Asset Reliability

Gas Leak Detection and Repair Services (LDAR)

Identify and manage gas emissions effectively with BES Group’s advanced Leak Detection and Repair (LDAR) services in partnership with OSS Enviro.

Explore our process

Interested? Let’s talk.

Send us an enquiry

Who we've partnered with...

What is Gas Leak Detection and Repair (LDAR)?

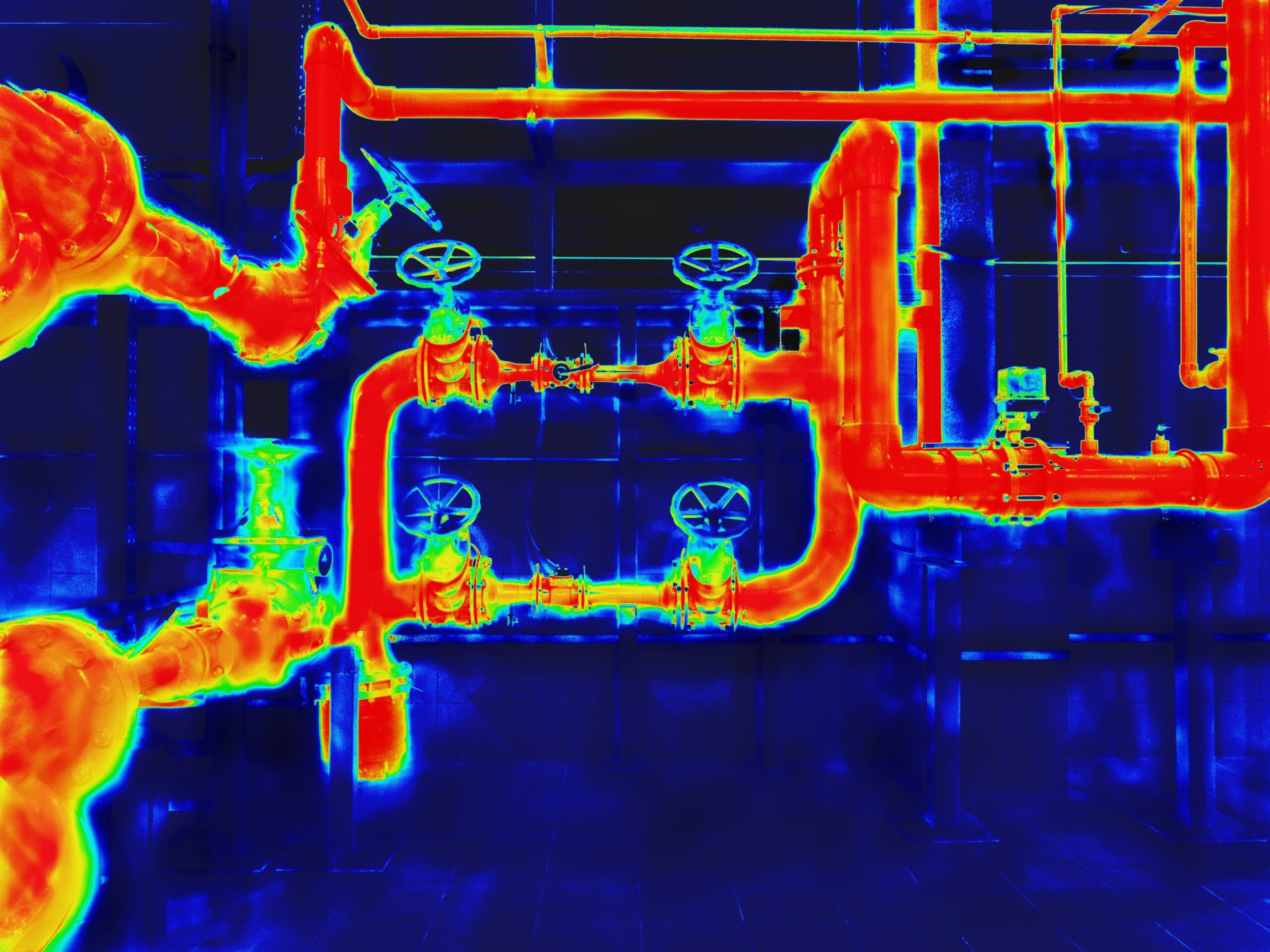

Our LDAR solutions accurately detect and quantify various gas leaks utilising cutting-edge optical gas imaging (OGI) cameras. We prioritise methane detection to support emissions targets set by the Oil and Gas Methane Partnership 2.0 (OGMP 2.0) and the Methane Action and Monitoring Initiative (MAMII).

Methane and gas leak quantification

Leak Detection and Repair (LDAR) is crucial for finding and quantifying gas leaks to reduce environmental impact and enhance regulatory compliance. LDAR monitoring detection is suitable for any sector where managing emissions is essential and may use gas as a fuel source, including natural and man-made gases. So, whether you’re a manufacturing plant, a power station, or a large-scale oil and gas company, we can tailor our services to meet your needs. We’ll work with you to create an LDAR programme based on your industry requirements, considering everything from your specific operations to regulatory obligations.

