Statutory Inspections

Pressure System Inspection Service

If you own or operate a Pressure System, it is important to have it inspected regularly to ensure that it’s compliant with the Pressure Systems Safety Regulations 2000 (PSSR).

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is a PSSR Inspection?

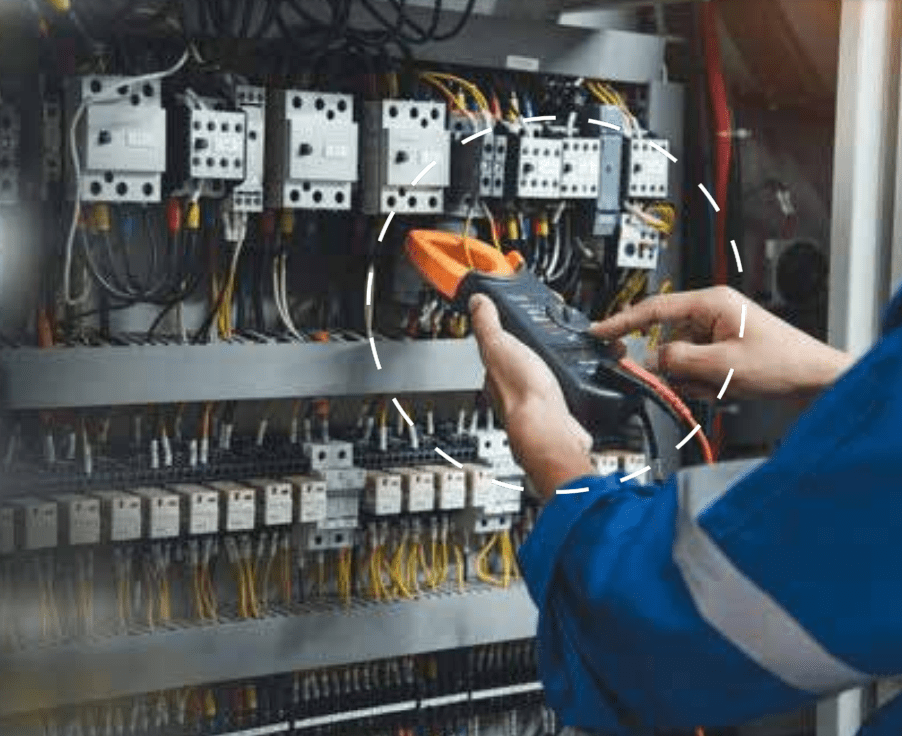

A PSSR Inspection, or “Pressure System Safety Regulations”, is an essential safety check. It’s performed before starting any new or changed process in a factory or plant. During a PSSR Inspection, we check the safety, health, and environment of your pressure systems. This includes the designs, safety systems, procedures, training, and documents.

The main aim of a Pressure System Inspection is to find and fix any potential dangers or risks that could harm people, equipment, or the environment. These checks can prevent accidents and costly fines, helping you to mitigate risk more effectively across your assets. Plus, it’ll ensure you follow regulations, helping to keep your colleagues safer at work. Not only are these regulations a legal obligation, but they also ensure your pressure systems are running safely and efficiently.

Who we’ve partnered with...

Key benefits of Pressure System Inspections

Increased safety

Pressure System Inspections can help to identify and correct potential hazards, reducing the risk of accidents.

Reduced downtime

By identifying and correcting potential problems before they cause a failure, PSSR Inspections can help to reduce downtime.

Increased productivity

By ensuring that pressure systems are operating safely and efficiently, PSSR Inspections can help to increase productivity.

Reduced liability

By complying with PSSR, businesses can reduce their liability in the event of an accident.

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you to conduct a PSSR inspection

For most Pressure Systems, an ‘out of service’ and ‘in service’ examination is usually required. Our team of experts will carry out your end-to-end Pressure Vessel Inspection requirements and we’ll do it around the requirements of your business, too. Safety is our number one focus, and we’ll do everything we need to complete your inspections both safely and efficiently.

BES Group can help you to stay safe and compliant with our PSSR Examinations.

We abide by all safety rules to the highest possible standards, ensuring inspections are carried out frequently to maintain compliance of your assets. Upon completion of our inspection, we will provide you with a comprehensive report on our findings, so you’re equipped with the right information on where you’ll need to take corrective action.

Experienced PSSR Engineers

We have a team of experienced, highly qualified and accredited engineers with expertise spanning a range of sectors, so you can rest assured that your inspections are carried out to the highest standards.

Expert inspections in line with PSSR regulation

The rules for PSSR Inspections state that pressure systems must be checked by a Written Scheme of Examination. The Written Scheme of Examination outlines how often and what needs to be checked for each pressure system. These checks must be done by a “competent person”. A competent person is defined as someone who has the necessary knowledge, skills, and experience to carry out the inspections safely and effectively. A pressure system includes any ‘system’ made up of:

Pipelines that contain relevant fluids.

