of a structure and assess levels of deterioration.

A Concrete Test can be used to identify issues which may impact the structural integrity of concrete such as corrosion, delamination, and spalling. Concrete condition surveys can also be used to investigate what type of concrete a structure is made of, the strength of the structure and examine the condition of reinforcement layers covering rebars.

We can conduct Concrete Testing across various sectors such as:

- Highways: For bridges, buildings, culverts, barriers, and roads.

- Railways: For tunnels, viaducts, bridges, platforms, and railway lines.

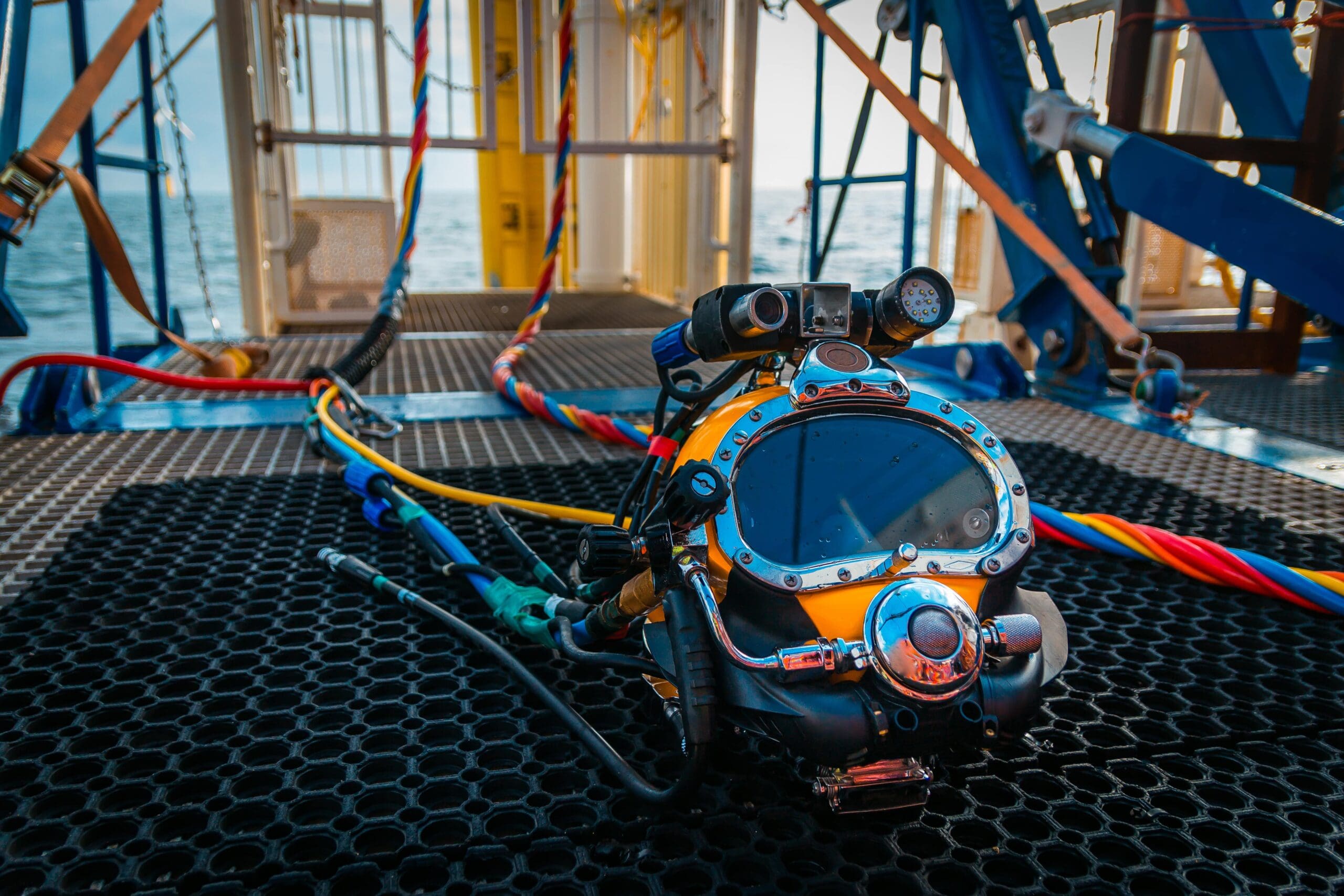

- Marine and Offshore: For elevated platforms, rigs, and various marine structures.