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

Gas Leak Detection and Repair (LDAR) process

Speak to us about the processWe will help you identify the source of gas leaks and provide tailored recommendations for effective solutions.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Gas Leak Detection and Repair Services (LDAR) at BES Group

Explore LDAR Services- Who can benefit from LDAR services?

- Why is methane gas leak protection important?

- OGMP 2.0 (Oil and Gas Methane Partnership 2.0)

- MAMII (Methane Action and Monitoring Initiative)

- Key benefits of LDAR

Our LDAR services cover methane detection—a major contributor to greenhouse gas emissions.

Our expertise in this area means you can identify methane leaks easily and take immediate action to support your sustainability goals. With BES Group, you can effectively manage gas emissions and detect costly leaks to reduce risks to your operations. Our LDAR services help you improve operational efficiency and contribute to a cleaner, more sustainable future.

LDAR can be applied to key industries such as:

- Manufacturing

- Production

- Power stations

- Refineries

- Oil and Gas

- Marine and offshore

Methane is a potent greenhouse gas therefore addressing methane emissions is essential for meeting environmental goals.

Investing in methane detection isn’t just about emissions targets—it’s also a proactive move toward sustainability and operational efficiency. Prioritising methane leak detection can drive your commitment to environmental sustainability and enhance your business’ resilience.

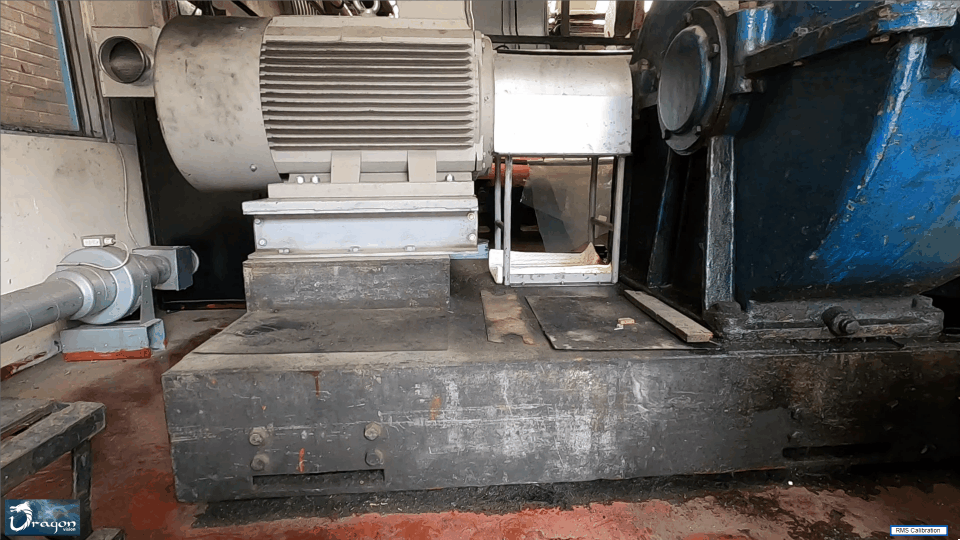

Gas leaks can occur in various locations, including:

- Machine bases and pipework

- Storage vessels

- Engines

- Supply lines

- Kilns

The OGMP 2.0 initiative brings together oil and gas companies that want to reduce methane emissions.

It involves sharing best practices in leak detection and repair. Participating businesses can enhance their reputation and align with global climate goals, making advanced methane detection a priority.

MAMII promotes improved methane monitoring and reporting standards across industries.

This initiative promotes innovative technologies for accurately measuring methane, enabling businesses to understand and reduce their methane emissions.

Reduce carbon footprint

Minimise your carbon footprint with effective gas leak detection services, helping to lower greenhouse gas emissions and support global climate goals.

Improve health and safety

Reduce risks to health and safety by identifying and managing methane leak detection, reducing the risk of gas exposure and potential hazards in indoor facilities.

Drive sustainability initiatives

Support sustainability goals by implementing LDAR to demonstrate your commitment to environmental initiatives and reducing your emissions impact.

-

Who can benefit from LDAR services?

Our LDAR services cover methane detection—a major contributor to greenhouse gas emissions.

Our expertise in this area means you can identify methane leaks easily and take immediate action to support your sustainability goals. With BES Group, you can effectively manage gas emissions and detect costly leaks to reduce risks to your operations. Our LDAR services help you improve operational efficiency and contribute to a cleaner, more sustainable future.

LDAR can be applied to key industries such as:

- Manufacturing

- Production

- Power stations

- Refineries

- Oil and Gas

- Marine and offshore

-

Why is methane gas leak protection important?

Methane is a potent greenhouse gas therefore addressing methane emissions is essential for meeting environmental goals.

Investing in methane detection isn’t just about emissions targets—it’s also a proactive move toward sustainability and operational efficiency. Prioritising methane leak detection can drive your commitment to environmental sustainability and enhance your business’ resilience.