These fluids include steam, gases under pressure, or those that are artificially kept under pressure and become gases when they’re released.

One or more rigid pressure vessels with pipework and protective devices.

Pipework with a transportable pressure vessel.

Our Pressure System Inspection Process

We carry out your end-to-end Pressure Vessel Inspection requirements and we’ll do it around the requirements of your business, too. Our PSSR inspection process includes:

Let’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

An end-to-end solution

Servicing the full life cycle, from concept through to decommission.

Accredited assurance

Confidence assured with all relevant certifications and accreditations.

Frequently asked questions

What are the requirements for PSSR Inspections?

The requirements for PSSR Inspections vary depending on the type and size of the pressure system. However, all pressure systems must be inspected in accordance with a Written Scheme of Examination (WSE). The WSE should be drawn up by a competent person and should identify the frequency and scope of the inspections.

How often should pressure systems be inspected?

The frequency of inspections depends on the type and size of the Pressure System. However, most pressure systems should be inspected at least every 12 months

Who can carry out PSSR inspections?

Only competent persons can carry out PSSR Inspections. A competent person is someone who has the necessary knowledge, skills, and experience to carry out the inspections safely and effectively.

What are the consequences of not complying with PSSR?

The consequences of not complying with PSSR can be serious. If a pressure system fails, it could cause serious injury or death. In addition, businesses that fail to comply with PSSR could be prosecuted by the Health and Safety Executive (HSE) or be fined under HSE’s Fee For Intervention charging scheme.

What is a Written Scheme of Examination?

According to the HSE, a written scheme of examination is a document that contains all the relevant information about plant items or equipment that:

- Form a pressure system

- Operate under pressure

- Or contain a ‘relevant fluid’.

Is a coffee machine included in a PSSR Inspection?

Industrial coffee machines are considered pressure systems and are subject to PSSR Inspections. PSSR applies to any equipment that contains liquids at any pressure such as boilers, pressure vessels, compressed air systems and even coffee machines used in industrial settings.

What’s the difference between an installed system and a mobile system?

An installed system refers to equipment permanently fixed or installed in a specific location, such as boilers in a factory. On the other hand, a mobile system is equipment designed to be movable, such as portable pressure washers or mobile air compressors.

What is a competent person in a PSSR Inspection?

A competent person, as defined by the Pressure Systems Safety Regulations (PSSR), is someone who possesses the necessary skills, knowledge, and experience to carry out inspections and maintenance on pressure systems safely and effectively. They should be qualified and impartial.

What are the exceptions to PSSR?

Most pressure systems in factories need PSSR, but there are exceptions. These might include systems used at home, certain heating or cooling systems, and equipment regulated differently, like transportable pressure gear. Check the regulations and ask an expert to be sure if there’s an exception for your situation.

What is the importance of a PSSR Inspection?

Without a PSSR inspection, there’s a greater risk of your pressure systems causing harmful accidents, stress, and even a costly penalty. Plus, businesses that fail to comply with PSSR could be prosecuted by the Health and Safety Executive (HSE) or be fined under HSE’s Fee for Intervention charging scheme.

What does pressure systems equipment include?

Pressure systems can be found in a wide range of machinery. Typically, a pressure system is considered any system that is made up of one or more rigid vessels that contains steam at any pressure. Some examples of pressure systems include:

- Boilers: Usually those operating at more than 100c, although it is recommended that all boilers are inspected.

- Steam heating systems: This encompasses gas, oil and electric burners used to heat compounds to boiling point.

- Air conditioning systems and refrigeration plants: With combined compressor motors exceeding 25kW.

These machines operate using steam, air, or coolants, so it’s important to check them closely to ensure they’re safe and compliant.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Consumer Products

Explore sector

Finance

Explore sector

Highways

Explore sector

Hospitality and Leisure

Explore sector

Transport, Logistics and Distribution Centres

Explore sector

Renewables

Explore sector

Rail

Explore sector

Power and Utilities

Explore sector

Petrochemicals, Oil and Gas

Explore sector

Marine and Offshore

Explore sector

Manufacturing

Explore sector

Aerospace and Defence

Explore sector

Healthcare

Explore sector

Agriculture

Explore sector

Retail

Explore sector

Insurance

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

BES Group expands into Europe with ECH Groep acquisition

Acquisitions BES Group News Inspection

Ensure Your Assets Are Winter-Ready with Pre-Winter and Post-Winter Storage Tank Inspections

Inspection

School Shutdowns: A Comprehensive Guide on Electrical Equipment Maintenance

Electrical Inspection

Storage Tank Inspections: Your Commonly Asked Questions

Inspection

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team