Sector

Marine

Location

United Kingdom

Services

Vibration Analysis

Remote Monitoring and Data Services

Our partnership with Tidewater

Overview

Utilising vibration and stresswave spectral data collected from a vessel’s engine, our engineers were able to identify gear damage on a critical oil pump, preventing a pump failure worth £50,000. Furthermore, this could have avoided a catastrophic engine failure and replacement worth £1 million.

We provide an ongoing Condition Based Maintenance (CBM) programme to one of the world’s largest providers of offshore service vessels. Routine data is submitted on a monthly basis to establish and analyse the condition of critical assets throughout their fleet of vessels.

The challenge

The solution

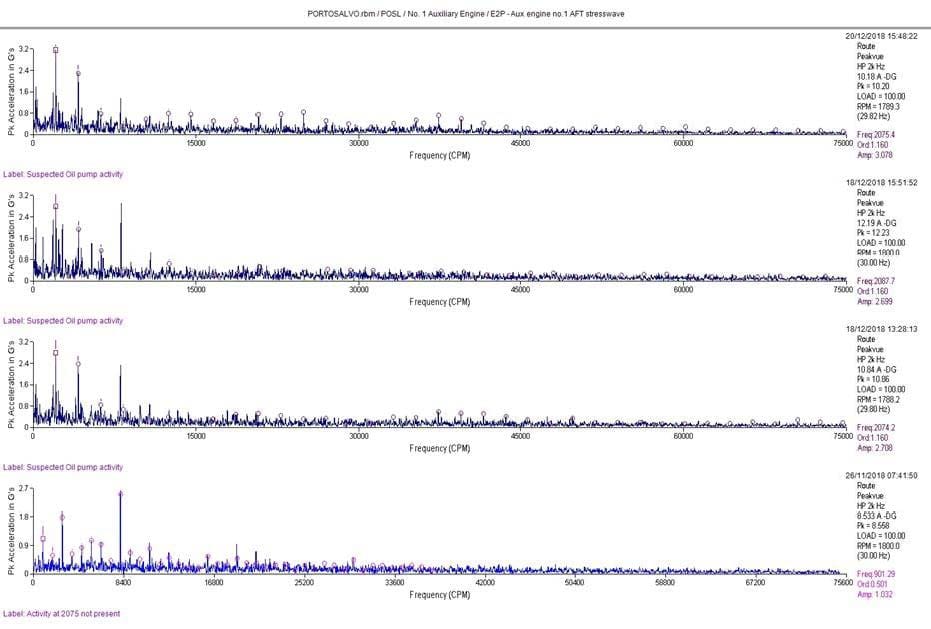

Utilising vibration and stresswave spectral data, our engineers were able to identify non-synchronous frequencies at the NDE of the engine.

These are commonly associated with rolling element bearings however, as none were located close to the measurement point, our engineers requested information from the vessel operator in regard to other components.

The result

The non-synchronous activity was identified as being 1.160 orders (2075rpm) of engine shaft running speed. Utilising the information provided by the operator, our engineers were able to identify (Item 10 – Oil pump 69 teeth so at 1800 rpm gear is doing 80 / 69 = 1.15942 x 1800 = 2087 rpm) as being the closest frequency.

Figure 1: Data from the engine NDE

The inspection of the oil pump gear found significant damage – see figure 1 & 2. The unit was replaced, and all levels returned to normal for long term continued operation with a reduction in catastrophic failure risk to both the gear, pump and risk of damaging particulate entering the engine.

Figure 2: Oil pump gear damage

Key outcomes

Prevented a pump failure worth £50,000

Prevented catastrophic engine failure worth £1 million.

Reduced the risk of damaging particulate entering the engine.

Minimised downtime and disruption to operations.

Contact us to find out more about Oil Analysis, Thermography Surveys and Remote Monitoring and Data Services.

Related Case Studies

View All Case Studies

Preserving History and Ensuring Safety with Structural Monitoring During The Jenners Building Re-development

Read more.

Vessel Downtime Avoided for UK Ferries Operator

Read more.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team