Manufacturing

In the manufacturing sector, where innovation and efficiency are paramount, BES Group is committed to propelling your manufacturing journey to new heights as your trusted advisor.

Our expertise in engineering services extends across the entire spectrum of manufacturing operations, enabling us to identify and address our customers’ unique challenges, and ensure their continued success. With our comprehensive solutions, we foster asset reliability, minimising downtime and ensuring the smooth functioning of your machinery. We adhere to the most stringent safety regulations, ensuring complete regulatory compliance, operational efficiency, and the safety of our customers and their team.

Explore our expert services

From electrical solutions to industry-leading monitoring technology and asset inspections, our team of specialists at BES Group are here to support you with your unique requirements and elevate your operations.

Statutory Inspections

Consultancy

Condition Monitoring

Condition-Based Maintenance

Energy Survey Services

Lubrication Services

Non-Destructive Testing

Electrical Solutions

Lifting Services

Ready to enhance your manufacturing processes?

Contact us today to implement a robust preventative maintenance programme that reduces costs, boosts efficiency, and minimises the risk of unplanned downtime.

Get in touch today! Get in touch today! Get in touch today!Our industry-leading, end-to-end risk management service offering for the manufacturing sector

Inspection

At BES Group, our expertise in inspection services extends across the entire spectrum of manufacturing operations, ensuring the integrity and compliance of your critical assets.

We conduct asset inspections in line with the most prolific industry regulations, including:

- The Lifting Operations and Lifting Equipment Regulations (LOLER): We have decades of experience in assessing lifting equipment, including forklifts, overhead gantry cranes, and cherry pickers, ensuring their structural integrity, operational safety, and compliance with LOLER regulations.

- The Pressure Systems Safety Regulations (PSSR): We thoroughly examine pressure systems, such as boilers, vessels, and piping, verifying their integrity, safety features, and compliance with PSSR regulations.

- The Provision and Use of Workplace Equipment Regulations (PUWER): Along with assets that falls under PUWER, we can also conduct comprehensive PUWER assessments for newly introduced manufacturing equipment, ensuring it meets the required safety standards and poses no risk to you or your team.

We can also inspect racking systems in accordance with both PUWER and LOLER, depending on the type of load they are intended to carry.

Get in touch to find out more!Non-Destructive Testing

BES Group stands as your trusted partner in providing comprehensive non-destructive testing (NDT) services.

Our team of experienced inspectors utilises advanced techniques to assess the integrity of your critical assets, ensuring they meet the highest standards and comply with the most stringent regulations.

Our NDT services encompass a wide range of techniques, tailored to specific manufacturing processes and applications. Just some of the specialist services we can provide include:

- Ultrasonic Testing

- Radiography

- Positive Material Identification

- Q10 Material Sampling and Analysis

- Liquid (Dye) Penetrant Inspection

We can also offer weld inspections to verify the quality of welds in structures, pressure vessels, and other critical components.

As part of our Technical Consultancy offering, we can conduct design reviews for pressure systems and vessels manufacturing processes, as well verifying pressure systems.

Whether you require ultrasonic testing, radiography, or other NDT methods, our team is equipped to handle your specific needs.

Get in touch to find out more!Electrical solutions

Within manufacturing operations, efficiency and safety are paramount.

This is why BES Group, as your trusted advisor, is here to provide our customers with comprehensive electrical services, including:

- TEGG

As one of only four providers in the UK, we can provide our TEGG service to minimise downtime, enhance fault detection, elevate safety, and reduce the risk of fires for our customers. At BES Group, our TEGG service can expertly safeguard your manufacturing facility from costly property damage and accidents, without the need for operational downtime. - Electrical Installation Condition Reports (EICRs)

We can help you to comply with safety regulations and identify potential hazards with our in-depth EICR service offering. We can carry out a thorough assessment of your electrical installation, identifying any defects, damaged components, or outdated equipment, ensuring the continued safety of you and your people. - Emergency Lighting Testing

Our comprehensive emergency lighting service covers design, testing, and repair, supplying you with an end-to-end safety solution that ensures complete compliance, and the confidence that if an emergency happens, your escape routes will be fully illuminated. - Portable Appliance Testing (PAT)

We prevent electrical hazards and protect your workforce with regular PAT inspections, helping to identify any faults or hidden damage to your electrical fires, preventing electrical accidents and safeguarding your workforce.

Monitoring capabilities

As your trusted provider, BES Group are equipped, experienced, and skilled at providing expert monitoring solutions to ensure the smooth operation and integrity of your manufacturing processes, including:

- Structural Monitoring to help safeguard your manufacturing operations and optimise asset performance. We can offer a full suite of structural monitoring solutions, including Fatigue Monitoring, which allows us to directly assess the condition of your equipment, enabling proactive maintenance to prevent premature failures. This helps to minimise downtime, ensuring your production efficiency remains high.

- Silo Weighing and Level Monitoring Systems to help ensure accurate measurement of contents within silos and tanks, optimising filling and preventing overflows, reducing waste and helping to maintain consistency in your manufacturing process.

- Hazardous Area Footswitches, which are load cells that can support customers in complying with ATEX explosive environments regulations and help to maintain safety and compliance standards.

- Floor Strength Monitoring for manufacturing spaces with changing load requirements,, and

- Hanger Monitoring to maintain chassis integrity.

- Roof Monitoring for structural stability, helping to identify potential issues early on, preventing structural failures and ensuring the safety of your facility.

- Container Weighing Systems (CWS) to accurately measure the weight of containers before shipping, ensuring compliance with international regulations and minimising cargo discrepancies, contributing to smooth and efficient shipping operations and minimising delays.

- Bespoke design solutions for certain specifications and unique customer requirements, designed by our team of experts.

