Statutory Inspection

Local Exhaust Ventilation Testing

Ensure the health and safety of your staff with regular Local Exhaust Ventilation (LEV) Testing. We have a dedicated team of experts ready to carry out LEV examinations to ensure your systems meet industry standards and HSE guidelines.

Explore our process

Interested? Let’s talk.

Send us an enquiry

What is LEV Testing?

Local Exhaust Ventilation (LEV) is equipment that controls, captures or contains pollutants that are released at ‘or close to’ the point of the emission source. The LEV system will then convey the pollutant where it can be safely collected or released.

The Thorough Examination and Testing (TexT) of your Local Exhaust Ventilation system is undertaken to ensure that the system is operating as originally intended and continues to comply with the requirements of statutory regulations and industry guidelines.

A typical LEV Inspection will cover a check of your documentation, a visual inspection of the system, a detailed examination of all accessible components, airflows and alarm status checks.

LEV Testing is a legal requirement under the COSHH Regulations.

Who we’ve partnered with...

Key Benefits of Local Exhaust Ventilation Testing

Compliance

Ensure your LEV system is compliant with current HSE regulations and guidance by entrusting your TexT to BES Group.

Safety

The health and safety of you and your staff is paramount, so help avoid any accidents or long-term side effects with our LEV Servicing.

Local engineers

We have over 40 BOHS P601 accredited LEV Surveyors nationwide across the UK, employed directly by us. Our dedicated experts are on hand to support you through the entire process.

Let's talk

Send one of the team a message

Not seeing what you expected?

Try using our search

Explore what our clients say

How we work

We have a national team of experts with vast experience across a number of sectors who can carry out the necessary checks and tests to ensure all your equipment is functional, safe and in line with COSHH Regulations. We can carry out inspections on any system whether the harmful substance is dust, fumes, vapour or mist.

Why is an LEV Inspection important?

There are many types of materials and substances used or created in the workplace that could harm you or your staff. The risks associated with exposure to hazardous substances can vary depending on the substance, the level of exposure and the individual.

From dust, fumes and gases that you breathe in, to liquids, gels, or powders that you handle, potentially harmful substances are everywhere, so keeping your LEV Inspections up to date can help to minimise the risk of serious long-term effects from exposure to these substances.

Common applications of LEV

There are many types of materials and substances used or created at work that could harm you and your employees’ health. Local Exhaust Ventilation systems are used across a wide variety of industries and sectors to protect both your workforce and the public. If you work with substances such as respirable crystalline silica, dusty ingredients, isocyanate paints, oil mists associated with machining processes, lead or dichloromethane, you should arrange your LEV Inspection today.

LEV System Testing also includes:

Welding fume ventilation

A common practice in many industries which requires fume extraction.

Woodwork dust ventilation

Woodwork dust is carcinogenic making correct ventilation imperative.

Spray booth fume ventilation

Ensure your spray booth LEV System is meeting COSHH Regulations.

