Statutory Inspections

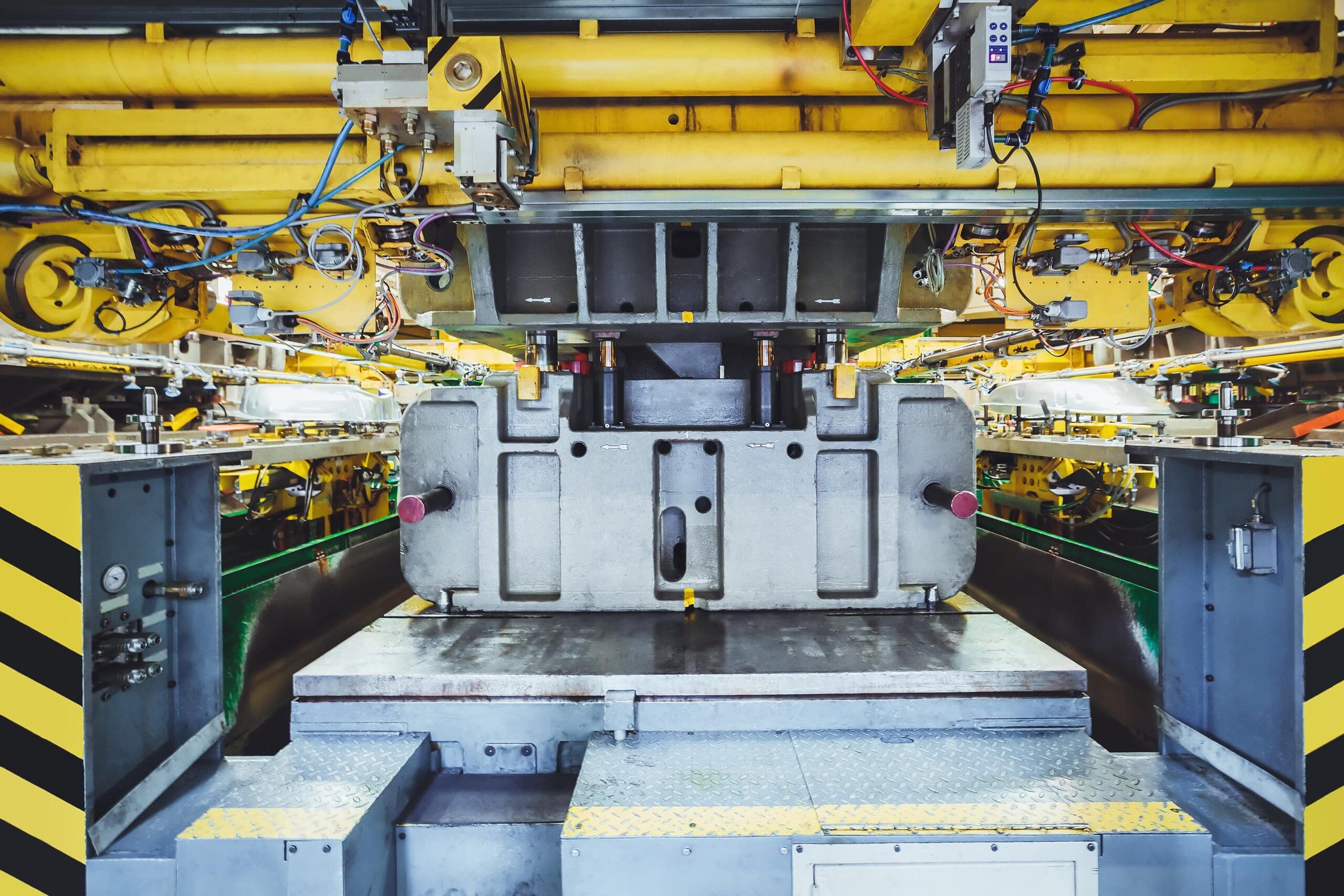

Power Press Inspection Services

Ensuring the safety and compliance of your Power Presses as defined under the Provision and Use of Work Equipment Regulations 1998 (PUWER).

Explore how we work

Interested? Let’s talk.

Send us an enquiry

What is a Power Press Inspection?

Accidents involving power presses are typically caused by ‘trapping between the tools,’ resulting in amputations, life changing injuries, and death. However, these accidents are most often caused by poor maintenance or incorrect setting of the press, its safeguards, and the control system by underqualified individuals.