Expert asset maintenance

At BES Group, our team of experienced engineers are dedicated to helping you minimise downtime, optimise resource allocation, and achieve peak operational performance, while also reducing your energy consumption with our asset maintenance solutions.

We can support your operations with:

- Vibration Analysis to identify abnormalities in machinery vibration patterns, providing early warning of potential failures and enabling proactive maintenance to minimise downtime.

- Oil Analysis to provide valuable insights into the condition of your machinery lubricants, enabling you to make informed decisions about maintenance and lubrication strategies.

- Air Leak Surveys to identify and rectify air leaks in your manufacturing processes, reducing energy consumption and improving efficiency.

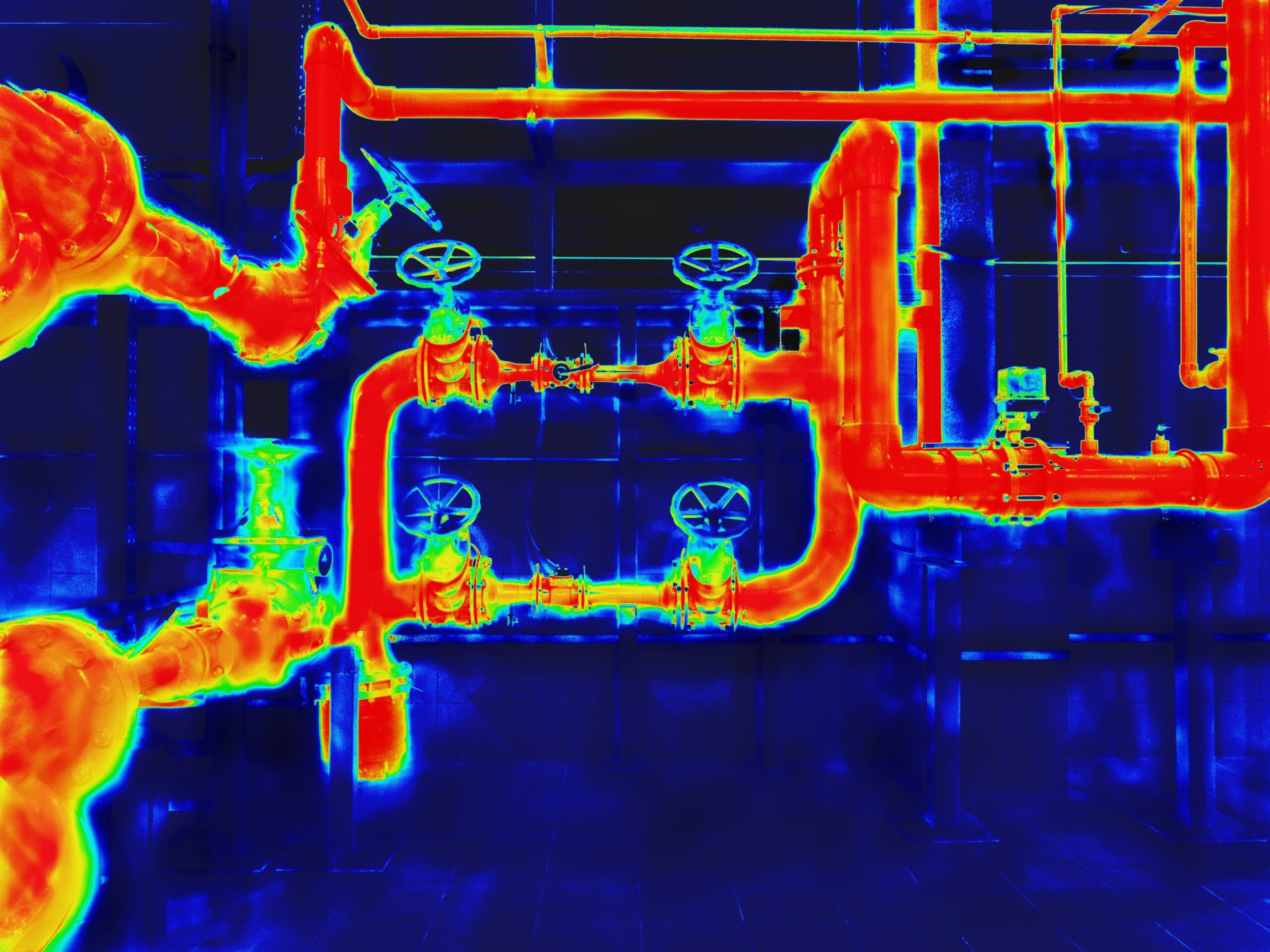

- Thermal Imaging to detect and diagnose heat-related issues in your machinery, preventing overheating and premature failure.

- Energy Surveys in order to identify and implement energy-saving measures across your manufacturing operations, reducing your energy costs and environmental impact.

How our services for the manufacturing sector can benefit you

Proactive maintenance and reduced downtime

Our comprehensive asset reliability services help you identify and address potential failures early on, preventing unplanned downtime and maximising production efficiency.

Improved asset performance and environmental sustainability

Our services promote sustainable manufacturing practices, reducing energy consumption, minimising waste, and optimising resource use.

Enhanced safety and regulatory compliance

Our services help you identify and mitigate potential hazards, safeguarding your workforce and maintaining a safe and compliant working environment.

Did you know...

60%

reduction in equipment downtime can be achieved with vibration analysis, according to a study by the National Association of Manufacturers (NAM).

32%

of workplace accidents could have been prevented by thorough risk assessments and safe systems of work, as found by the Health and Safety Executive (HSE).

6,900

enforcement actions were taken against the manufacturing industry in 2021/22, of which 3,100 were for serious breaches of regulations, according to the Health and Safety Executive.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team