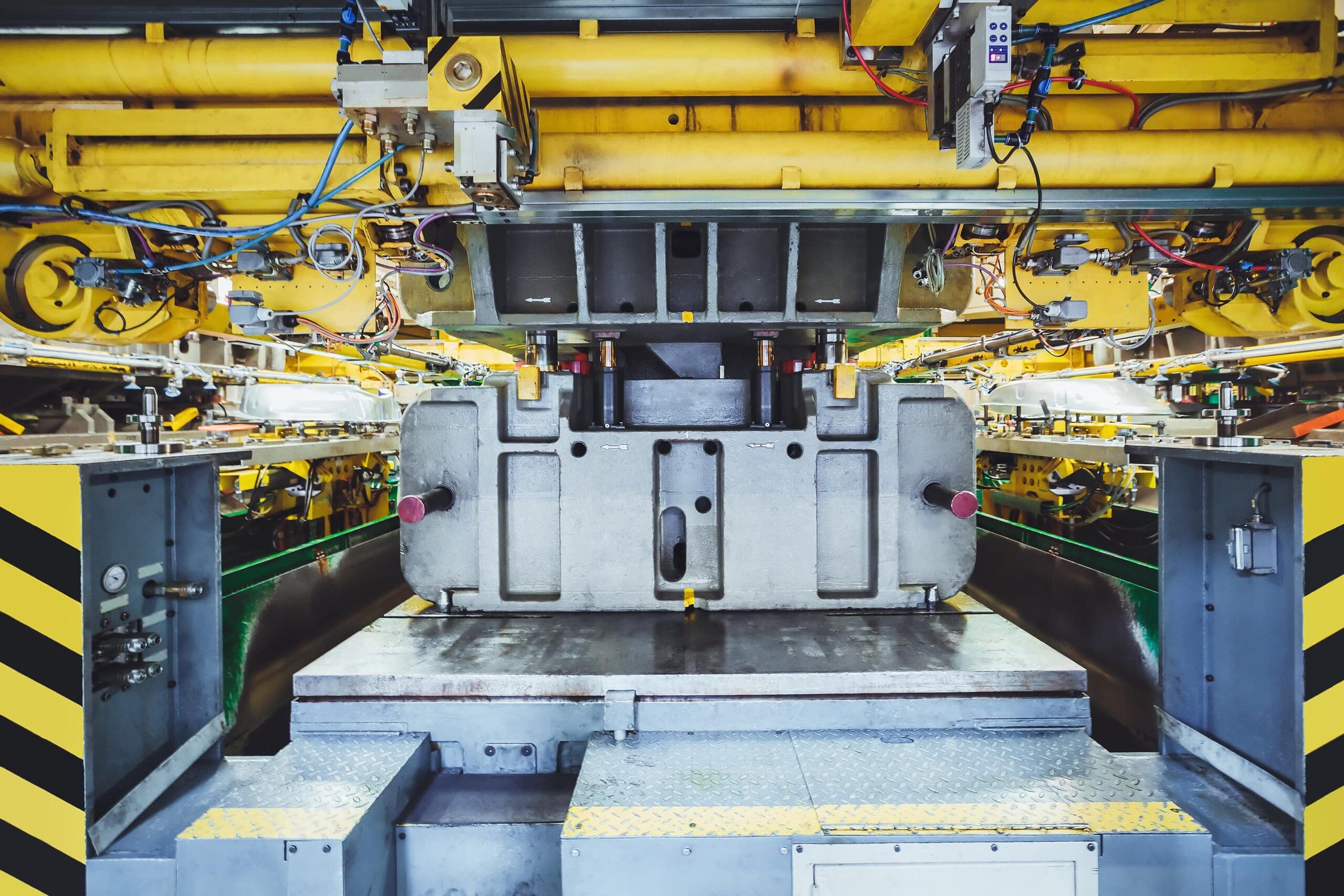

CNC machinery ventilation

If using oil to cool, your CNC machine will require an LEV system.

What happens during a typical LEV Inspection?

Speak to us about the processLet’s talk. Ask us anything.

Send one of the team a message

Why choose BES Group?

800+ expert engineers

Our team of skilled engineers possesses a wealth of expertise.

A legacy of 160+ years of experience

We’re always evolving our approach to future proof our services.

35,000 satisfied customers

A strong reputation for providing exceptional service.

Frequently asked questions

What is a Local Exhaust Ventilation System?

A Local Exhaust Ventilation system is equipment that controls, captures or contains pollutants released at the point of the emission source The LEV system will then transfer any pollutants, where they can be safely collected or released.

What is an LEV Test?

LEV Testing Services are undertaken to ensure that the system is operating as originally intended. This also ensures your LEV system complies with legal requirements, statutory regulations and industry guidelines outlined by the HSE. This test is also sometimes referred to as a COSHH Test.

A typical inspection will cover the following;

- Examining the entire system to check mechanical function and cleanliness

- A detailed look at all parts of the system, including the fans, hoods and filters

- Airflow measurements

- Alarm checks

On completion of an inspection, you will receive a comprehensive report outlining the measurements, observations and findings, including any faults or issues regarding your system.

Why is an LEV Inspection important?

There are many types of materials and substances used or created in the workplace that could harm you or your staff. The risks associated with exposure to hazardous substances can vary depending on the substance, the level of exposure and the individual.

From dust, fumes and gases that you breathe in, to liquids, gels, or powders that you handle, potentially harmful substances are everywhere, so keeping your LEV Inspections up to date can help to minimise the risk of serious long-term side effects from exposure to these substances.

Does my workplace need an LEV Inspection?