Regulation 32 of PUWER – The Safe Use of Power Presses, sets out the requirements for the inspection of power press machines, including detailing the required frequency of inspections. It also requires that an independent and qualified person carries these inspections out. And that’s where we come in; at BES Group, we’re proud to be both independent and competent, with decades of experience in inspecting critical machinery, including power presses.

Who we’ve partnered with...

Key benefits

Reduced risk of accidents and injuries

Power presses are powerful machines that can cause serious injuries if they are not properly maintained and inspected. By conducting regular inspections, you can help to identify and correct any potential hazards before they cause an accident.

Regulatory compliance

By conducting regular inspections and having a thorough power press risk assessment plan in place, you can help to ensure that your business is compliant with all the relevant regulations.

Increased productivity

When power presses are properly maintained and inspected, they are less likely to break down. This can lead to increased productivity as employees are not having to spend time waiting for the machine to be repaired.

Reduced costs

When accidents and injuries are prevented, the costs associated with these incidents are also prevented. This includes the cost of medical treatment, lost productivity, and legal fees.

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we'll work with you

We’re proud to say that our team of Engineer Surveyors are accredited, experienced, and qualified to the highest industry standards.

Together, we’ll ensure that your critical Power Press machinery is in full working order with our expert Power Press Inspection Service, and, most importantly, safe for use while causing minimal disruption to your daily operations.

Our comprehensive Power Press Inspection Services provide a systematic approach to identifying and addressing potential hazards, ensuring your equipment operates safely and compliantly.

Our process

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What are the hazards associated with Power Presses?

Power Presses are machines that use a significant amount of force to shape or deform materials. They can be very dangerous if not used properly, and there are several hazards associated with using them.

Some of the most common hazards associated with Power Presses include:

- Crush injuries. This is the most common type of injury associated with power presses, and can happen when a worker’s fingers, hands, or arms are caught between the moving parts of the press.

- Amputations. Crush injuries can also lead to amputations, a serious and often life-changing injury.

- Cuts and lacerations. The sharp edges of the materials being worked on can cause injuries that can be minor or severe, depending on the depth and location of the cut.

- Eye injuries. Flying debris or sparks from the press can cause eye injuries, such as corneal abrasions or even blindness.

- Noise-induced hearing loss. Power presses can be very noisy, and prolonged exposure to noise can lead to hearing loss.

- Electrical shock. Power presses can be electrically powered, and there is a risk of electrical shock if the equipment is not properly maintained.

This is why it’s so important that you have an in-depth power press risk assessment plan in place, and that you’re working with a competent and independent organisation, like the BES Group, to maintain power press safety at your site.

What should be included in a Power Press Inspection checklist?

A Power Press inspection checklist should include the following items:

- Visual inspection. This will include checking for any damage to the press, such as cracks, dents, or missing parts.

- Safety guard inspection. Safety guards should be in good condition and should be properly installed.

- Electrical component checks. The electrical components should be in good condition and should be properly wired.

- Hydraulic system checks. The hydraulic system should be in good condition and should not leak.

- Operating controls checks. The operating controls should be in good working order and should not be damaged.

- Emergency stop button test. The emergency stop button should be in good working order and should be easily accessible.

- Signage inspection. The signage should be clear and easy to understand.

Most importantly, an inspection of a power press should only be carried out by qualified individuals with the right experience and expertise, like the BES Group.

How often should Power Press Inspections be carried out?

In the UK, the Provision and Use of Work Equipment Regulations (PUWER) states that power presses with certain guards must be inspected every 6 months. Power Presses with fixed guards, or enclosed tooling, should be examined every 12 months, by a competent person.

During this process, existing power press control measures should be examined to ensure they’re still effective.

How can I ensure that a Power Press is properly maintained?

To find out how to ensure complete power press safety with proper maintenance speak to us. We’re here to answer your questions, no matter what.

Sectors we service

Dive into the diverse landscapes where BES Group sparks innovation and drives impact.

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

BES Group expands into Europe with ECH Groep acquisition

Acquisitions BES Group News Inspection

Ensure Your Assets Are Winter-Ready with Pre-Winter and Post-Winter Storage Tank Inspections

Inspection

School Shutdowns: A Comprehensive Guide on Electrical Equipment Maintenance

Electrical Inspection

Storage Tank Inspections: Your Commonly Asked Questions

Inspection

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

Other similar services...

Looking for something else? Explore similar services...

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team