Gas leaks can occur in various locations, including:

- Machine bases and pipework

- Storage vessels

- Engines

- Supply lines

- Kilns

-

OGMP 2.0 (Oil and Gas Methane Partnership 2.0)

The OGMP 2.0 initiative brings together oil and gas companies that want to reduce methane emissions.

It involves sharing best practices in leak detection and repair. Participating businesses can enhance their reputation and align with global climate goals, making advanced methane detection a priority.

-

MAMII (Methane Action and Monitoring Initiative)

MAMII promotes improved methane monitoring and reporting standards across industries.

This initiative promotes innovative technologies for accurately measuring methane, enabling businesses to understand and reduce their methane emissions.

-

Key benefits of LDAR

Reduce carbon footprint

Minimise your carbon footprint with effective gas leak detection services, helping to lower greenhouse gas emissions and support global climate goals.

Improve health and safety

Reduce risks to health and safety by identifying and managing methane leak detection, reducing the risk of gas exposure and potential hazards in indoor facilities.

Drive sustainability initiatives

Support sustainability goals by implementing LDAR to demonstrate your commitment to environmental initiatives and reducing your emissions impact.

LDAR FAQs

What does the BES Group and OSS Enviro partnership involve?

At BES Group we’re proud to be official partners with OSS Enviro for LDAR services.

OSS Enviro are well renowned and respected, with over 40 years of accumulated industry knowledge within Optical Gas Imaging (OGI) technology and Gas Leak Detection and Repair (LDAR).

This leading partnership allows us to share vital insights, expertise, and support which enables us to deliver an exceptional experience to our client portfolios, across multiple key sectors including Oil and Gas, Petrochemical and Energy Generation.

How is liquified natural gas produced?

Liquefied natural gas (LNG) is produced through a process called liquefaction, which involves cooling natural gas to approximately -162°C.

This temperature reduction transforms the gas into a liquid, reducing its volume approximately 600 times, making it easier to transport and store.

The production process typically involves removing impurities, such as water and carbon dioxide, before cooling the gas. Once liquefied, LNG can be transported in specialised cryogenic tankers for use.

What are volatile organic compounds?

Volatile organic compounds (VOCs) are organic chemicals containing carbon and with a high vapour pressure at room temperature. This allows them to evaporate easily into the air.

VOCs include a variety of substances found in everyday products such as:

- Benzene: Often found in gas and industrial emissions.

- Formaldehyde: Used in building materials and household products.

- Toluene: Commonly used as a solvent in paints and coatings.

VOCs can have adverse health effects and contribute to air pollution, so regulating and monitoring their use is crucial.

How are volatile organic compounds produced?

Volatile organic compounds (VOCs) are produced from both natural and human-made sources, including:

- Industrial processes: Emitted during the manufacturing of paints, solvents, and plastics (e.g., toluene, xylene).

- Vehicle emissions: Produced by combustion engines in cars and trucks, contributing to air pollution.

- Household products: Found in cleaners, air fresheners, and personal care items, often evaporating into indoor air.

- Natural sources: Emitted by plants, with terpenes contributing to natural scents.

VOCs pose significant environmental concerns. They can contribute to ground-level ozone formation which worsens air quality and creates health risks, including respiratory issues. They can also act as greenhouse gases—known for impacting climate change.

What does LDAR stand for?

LDAR stands for Leak Detection and Repair. It was developed in the 1970s to address environmental and health concerns relating to industrial emissions.

It’s a systematic approach to identifying and addressing gas leaks, particularly focusing on volatile organic compounds (VOCs) and methane emissions.

LDAR is essential for environmental protection, especially in industries such as oil and gas. If you’re looking for expert LDAR services, contact BES Group via our online form.

What is an OGI camera?

An Optical Gas Imaging (OGI) camera is a thermal imaging device used to detect and visualise gas leaks, including methane and VOCs. It’s used for the following:

- Gas leak detection: OGI gas imaging cameras provide real-time visuals of gas emissions, allowing for quick identification of leaks.

- Safety enhancement: Optical gas imaging helps mitigate risks of hazardous gas exposure, improving workplace safety.

Where do gas leaks commonly occur?

Gas leaks can occur in various settings, leading to safety hazards and operational inefficiencies. Common examples include:

- Manufacturing facilities: Gas leaks often happen where natural gas or fuels are used in production processes, machinery, and heating systems.

- Refineries and chemical plants: These facilities are prone to leaks in storage tanks, piping, and valves due to handling volatile substances.

- Power plants: Gas leaks can occur in combustion engines and boilers, particularly in natural gas-fired plants.

- Oil and gas operations: Exploration and extraction sites frequently experience leaks from equipment, pipelines, and storage facilities.

- Commercial kitchens: Gas leaks can occur from stoves, ovens, and appliances where natural gas is used for cooking.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

A Complete Guide to Asset Condition Monitoring

Asset Reliability

What are the four types of maintenance strategies

Asset Reliability

BES Group awarded ADC of the year

Asset Reliability BES Group News

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

What are the types of oil analysis qualification?

Asset Reliability

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team