There are lots of workplaces and sectors that need to comply with COSHH Regulations such as factories, quarries, mines, woodworking and plastics factories, but there are others that you may not be aware fall under these regulations, including:

What happens is my system fails the inspection?

If your system fails the inspection, you should ensure the problem is resolved quickly and efficiently to ensure your continued compliance with the COSHH Regulations. . In most cases, any faults can be easily repaired or faulty components replaced, and in very rare cases, the entire fume extraction system may need replacing. Our LEV Engineer Surveyor will discuss findings with you.

To help avoid the failure of your LEV System, we recommend that daily and weekly checks are implemented in addition to periodic LEV Servicing.

How often do I need an inspection?

Normally an inspection is needed every 14 months, however some systems and trades may require testing as often as every month or six months. Our team will be able to advise how often your system will require an inspection.

For example:

- Metal/shot blasting of raw castings require monthly inspections

- Non-ferrous metalworking requires an inspection every six months

Most other systems would require an examination every 14 months, but please speak to our team to confirm how often your LEV will need inspecting.

What is COSHH Regulation?

The Control of Substances Hazardous to Health Regulation was put in place to help prevent or reduce the risks associated with handling, storing or transporting potentially harmful substances. COSHH states that ‘every employer shall ensure that the exposure of their employers to substances hazardous to health shall be prevented, or where it is not reasonably practicable, adequately controlled.’ To control the hazard, a Local Exhaust Ventilation system should be implemented.

At BES Group, your safety is our priority with our team of specialists who work across the UK mainland and Northern Ireland, keeping local exhaust ventilation systems in full working order and compliant with the COSHH Regulations.

What regulations cover LEV?

The following regulations, as well as COSHH, impose duties to provide and maintain an LEV system:

What are the risks of a faulty LEV System?

- Health issues including respiratory problems, skin problems and cancer.

- Accidents in the workplace including fires, explosions and poisonings.

- Legal liability after the injury or death of a member of staff exposed to harmful substances or unregulated equipment.

What documentation will I need for my LEV Servicing and Testing?

To assist the LEV Inspection, the LEV Surveyor may request the following information:

- COSHH Risk Assessment as required by Regulation 6 to identify the hazardous substances associated with the process and any residuals that may cause a health hazard within the LEV system.

- Identification of any mechanical safety risks associated with either the process or the LEV system.

- The commissioning report and the design data showing the Intended Operating Performance for the LEV System.

- The LEV User Manual.

- The LEV Logbook.

- The previous Thorough Examination and Test Report.

- Records of Air Sampling relevant to the LEV System.

- Procedures identifying how the users of the system interact with the process.

- Confirmation that there have been no changes to the LEV System, layout or process since the last inspection.

Sectors we service

We are able to service any LEV System no matter the industry. Some examples of the sectors we cover include;

Explore sector

Aerospace and Defence

Explore sector

Automotive

Explore sector

Building, Properties and Real Estate

Explore sector

Consumer Products

Explore sector

Finance

Explore sector

Hospitality and Leisure

Explore sector

Transport, Logistics and Distribution Centres

Explore sector

Renewables

Explore sector

Rail

Explore sector

Agriculture

Explore sector

Retail

Explore sector

Insurance

Let’s talk. Ask us anything.

Send one of the team a message

Insights & news

Browse our latest articles

BES Group expands into Europe with ECH Groep acquisition

Acquisitions BES Group News Inspection

Ensure Your Assets Are Winter-Ready with Pre-Winter and Post-Winter Storage Tank Inspections

Inspection

School Shutdowns: A Comprehensive Guide on Electrical Equipment Maintenance

Electrical Inspection

Storage Tank Inspections: Your Commonly Asked Questions

Inspection

Factory Shutdowns: How to Manage Your Maintenance Operations Efficiently

Asset Reliability Electrical Inspection Testing

Let’s get you to the right person, fast.

Thank you, enquiry submitted!

Please check your inbox. We have sent you an email receipt of your enquiry.

We treat every enquiry with the upmost urgency. We’ll aim to get in touch with the relevant BES Group specialist and get back to you as soon as possible*.

Thank you again and have a great day.

* Schedule dependant, this will usually be within a few hours of your enquiry.

Other similar services...

Looking for something else? Explore similar services...

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team