Who we’ve partnered with...

Benefits of Concrete Testing services

Structural integrity

Surveys provide valuable insights into the strength, durability, and composition of concrete structures, to ensure whether a structure is safe and highlight where maintenance is required.

Safety compliance

Our expert teams ensure that every Concrete Survey is conducted in accordance with the highest safety standards and in compliance with regulations.

Access solutions

We’re proud to have an extensive team of engineers which can utilise a variety of specialist access methods, to ensure that all infrastructure assets can be reached regardless of location or environment.

Diverse application

With our turnkey approach, we can incorporate Concrete Testing solutions across several different services and cover all aspects from inspection to analysis.

Let's talk about Concrete Testing

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Intrusive Concrete Testing

During the investigation and examination of an infrastructure asset, there are intrusive and non-intrusive methods of Concrete Testing that may be applied to determine the strength, composition, or deterioration level of concrete.

Intrusive methods of Concrete Testing involve more rigorous forms testing such as extractions, drilling and chemical application.

| Type of Test | Application |

|---|---|

| Core Drilling and Testing | This is used to test the strength of concrete within a structure by extracting and examining core concrete samples, to provide visual evidence that can display aggregate size, composition, and thickness. |

| Chloride Content Testing | Involves drilling concrete to extract dust for analysis. The concrete dust samples are tested for chloride ions and sulphate levels, this can be tested chemically or by using ion-specific electrodes. |

| Carbonation Concrete Testing | This method uses a phenolphthalein indicator to spray across exposed concrete, this helps to determine the extent of carbon dioxide infiltration and assess the carbonation depth in concrete. |

| High Alumina Cement (HAC) Content Testing | Involves extracting a sample of concrete to examine and inspect for the presence of HAC concrete, which can weaken concrete over time. |

| Half Cell Potential Testing | This is used to evaluate the likelihood of corrosion, by spraying a mapped surface of concrete with a wetting agent and using a half-cell electrode to measure voltage. |

| Resistivity Testing | This method is used to assess the resistance of an electrical current or the passage of chloride within a concrete structure, using a resistivity device probe. This test should only be conducted after a half cell test and cover meter survey to avoid cell reading discrepancies. Concrete resistivity tests are provided by XEIAD Ltd, part of BES Group. |

Non-intrusive Concrete Testing

This type of testing is also referred to as non-destructive Concrete Testing, as it allows concrete to be assessed without permanent modification or damage.

| Type of Test | Application |

|---|---|

| Cover Meter Survey | This involves using an electromagnetic device to determine the depth of cover to reinforcement steel within concrete. |

| Rebound Hammer Testing | This is a non-intrusive method which uses a rebound hammer to test delamination and strength of concrete. |

| Rebar Scanning | This method is used to detect and map steel reinforcing bars which are used to strengthen concrete structures. It’s conducted by using scanning equipment such as Ferroscan, to locate and identify rebars buried within concrete. |

| Intrusive Rebar Testing | This intrusive alternative involves removing concrete to expose reinforcement bars for inspection and tensile testing. Provided by Inspire Structures, part of BES Group. |

| Pull-off Testing | A metal component is attached to the concrete using adhesive and pulled, this is used to measure the adhesive strength of coatings or the surface strength of substrates |

Our process

Speak to us about the processThere are various techniques of intrusive and non-intrusive Concrete Testing that can be applied to infrastructure assets that contain concrete.

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What’s the difference between chloride ion testing and carbonation testing?

The main difference between chloride concrete testing and carbonation concrete Testing is the type of substance which is being tested. A carbonation test of concrete uses a phenolphthalein indicator, which is sprayed onto the concrete structure. This intrusive investigation will indicate the depth of carbonation. Whereas Concrete Chloride Testing involves testing for the level of chloride content, this is obtained a taking a dust sample from the concrete structure by incremental drilling. The dust sample is submitted for laboratory analysis. The methodology can vary between each test, but this is dependent on the structure and environment.

Why is it important to test Concrete structures?

Concrete Testing is vital to understand the safety and condition of an infrastructure asset. Concrete can be damaged by various factors such as: Corrosion Fatigue Overloading Environment

This type of damage may cause issues such as:

- Cracks Delamination

- Scaling

- Spalling

- Abrasions

Concrete Testing can help identify the extent of the damage so that maintenance and repairs can be conducted prior to failure of the asset.

What's the difference between an intrusive investigation and a non-intrusive investigation?

An intrusive investigation directly impacts the area that is tested. For example, Carbonation Measurement requires drilling into the concrete structure to obtain a dust sample for laboratory tests to be conducted. Intrusive methods can be used alongside non-intrusive techniques for comprehensive testing. Non-intrusive investigations inspect and gather information without disturbing the structural asset.

For example, a rebar scanner can observe the depth and size of the reinforcement bars within a concrete asset, without directly impacting the concrete. Non-intrusive methods are considered quicker and more cost-effective, but they cannot offer the same level of in-depth sampling and analysis that intrusive methods provide.

What are the most common causes of deterioration to Concrete structures?

The most common causes of deterioration in concrete are: Overloading and impacts: When concrete structures are subjected to significant loads, they may develop micro-cracks and larger cracks. Such overloading can result from operational changes in the concrete structure that lack appropriate structural upgrades and unusual events like earthquakes. Chemical attack: This can occur when sulfates (of sodium, potassium, calcium, or magnesium) that are dissolved in soil, seawater, or groundwater, permeate the concrete. These compounds react with the hydrated compounds and expand, causing concrete damage. Fire damage: When concrete structures are exposed to high heat, they lose their compressive strength and elasticity. Reinforcement corrosion: This occurs when the concrete’s pH is reduced to 10 or less. The reduction in the pH allows chloride ions, oxygen, and moisture into the pores and micro-cracks. This leads to the rust volume being greater than steel, which stresses the surrounding concrete, resulting in cracks, delamination and spall. Carbonation: This occurs when carbon dioxide penetrates through the pores and micro-cracks of the concrete. The carbon dioxide reacts with the hydroxides, such as calcium hydroxide, which forms calcium carbonate. The product of the reaction reduces the pH in the concrete structure; this exposes the reinforcement bars to corrosion.

What is Concrete spalling?

Spall is a term used to describe the fragments that fall off or break off a bigger object. Spalling can occur when the concrete structure is exposed to excess moisture, corrosion, and weathering. For example, sometimes small sections of concrete can break off a bridge due to corrosion from excessive wet weather.

What are the two types of Rebar Testing?

Rebar Testing can be an intrusive or non-intrusive method of structural investigation. The intrusive method for rebar testing involves physically exposing the reinforcement bars through drilling or removal of concrete, the asset is then visually inspected or scanned to examine the rebars. The non-intrusive method of rebar scanning involves scanning the surface with scanning equipment, such as a Ferroscan to analyse the distance of the rebar and accurately measure the location and depth of the reinforcement bars.

What is High Alumina Cement (HAC) concrete?

High Alumina Cement (HAC) is a type of cement that is composed primarily of calcium aluminates. A high amount of alumina cement can cause issues with the concrete structures’ strength and leave it susceptible to chemical damage.

How often should you test Concrete structures?

Concrete structures should be inspected regularly to maintain safety standards. The recommendation is to have a routine inspection every five years. Regular concrete testing will ensure the structural integrity of your asset.

Is it a statutory requirement to test Concrete structures?

Duty holders will typically have a legal obligation to maintain and carry out concrete testing on structures if it has been made part of a contractual agreement. For example, railway companies will often have a contractual obligation to ensure structures are compliant and safe to use.

Can you test Concrete in difficult locations?

Depending on where the structure is situated, there may be several external factors which impact access such as weather, heights, water, and remote locations.

We’re proud to provide a variety of Specialist Access Support techniques such as Confined Space Access, Drone Inspections, Rope Access, Suspended Working Platforms and Marine Safety systems to help investigate concrete structures and identify hidden critical elements.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team